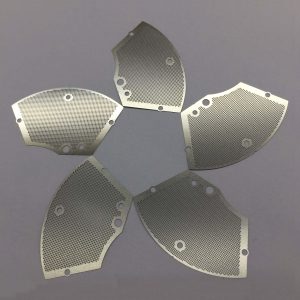

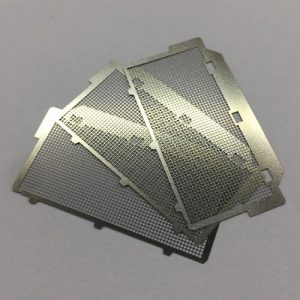

TMN custom metal mesh filter sample

Custom Mesh Filter

What is a mesh filter?

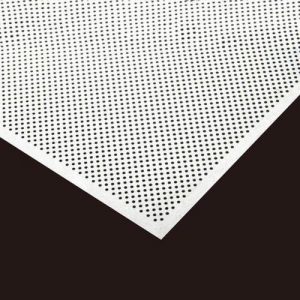

A metal mesh filter is a type of filtration system commonly used to separate particles or impurities from air or liquids. It consists of a network of interwoven metal wires or strands, creating a mesh pattern with specific size openings. The size and density of these openings determine the filter's effectiveness in trapping particles.

Metal mesh filters are used in various applications, including air filtration in HVAC systems, industrial processes, automotive filters, and kitchen range hoods. They are known for their durability, resistance to high temperatures, and reusability, which make them an attractive choice for environments where traditional filters might degrade or require frequent replacement.

What is filter mesh size?

Filter mesh size refers to the size of the openings in a mesh filter, typically measured in terms of the number of openings or "apertures" per unit of measurement. This size determines the filter's capacity to allow certain particles to pass through while blocking others.

In metal mesh filters, the mesh size is usually quantified by:

Mesh Count: This indicates the number of openings per linear inch in both horizontal and vertical directions. For example, a mesh size of "100" means there are 100 openings per inch.

Aperture Size: This represents the size of individual openings in the mesh, usually measured in micrometers (µm) or millimeters (mm). A larger aperture size allows bigger particles to pass through, while a smaller aperture size captures finer particles.

The filter's effectiveness in capturing or separating particles depends on its mesh size. A higher mesh count with smaller apertures is used for finer filtration, such as in laboratory applications or fine particulate air filtration. Lower mesh counts with larger apertures are used when a broader range of particles needs to be filtered out, such as in industrial settings or HVAC systems.

What does mesh mean in filters?

"mesh" in filters refers to the structural design that enables the filter to selectively allow or block particles based on their size. It is a crucial component in many filtration systems, from industrial to household applications.

What is finer 100-mesh or 200 mesh?

A 200-mesh filter is finer than a 100-mesh filter. The mesh size represents the number of openings per linear inch in a filter. Therefore, a 200-mesh filter has 200 openings per inch, while a 100-mesh filter has only 100 openings per inch. Because a 200-mesh filter has more openings within the same area, the apertures or holes in the filter are smaller, allowing it to trap smaller particles compared to a 100-mesh filter.

Thus, if you are filtering finer particles or looking for higher filtration precision, a 200-mesh filter would be more suitable, while a 100-mesh filter would be better for filtering larger particles or providing a coarser filtration.

Which is finer 100-mesh or 400 mesh?

A 400-mesh filter is finer than a 100-mesh filter. The mesh size refers to the number of openings or "apertures" per linear inch in a mesh. Therefore, a 400-mesh filter has 400 openings per inch, while a 100-mesh filter has 100 openings per inch. Since a 400-mesh filter has more openings within the same area, it has smaller apertures, allowing it to filter out finer particles compared to a 100-mesh filter.

In practical terms, if you're aiming to filter out finer particles, you'd opt for a 400-mesh filter. If you're interested in coarser filtration, the 100-mesh filter would be more appropriate. The difference in mesh size impacts the filter's ability to trap or allow certain particle sizes through, making it an important consideration in various filtration applications.

