Chemical Etching: Process, Application, And Benefits

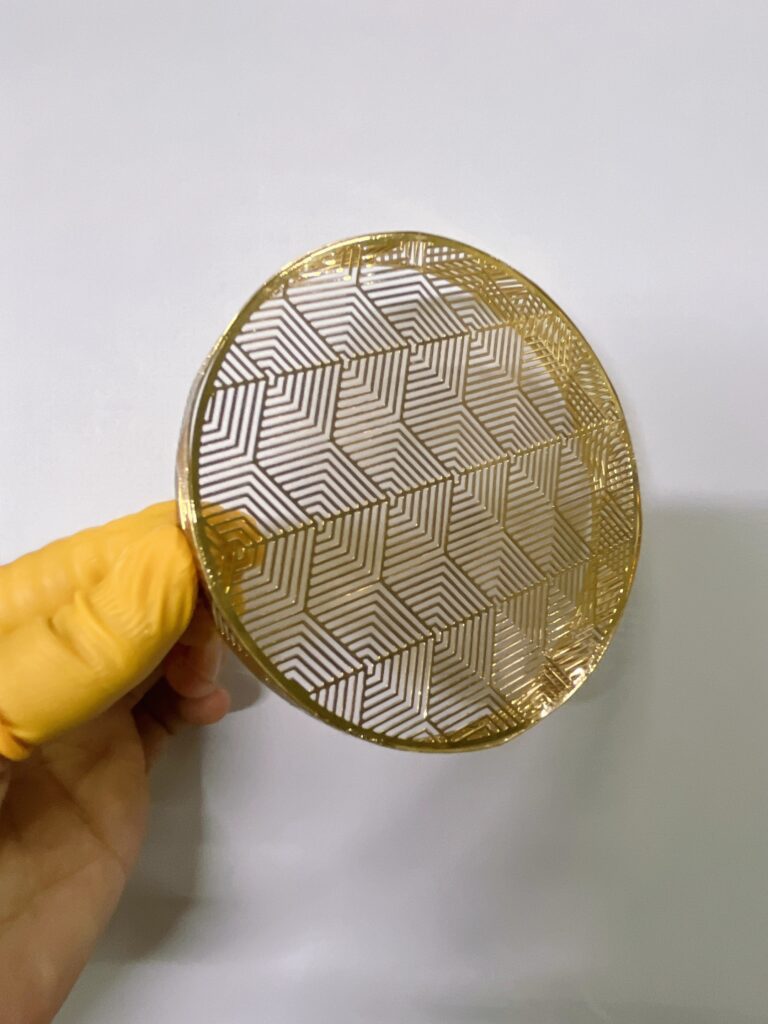

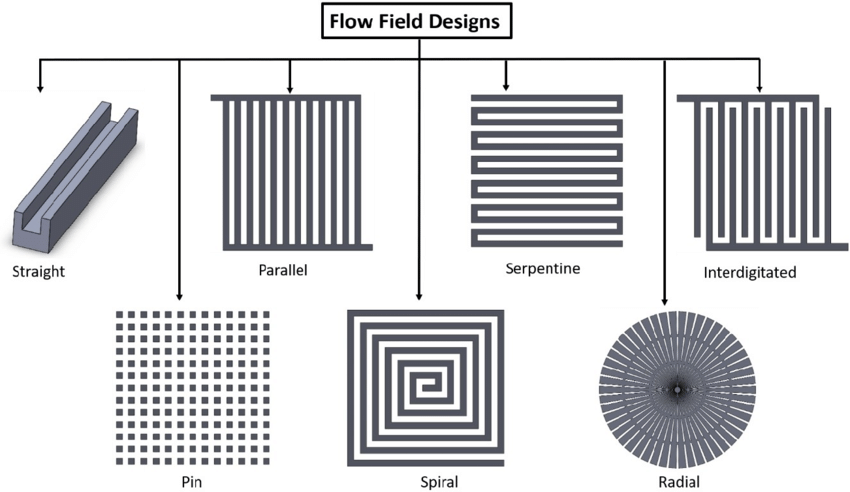

Engineers and procurement face tight deadlines, complex part geometries, and no room for error. They use traditional methods to shape the material. Sometimes, these old methods change the whole geometry of materials. The CNC is too slow, stamping needs costly dies, and laser cutting can bury your thin materials. However, the chemical etching solves those […]

Chemical Etching: Process, Application, And Benefits Read More »