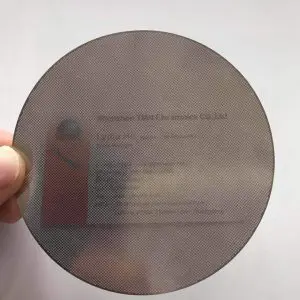

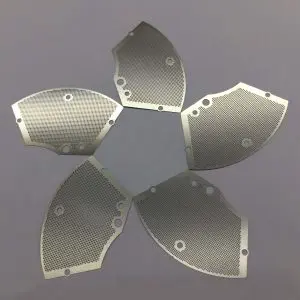

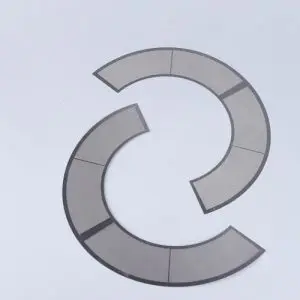

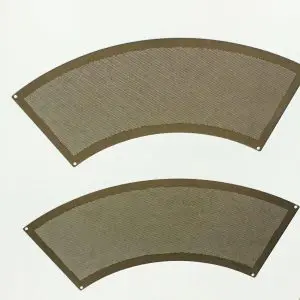

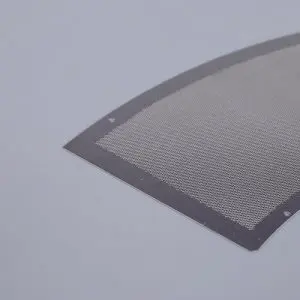

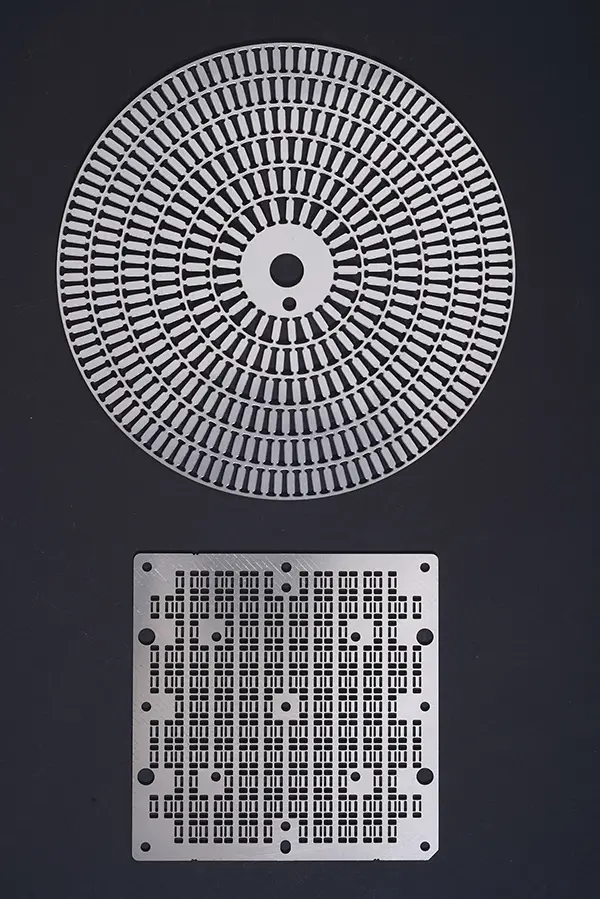

Metal filter meshes & screens

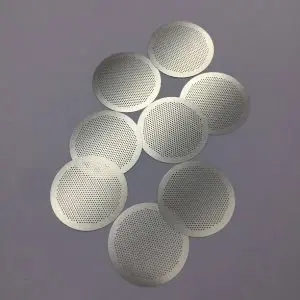

Chemical etching is a vital process in the production of metal filter screens and meshes for industries such as aerospace, automotive, and pharmaceuticals, offering precise filtration and separation capabilities. This method involves selectively etching metal substrates with specialized chemical solutions, enabling the creation of intricate patterns and precise apertures on materials like stainless steel, brass, and copper.

Chemical etching allows for customization to specific requirements, scalability for varying production volumes, and consistent quality assurance through post-processing steps like rinsing, cleaning, and inspections.

TMN Etch's advanced chemical etching service exemplifies this process, surpassing traditional perforating techniques in speed, flexibility, and cost-effectiveness, thus playing a pivotal role in meeting the demanding filtration needs of modern industrial applications.

Page Navigation

Metal Mesh: Chemical Etching vs. Traditional Stamping

Traditional Sheet Metal Perforation: Bridging Gaps in Engineering Solutions

In the field of engineering, filters, screens, and sieves are indispensable components used for separating solids from liquids or particles of different sizes. Among the current manufacturing methods, sheet metal perforation through stamping is predominant, mainly due to its cost-effectiveness in large-scale production. However, this method has inherent limitations. It lacks flexibility, struggles with complex designs, incurs high tooling costs, faces material constraints, and often produces burrs and stresses.

