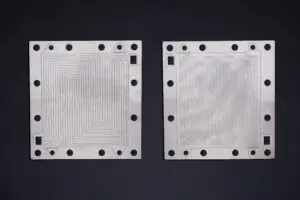

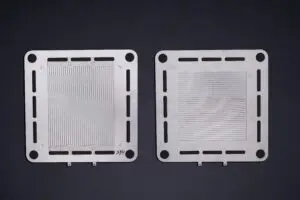

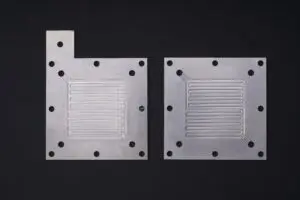

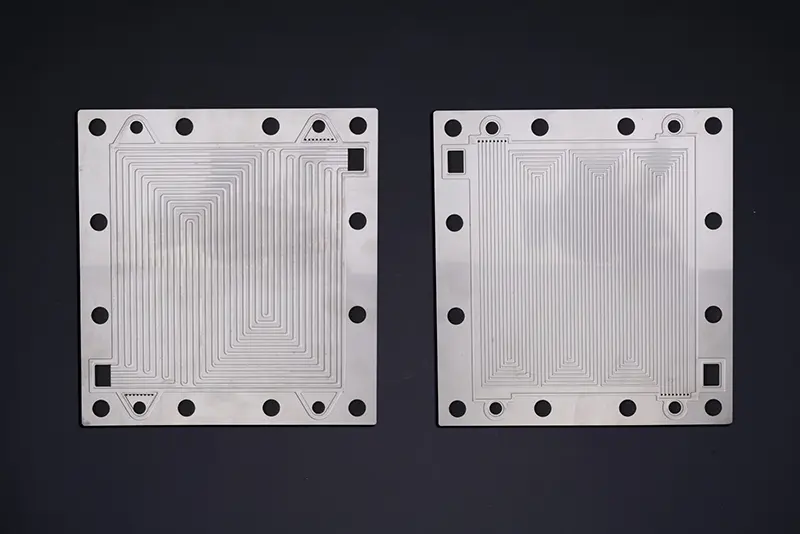

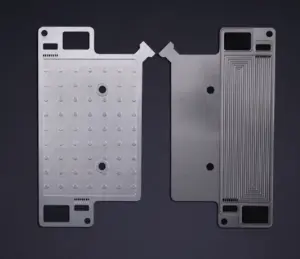

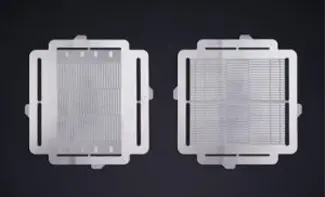

Bipolar Plates

TMN supply leading solutions of chemical etched metallic bipolar plates that used for power fuel cell stacks and water electrolyzers.

Page wizard

What’s a bipolar plates ?

Bipolar plates, also known as channel plates, are flat structures with multiple channels meticulously crafted to direct the movement of fluids or gases. Widely employed in liquid and gas transmission systems like pipelines, pumping stations, and cooling systems, these plates play a pivotal role in influencing critical parameters such as flow velocity, flow rate, and pressure loss.

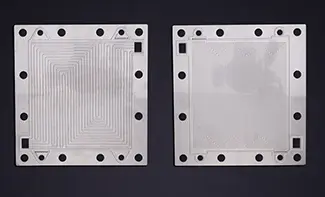

What can TMN photo chemical etching factory do ?

At TMN, we take pride in our role as a cutting-edge photochemical etching factory, boasting a highly skilled team of professionals dedicated to delivering top-notch solutions. Our focus lies in achieving unparalleled precision and handling the intricate geometrical complexities of bipolar plates with finesse.

