Metal filter mesh is precisely manufactured from various metal materials and is widely used in different fields. So, why choose metal filter mesh? TMN will provide a detailed introduction to the functions, applications, materials, and manufacturing processes of metal filter mesh to help you better understand the advantages of this product.

What Are the Functions and Applications of Metal Filter Mesh?

Metal filter mesh has extensive and diverse uses across various industries. It is not only a tool for filtration and separation but also a core component in many industrial processes due to its versatility and durability. Here is a detailed introduction to the applications of filter mesh customized by TMN’s clients:

1. Industrial Filtration

Metal filter mesh is widely used in industrial production for filtering various liquids and gases. It effectively removes solid particles from liquids or gases, ensuring the purity of the medium. For example:

Chemical Industry: In chemical production, metal filter mesh is used to filter reaction products, separate catalysts, and remove impurities, ensuring the purity of chemical reactions and product quality.

Petroleum and Natural Gas Industry: It is used for oil-gas separation and filtration, removing impurities from pipelines, preventing equipment blockage or wear, thereby extending equipment lifespan.

Pharmaceutical Industry: Metal filter mesh is used in liquid filtration, removing tiny particles during production to ensure the purity and safety of pharmaceutical products.

2. Water Treatment

Metal filter mesh plays a crucial role in water treatment systems, particularly in water purification, wastewater treatment, and seawater desalination. It effectively filters out suspended solids, particles, and microorganisms in water, ensuring that the water quality meets drinking or industrial water standards. Specific applications include:

Drinking Water Treatment: Filtering out sand, rust, microorganisms, and other impurities from water, improving water cleanliness and safety.

Wastewater Treatment: In wastewater treatment plants, metal filter mesh is used to remove suspended particles and solid pollutants from wastewater, preventing contaminants from entering the environment or downstream processes.

3. Air Filtration

In air filtration systems, metal filter mesh is commonly used to filter dust, particles, and other pollutants from the air, especially in environments requiring high cleanliness, such as electronics manufacturing, pharmaceuticals, and food processing industries:

HVAC Systems: In heating, ventilation, and air conditioning systems, metal filter mesh is used to filter dust and particles from the air, ensuring indoor air quality and the normal operation of the system.

Electronics Industry: In clean rooms, metal filter mesh is used to filter air, preventing tiny particles from contaminating the manufacturing process of precision electronic components.

4. Applications in High-Temperature and Corrosive Environments

Due to the excellent high-temperature and corrosion resistance of metal filter mesh, it is widely used in environments with high temperatures and strong corrosion. For example:

High-Temperature Gas Filtration: In high-temperature industrial processes such as steel and glass manufacturing, metal filter mesh is used to filter solid particles from high-temperature gases, protecting equipment and the environment.

Corrosive Media Filtration: In chemical plants, metal filter mesh is used to filter corrosive media such as strong acids and alkalis, extending the service life of filtration equipment.

5. Food and Beverage Industry

In the production of food and beverages, metal filter mesh is used to filter raw materials, process liquid foods, filter oils, and more, ensuring product purity and safety. For example:

Food Processing: In the production of edible oil, metal filter mesh is used to filter impurities, ensuring the clarity and quality of the oil.

Beverage Production: In the production of beverages such as beer and juice, metal filter mesh is used to remove particulate impurities, ensuring the purity and taste of the drinks.

6. Electronics and Precision Manufacturing

In the manufacturing of electronic components and precision mechanical processing, metal filter mesh is used to protect equipment and improve product quality. For example:

Semiconductor Manufacturing: In the semiconductor manufacturing process, metal filter mesh is used to filter chemicals and air, preventing tiny particles from contaminating the wafers.

Precision Machinery: In precision mechanical processing, metal filter mesh is used to filter coolant, removing tiny particles generated during cutting, ensuring machining accuracy.

