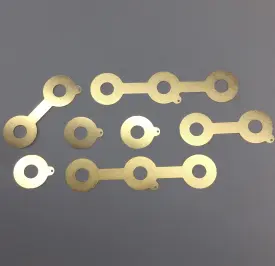

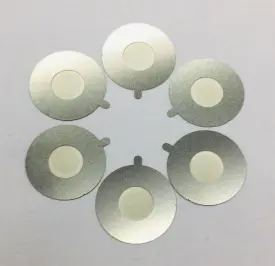

Custom Shims & Washers & Spacers

TMN manufactures various custom metal shims, gaskets, and thin washers that can be supplied flat or formed to your design specifications. We provide high-quality solutions for your needs.

Navigation

What Are Metal Shims

Metal shims are thin, flat pieces of metal used as spacers or washers between mechanical components to achieve precise alignment or spacing. They are commonly utilized in various high-tech applications where precision is critical. Metal shims help absorb impact, reduce movement or "play," and protect material surfaces from damage.

These shims are manufactured from different types of metals, including stainless steel, aluminum, brass, or copper, depending on the specific requirements of the application. The choice of metal typically depends on factors such as desired strength, corrosion resistance, conductivity, and other mechanical properties needed for the intended application.

Metal shims are widely employed in industries such as aerospace, automotive, electronics, machinery, and manufacturing, where even minor deviations in alignment or spacing can impact the performance and reliability of the equipment or components.

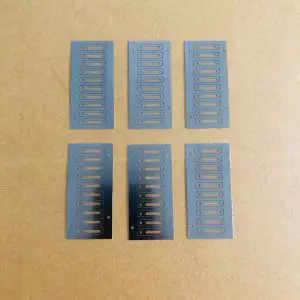

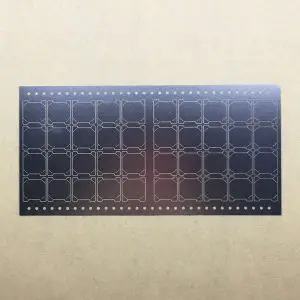

Photolithographically etched metal shims

Photolithography is a highly precise and cost-effective manufacturing process utilized by TMN to tailor metal shims for various applications. TMN offers a variety of material types, including black metals and non-ferrous metal sheets of all grades, along with corrosion-resistant, wear-resistant, and hard-to-etch metals, making them highly suitable for diverse industries.

Our chemical etching advantages

Metal grades used for metal shims

| Metal | Common Grades | Properties | Applications |

|---|---|---|---|

| Stainless Steel | 300 Series (e.g., 304, 316), 400 Series (e.g., 410, 430) | Excellent corrosion resistance, good strength, temperature resistance | Suitable for applications exposed to moisture, chemicals, or harsh environments. |

| Aluminum | Alloy 6061, Alloy 5052 | Good strength, excellent corrosion resistance, high fatigue strength, good weldability | Lightweight applications requiring corrosion resistance, fatigue resistance. |

| Brass | Alloy 260 (C26000), Alloy 360 (C36000) | Good corrosion resistance, easy machinability | Applications requiring aesthetic appeal, electrical conductivity. |

| Copper | Copper Alloy C11000 (Electrolytic Tough Pitch Copper) | Excellent electrical and thermal conductivity | Electrical and thermal applications. |

| Phosphor Bronze | Alloy 510 (C51000) | Good strength, wear resistance, corrosion resistance | High load-bearing applications, resistance to wear and fatigue. |

| Nickel Alloys | Alloy 200 (N02200), Alloy 400 (N04400) | Excellent corrosion resistance | Chemical processing, marine, aerospace applications. |

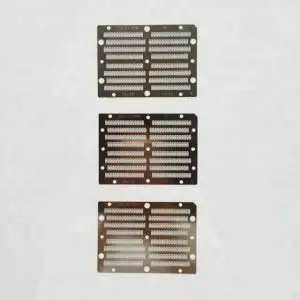

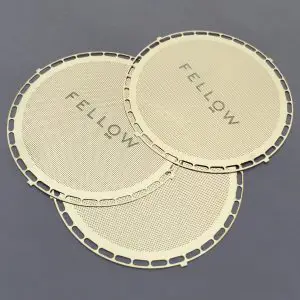

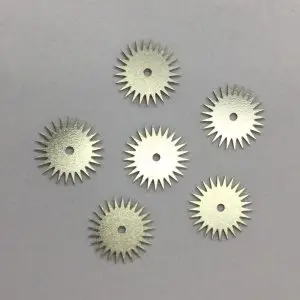

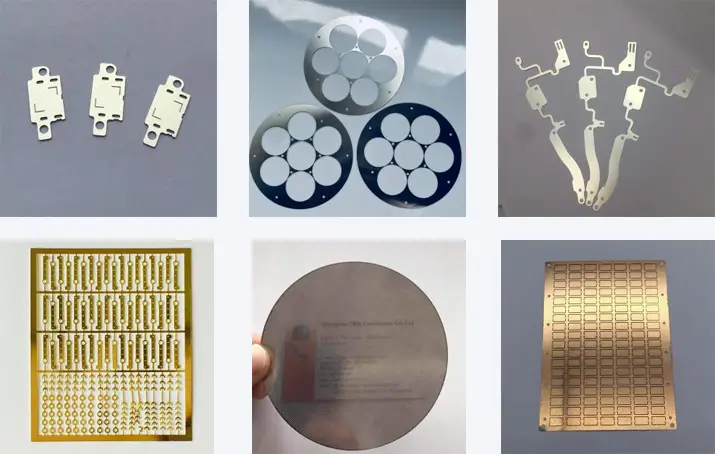

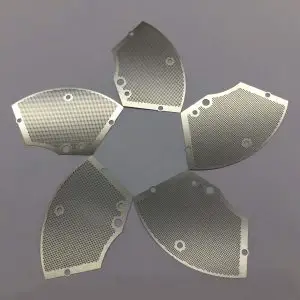

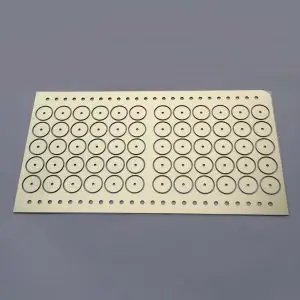

Sample of Shims & Washers & Spacers