What is the purpose of a mesh filter?

A metal mesh filter serves to separate, capture, or remove particles, impurities, or debris from air or fluids in a variety of settings. Its primary purpose is to allow smaller particles to pass through while blocking larger ones, achieving a desired level of filtration for a specific application.

Here are some key purposes and uses for metal mesh filters:

- Air Filtration: In heating, ventilation, and air conditioning (HVAC) systems, metal mesh filters help clean the air by trapping dust, pollen, and other airborne particles. They can also be found in air purifiers and industrial ventilation systems.

- Fluid Filtration: Metal mesh filters are used in various fluid filtration processes, including in automotive oil filters, industrial fluid systems, and hydraulic applications. They help remove contaminants to protect equipment and ensure efficient operation.

- Cooking and Kitchen Applications: In kitchen range hoods and exhaust systems, metal mesh filters trap grease and food particles, preventing them from accumulating in the ventilation system and reducing fire hazards.

- Industrial Applications: In industrial settings, metal mesh filters are employed to separate particles from liquids, such as in chemical processing, oil refining, and water treatment. They help maintain product quality and protect equipment from damage due to contaminants.

- Reusable Filtration: Metal mesh filters are valued for their durability and reusability. Unlike disposable filters, they can be cleaned and reused, making them cost-effective and environmentally friendly over time.

In summary, the purpose of a metal mesh filter is to provide effective filtration by trapping particles of various sizes while allowing air or fluids to flow through. The range of applications is wide, from HVAC systems and industrial processes to kitchen exhausts, demonstrating the versatility and reliability of metal mesh filters in various settings.

Custom metal mesh filters?

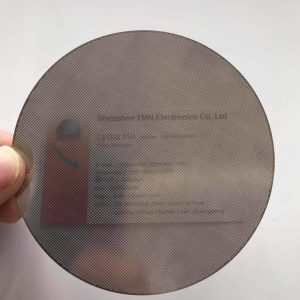

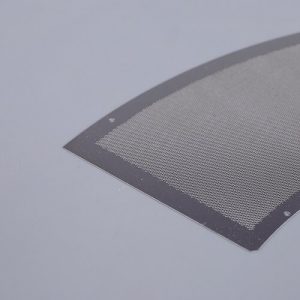

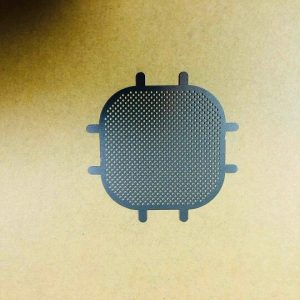

If you're interested in custom metal mesh filters, TMN's is a professional manufacturer specializing in photochemical etching of metal filters. TMN's offer integrated manufacturing services. Custom metal mesh filters are used in a variety of fields, including industrial, medical, automotive, electronics, and aerospace applications. The advantage of custom filters is that TMN's can be tailored to specific requirements in terms of size, thickness, mesh size, and material.

The process for creating custom metal mesh filters generally involves the following steps:

Design Phase: This involves designing the filter's dimensions, shape, and mesh size according to your specific requirements. Photochemical etching technology allows for high-precision designs, including complex patterns and fine details.

Material Selection: Different applications may require different metal materials. Common choices include stainless steel, copper, aluminum, and titanium. Each material has unique properties such as corrosion resistance, temperature tolerance, and mechanical strength.

Manufacturing Process: Photochemical etching is a precise and flexible manufacturing technique that uses chemical methods to remove part of the metal surface to create the desired pattern. This process achieves high precision without causing burrs or deformation.

Quality Control: To ensure the filters meet the design specifications, manufacturers typically conduct rigorous quality checks. This may include measuring mesh size, inspecting surface quality, and testing the filter's performance.

If you're interested in custom metal mesh filters, you can contact TMN's for consultation. TMN's will work with you to design and manufacture filters to meet your specific needs. Custom filters ensure that the product fits your application perfectly, providing optimal performance and durability.

Learn more about TMN’s photo etching metal filter customization capabilities>>>

Send us a message