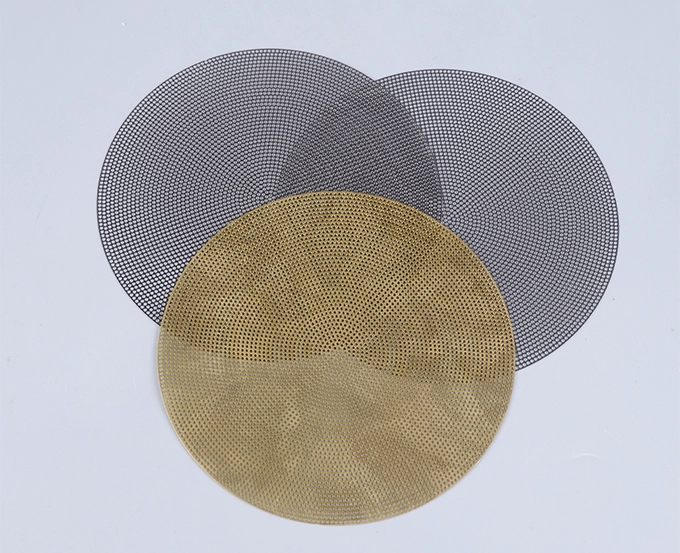

Material Selection for Metal Filter Mesh

The performance of metal filter mesh largely depends on the characteristics of the selected material. Different materials offer unique advantages and suitability, making it crucial to choose the appropriate material for various applications. TMN has a large metal warehouse, providing a wide range of high-quality materials for manufacturing metal filter mesh, including stainless steel 300 series, copper, brass, aluminum, and titanium. Below is a detailed introduction and selection criteria for these materials:

1. Stainless Steel 300 Series

The stainless steel 300 series is one of the most commonly used materials for metal filter mesh. This series primarily includes grades such as 304, 316, and 316L, each with its unique properties.

304 Stainless Steel: This is the most widely used type of stainless steel, known for its good corrosion resistance, strength, and toughness. 304 stainless steel performs well in many applications, particularly in general environments such as water treatment and food processing. It can resist most oxidizing acids and is easy to form and weld.

316 Stainless Steel: Compared to 304 stainless steel, 316 stainless steel has added molybdenum, which further enhances its corrosion resistance, especially in chloride environments (like seawater). 316 stainless steel is suitable for more demanding chemical, marine, and pharmaceutical environments.

316L Stainless Steel: 316L is the low-carbon version of 316 stainless steel, offering better resistance to intergranular corrosion. It is ideal for applications requiring high welding performance, particularly in chemical and pharmaceutical equipment.

Applicable Fields: The stainless steel 300 series is suitable for environments requiring high corrosion resistance and strength, such as chemical processing, food and beverage, pharmaceutical equipment, and water treatment systems.

2. Copper

Copper offers unique advantages in certain specialized filtration applications due to its excellent electrical and thermal conductivity. Copper filter mesh is commonly used in fields requiring high conductivity or antibacterial properties.

Characteristics: Copper has good ductility, antibacterial properties, and high corrosion resistance, particularly performing well in non-oxidizing acids and alkaline solutions. Copper also has natural antibacterial properties, effectively inhibiting the growth of microorganisms.

Applicable Fields: Electrical industry, electronic equipment, pharmaceutical industry, and food industry, particularly in applications requiring bacterial growth inhibition or high conductivity.

3. Brass

Brass, an alloy of copper and zinc, is widely used in the manufacturing of metal filter mesh due to its excellent mechanical properties and corrosion resistance.

Characteristics: Brass offers good wear resistance, corrosion resistance, and high strength, along with being easy to machine. Its aesthetically pleasing color also makes it popular for certain decorative filtration applications.

Applicable Fields: Marine engineering, instrumentation manufacturing, decorative filtration applications, and potable water systems.

4. Aluminum

Aluminum is a lightweight, corrosion-resistant metal material, widely used in applications requiring low weight, good conductivity, or high corrosion resistance.

Characteristics: Aluminum is lightweight, with a density only one-third that of stainless steel, yet it still possesses good strength and corrosion resistance. It has excellent thermal and electrical conductivity and maintains its toughness at low temperatures, making it ideal for use in refrigeration equipment and the aerospace industry.

Applicable Fields: HVAC systems, aerospace, heat exchangers, refrigeration equipment, lightweight industrial design.

5. Titanium

Titanium is an extremely corrosion-resistant metal with a very high strength-to-weight ratio, making it especially suitable for extreme environments and high-performance applications.

Characteristics: Titanium has outstanding corrosion resistance, particularly in harsh environments such as seawater, strong acids, and strong alkalis. It has a lower density than steel but offers high strength, making it highly valued in applications that require high strength and low weight. Titanium also has exceptional biocompatibility, making it a common material in medical devices.

Applicable Fields: Aerospace, marine engineering, chemical processing, high-end medical equipment, seawater desalination, nuclear industry.

