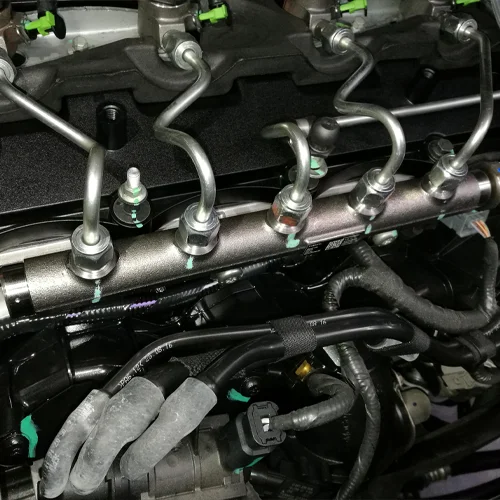

car etching

Accelerating the

Automotive Industry

TMN Photochemical Etching: Your trusted partner for luxury and high-end global automotive manufacturers, offering a diverse range of F1 and automotive component solutions.

Trusted industry-leading brand

Advantage

Partnering with TMN offers numerous advantages

Quality Assurance

Our commitment to quality approaches Six Sigma standards, ensuring unparalleled levels of repeatability in the chemical etching industry.

Prototype Etching

Utilizing the same machinery and process technology, we seamlessly transition from prototype to full-scale production, maintaining consistency and quality throughout.

Customer-Centric Approach

We prioritize customer satisfaction while ensuring uncompromised quality, assisting clients in effectively reducing costs during the development phase.

Wide Material Range

Benefit from our extensive range of materials, allowing for flexibility and customization to meet your specific requirements.

High Precision

Our advanced technologies enable us to achieve the highest levels of precision, ensuring that every component meets exact specifications with accuracy and consistency.

ISO 9001:2015 Certification

Rest assured with our ISO 9001:2015 certification, demonstrating our commitment to maintaining stringent quality management systems and continuous improvement processes.

Experience the TMN advantage and unlock the full potential of chemical etching for your aerospace and military component manufacturing needs.

Etched Automotive Parts

TMN is a leading specialist in metalworking services, focusing on chemical etching processes. Here's an overview of common automotive components we can produce:

Speaker Grilles

Precision etching ensures optimal sound transmission without compromising design integrity.

Custom Metal Shims

Tailored to exact specifications, our shims guarantee perfect fitment for critical automotive assemblies.

Bipolar Plates

Engineered with precision etching for superior performance in fuel cell and battery systems.

PCB Shielding Cans

Our etched shielding cans provide reliable electromagnetic interference (EMI) protection for sensitive electronics in vehicles.

Brand Labels

Etched branding offers durable, high-quality identification solutions for automotive OEMs and aftermarket applications.

Encoder Disks

Precision etching enables the production of accurate encoder disks for automotive sensor systems, ensuring precise position feedback.

Flat Springs

Etched to precise tolerances, our flat springs offer consistent performance in automotive suspension and braking systems.

Electrical Connectors

Etched contacts ensure reliable electrical conductivity, critical for automotive wiring harnesses and electrical systems.

These are just a few examples of the automotive components we can manufacture through chemical etching. If you require custom solutions for other parts, don't hesitate to reach out to us.

Common Metal Materials for Automotive Components

TMN is a professional chemical etching enterprise with expertise in a wide range of metal materials. Here are some commonly used metal materials for automotive parts:

Titanium

Known for its high strength-to-weight ratio and corrosion resistance, titanium is often used in automotive components requiring lightweight yet durable solutions.

Stainless Steel

Renowned for its excellent corrosion resistance and strength, stainless steel is commonly used in automotive parts that require durability and aesthetic appeal.

Copper

With its excellent electrical conductivity and thermal properties, copper is frequently used in automotive electrical components and wiring systems.

Nickel

Known for its corrosion resistance and ability to withstand high temperatures, nickel is used in various automotive applications, including exhaust systems and battery components.

These four materials represent the most common options for automotive parts, but TMN offers a wide selection of metal materials beyond these options. Feel free to contact us for any other metal material preferences or inquiries.

Why Use Chemical Etching for Automotive Component Manufacturing?

Chemical etching offers distinct advantages over traditional machining techniques for automotive parts production. Unlike traditional methods, it excels at creating intricate designs with precise detail, making it ideal for components like speaker grilles and encoder disks.

It also minimizes material wastage, reducing production costs, especially for expensive materials like titanium or stainless steel. Additionally, its non-contact process ensures minimal risk of mechanical distortion, maintaining part integrity for critical automotive applications.

Overall, chemical etching provides automotive manufacturers with a cost-effective, precise, and scalable manufacturing solution that surpasses the limitations of traditional machining methods.

Get instant Quote