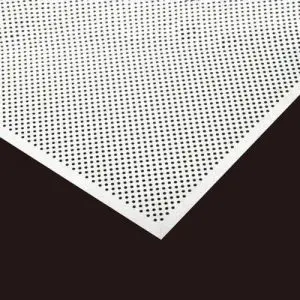

Unlocking Precision with Sheet Metal Perforation Using Photochemical Etching

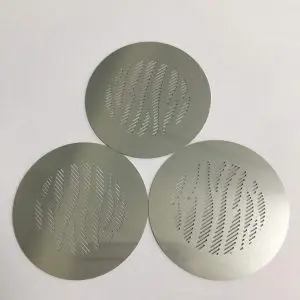

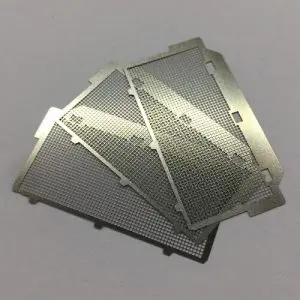

Enter photochemical etching, a transformative subtractive manufacturing process that selectively removes material from metal sheets through a chemical reaction. Here, the introduction of digital tools slashes costs and lead times while opening up avenues for unlimited complexities, structures, and geometries. By machining all mesh openings simultaneously, this method effortlessly accommodates design modifications, offering a streamlined pathway to precision and adaptability in engineering solutions.

TMN Etch's Advantages in Chemical Etching

1. Short Turnover Time for Prototypes

Begin your projects swiftly with our rapid turnaround for prototypes, ensuring efficient progress from concept to production.

2. Openings as Small as 0.1mm

Explore intricate details with openings as small as 0.1mm, allowing for precise filtration and separation capabilities in your designs.

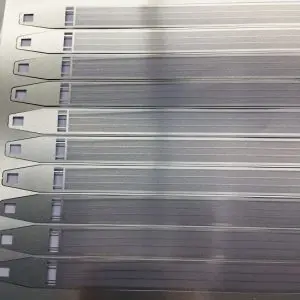

3. Unlimited Flexibility for Complex Designs

Explore the boundless possibilities of intricate and sophisticated designs, as our chemical etching process offers unparalleled flexibility to bring your vision to life.

4. Easy Design Modification

Embrace creativity without constraints by easily modifying designs during the production process, ensuring seamless adaptation to evolving project needs.

5. Tight Tolerance as +/-0.02mm

Achieve precision engineering with confidence, as our chemical etching process guarantees tight tolerances down to +/-0.02mm, meeting the most demanding specifications.

6. Diverse Choice of Metal Materials

Select from a wide range of metal materials to suit your application needs, ensuring compatibility and performance across various industries and environments.

7. Cost-Effective with Digital Tooling

Harness the power of digital tooling to reduce expenses while maintaining high-quality results, making chemical etching an economical choice for your projects.

8. 100% Burr and Stress-Free

Ensure the highest quality standards with our chemical etching process, delivering components free from burrs and stresses for superior performance and reliability.

The common materials used in TMN Etch's chemical etching filters

| 1、Stainless steel |

| 2、Copper alloy |

| 3、Brass |

| 4、Aluminum |

| 5、Molybdenum |

| 6、Titanium |

| 7、Nickel alloy |

Chemical etching stands as a beacon of versatility, effortlessly transcending boundaries to work its magic on virtually any metal type. Unlike its stamped counterpart, this method remains unshackled by the rigidity of material properties, whether hard, soft, or brittle. It emerges as the unrivaled solution, triumphing over production challenges with an unwavering finesse, regardless of the material's temperament.

What are the applications that filter mesh and screen used for ?

| 1、Juice & coffee makers |

| 2、Demister and Oil Separation Devices |

| 3、Household appliances |

| 4、Speaker grilles |

| 5、Insect and Dust Prevention Equipment |

| 6、Isolate Blood Cells and Plasma |

| 7、Medical devices |

| 8、Printers |

| 9、Water purifiers |

| 10、Optical instruments |

| 11、High-precision engineering filtration |

| 12、Hair dryer |

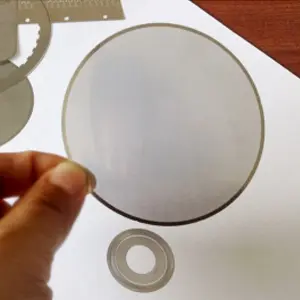

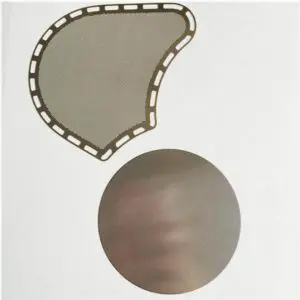

Samples of TMN etched

Send us a message