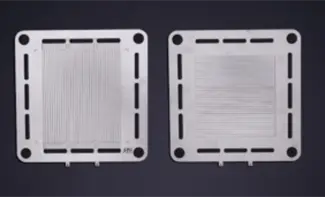

Diving into the realm of raw materials, TMN has successfully etched a diverse range, including:

- Aluminum

- Titanium - Available in Grade 1, Grade 2, and Grade 6

- Stainless Steel 316L - Varied thickness ranging from 0.1mm to 3.0mm

- Nickel

Our capabilities extend to etching both curved and straight channels across the entirety of sheets, allowing for a seamless integration of intricate designs. Moreover, we meticulously etch to the specified depth thickness, ensuring precision and reliability in every project.

At TMN, we don't just etch – we innovate, providing you with unparalleled solutions for your photochemical etching needs. Experience the epitome of excellence as we navigate the complexities of bipolar plates with expertise and precision.

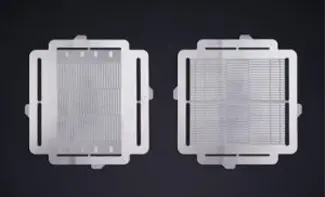

What are the advantages of TMN etched bipolar plates ?

1. Comprehensive Support for Prototype Development and High-Volume Production:

TMN provides robust support for both prototype development and high-volume production processes.

2. Mature Quality Control and Cost Control Systems:

We boast a mature quality control system and an efficient cost control system, ensuring tight tolerances, fast lead times, and competitive costs.

3. High-Resolution Optical Inspection:

Our capabilities include high-resolution optical inspection, ensuring meticulous scrutiny and precision in the evaluation of our products.

4. Integrated Traceability:

TMN offers integrated traceability, allowing for a seamless tracking system throughout the production process, ensuring transparency and accountability.

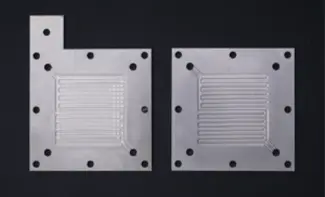

What are the secondary processes that TMN photo chemical etching can provide to etched bipolar plates?

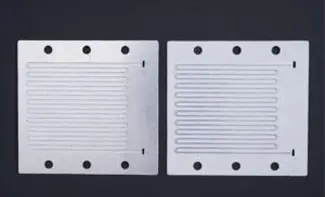

1. Diffusion Bonding:

TMN excels in diffusion bonding techniques, ensuring a strong and reliable bond between different materials. This process enhances the structural integrity of bipolar plates, contributing to improved performance.

2. Metal Welding:

Our capabilities extend to precise metal welding, allowing for the seamless integration of various components. This enhances the overall stability and conductivity of bipolar plates.

3. Metal Forming:

TMN's expertise in metal forming ensures that bipolar plates can be shaped to meet specific design requirements. This flexibility opens up new possibilities for optimizing plate geometries and overall performance.

4. Laser Cutting:

TMN's expertise in metal forming ensures that bipolar plates can be shaped to meet specific design requirements. This flexibility opens up new possibilities for optimizing plate geometries and overall performance.

5. Laser Cutting:

To enhance conductivity and corrosion resistance, TMN offers gold plating services. This additional layer adds a protective and conductive element to the bipolar plates, extending their lifespan and reliability.

What are the usage of fuel cell bipolar plates that TMN etched ?

1. Portable Power Banks for Field Work or Military Operations:

TMN's etched bipolar plates power portable solutions for field work and military applications.

2. 50–1,000 kW Stationary Power Generation Equipment:

Experience the reliability of TMN's etched bipolar plates in stationary power generation units ranging from 50 to 1,000 kW.

3. Future Electric Vehicles' Power Source:

TMN's advanced technology contributes to the development of efficient power sources for the electric vehicles of tomorrow.

4. Power Supply for Mobile Communication Equipment:

Trust TMN's etched bipolar plates to provide a robust power supply solution for mobile communication devices.

5. Power Supply for Mobile Communication Equipment:

Elevate performance in the aerospace sector with TMN's precision-crafted bipolar plates.

6. Automotive Field Advancements:

TMN's etched bipolar plates play a crucial role in advancing technology within the automotive industry.

7. Aircraft Applications:

Experience the reliability and innovation of TMN's etched bipolar plates in various aircraft applications.

Send us a message