PCB Level EMI/RFI Shielding

We have years of industry experience in PCB-level shielding, focusing on producing custom PCB-level EMI/RFI shielding cans for various electronic applications using photochemical etching technology.

Navigation

Understanding PCB-Level EMI/RFI Shielding

EMI shielding, also known as electromagnetic shielding, is crucial for protecting electronic components from interference. It involves using special materials and techniques to block outside electromagnetic signals and prevent internal interference.

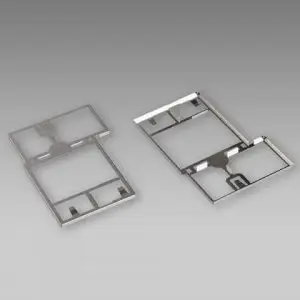

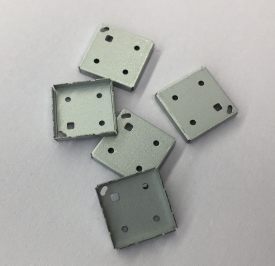

In PCBs, shielding is often done using PCB Grade EMI/RFI Shielding Cans. These are metal enclosures, usually made of aluminum or nickel-iron alloy, designed to shield circuit boards from electromagnetic and radio frequency interference.

These shielding cans keep electronic devices safe from interference, ensuring they work properly, especially in high-frequency circuits. By blocking electromagnetic radiation from the environment or other devices, they help maintain the stability and performance of the circuit board.

PCB Grade EMI/RFI Shielding Cans are installed on circuit boards using specific connectors or soldering techniques to ensure they work effectively. Dealing with electromagnetic compatibility (EMC) issues and using proper shielding measures are vital for designing reliable electronic devices, making these shielding cans essential components in electronics engineering.

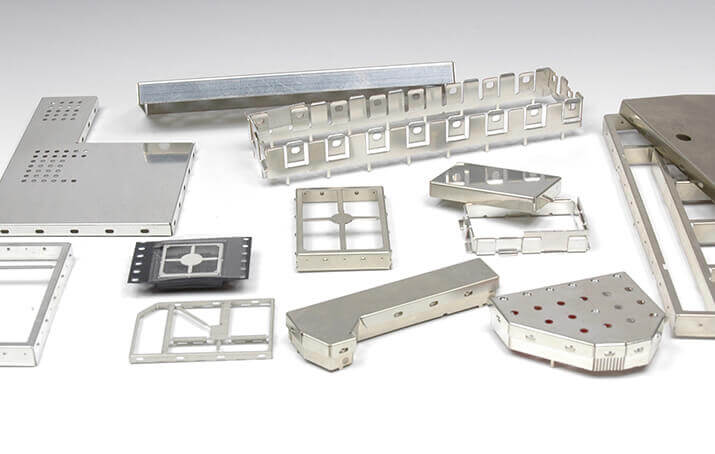

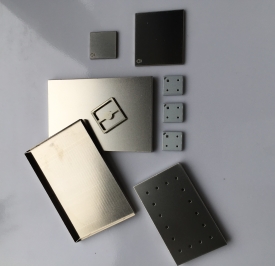

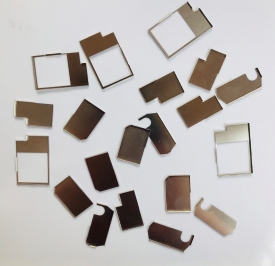

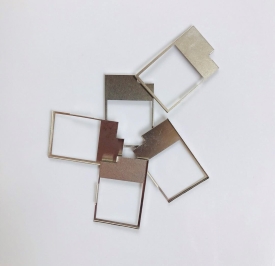

Chemically etched PCB shielding can

TMN can chemically etch any shielding solution you need.

Benefits of the Etching Process

Metal Grades for EMI and RFI Shielding

| Material | Characteristics | Applications |

|---|---|---|

| Copper | - EMI/RFI Shielding Frame/Blank: Cu-C7521-H, Cu-C7521-OH, Copper-Nickel-Zinc Alloy, Nickel Silver | - Frame/blank for shielding - Shielding cover for bending process |

| - EMI/RFI Shielding Cover: SUS304R-1/2H (for bending process), SUS304R-1/4H, Tin-plated Steel | ||

| Tin-plated Steel | - EMI/RFI Shielding Used for PCB Assembly: Provides effective shielding with corrosion resistance | - PCB assembly |

| Nickel Silver | - EMI/RFI Shielding Used for PCB Assembly: Offers excellent electrical conductivity and corrosion resistance | - PCB assembly |

| Nickel Plated Steel | - EMI/RFI Shielding Used for PCB Assembly: Provides strong shielding with enhanced durability | - PCB assembly |

| Copper-Nickel-Zinc Alloy | - EMI/RFI Shielding Frame/Blank: Offers a combination of conductivity and corrosion resistance | - Frame/blank for shielding |

| SUS304R Stainless Steel | - EMI/RFI Shielding Cover: Provides durability and corrosion resistance, suitable for bending processes | - Shielding cover for bending process |

EMI & RFI Shielding Applications

Description of Custom EMI/RFI Shielding

| 1、Drawings are needed at the format of DWG/DXF/3D file. |

| 2、Production Volume,1800 square meter/day |

| 3、Inspection equipment,Two-dimension inspection machine |

| 4、Packing method ,tape and reel ,blister package . |

| 5、Sample lead time ,3-5 days |

| 6、Industry Standards,ISO 9001: 2015 |

EMI & RFI Shielding Samples

We provide a range of EMI/RFI shielding solutions including shielding blanks, tin-plated shielding covers, PCB shielding cans, customized solutions, and more.

Send us a message