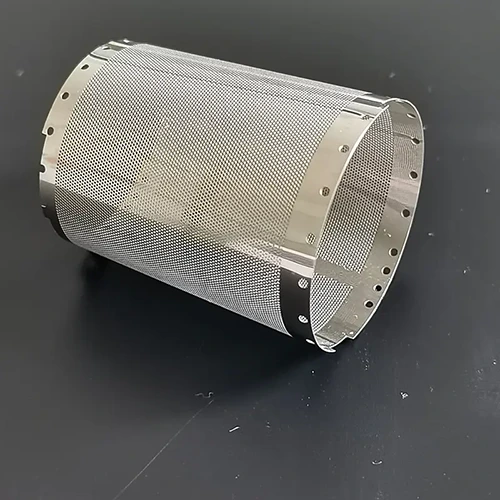

Manufacturing Process of Metal Filter Mesh

The manufacturing process of metal filter mesh is diverse, with different techniques suited to various types of materials and final product requirements. Common processes include stamping, laser cutting, weaving, and photochemical etching. Each process has its unique characteristics and applications. Below is a detailed introduction to these processes, with a focus on the advantages of TMN’s photochemical etching process:

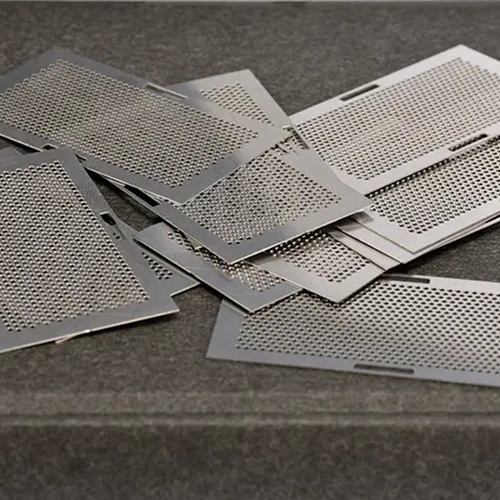

1. Photochemical Etching Process

TMN’s photochemical etching process is a highly precise and flexible manufacturing technique, particularly suitable for small-batch, multi-variety, and high-precision production of metal filter mesh.

Characteristics of TMN’s Photochemical Etching Process:

No Tooling Costs: Unlike the stamping process, photochemical etching does not require expensive molds, reducing upfront development costs, making it especially suitable for samples and small-batch production.

High Precision: Photochemical etching can achieve a high precision of +/- 0.03mm, ideal for producing filter mesh with extremely fine apertures. TMN’s etching process can handle minimum aperture sizes down to 0.01mm, ensuring the precision and consistency of the filter mesh.

Complex Pattern Processing: It can easily handle complex geometric shapes and irregular designs, making it suitable for producing filter mesh with special design requirements.

Material Versatility: TMN’s photochemical etching process is applicable to a wide range of metal materials, including stainless steel, copper, aluminum, and others, meeting the material needs of various customers.

High Surface Finish: The photochemical etching process does not generate mechanical stress, resulting in a smooth surface without burrs, ensuring the quality and durability of the filter mesh.

Eco-Friendly Process: TMN’s photochemical etching process uses environmentally friendly technology, reducing waste production and meeting modern environmental standards.

2. Stamping Process

The stamping process is a traditional and widely used manufacturing method, primarily for large-scale production of metal filter mesh. Using molds and presses, metal sheets are punched to form the desired filter mesh structure.

Characteristics:

Suitable for Large-Scale Production: Due to the high cost of mold manufacturing, this process is more suitable for mass production.

Limitations: The design of stamping molds is complex, costly, and challenging to produce high-precision, small-aperture filter mesh. Additionally, the stamping process can easily produce burrs, affecting the surface quality of the product.

3. Laser Cutting Process

The laser cutting process uses a high-energy laser beam to cut metal materials, forming the desired filter mesh structure. This method is highly flexible and capable of handling a wide variety of complex patterns.

Characteristics:

High Precision: Laser cutting can achieve high-precision cuts, making it suitable for manufacturing intricate patterns and structures.

Strong Material Compatibility: It can cut almost any metal material, including stainless steel, copper, aluminum, and more.

Drawbacks: Laser cutting has relatively low production efficiency and is not ideal for mass production. Additionally, the cutting edges may develop a heat-affected zone, potentially impacting the material’s performance.

4. Weaving Process

The weaving process involves interweaving metal wires to create a mesh structure. This technique is commonly used to produce metal mesh with various apertures and offers good flexibility in the filter mesh.

Characteristics:

High Durability: Woven filter mesh is highly durable and suitable for repeated use.

Limitations: The aperture precision of the weaving process is relatively low, and it is not suitable for manufacturing very fine meshes.

Conclusion

Through photochemical etching, TMN can produce highly precise metal filter mesh, meeting the demands for fine and high-quality products. If you have any inquiries regarding metal filter mesh or the photochemical etching process, please feel free to contact us via phone, WeChat, and WhatsApp at +8613603056883, or email us at lydia.sales1@tmnetch.com. We are dedicated to providing you with support and service.

Read more:

Stainless steel filter mesh: manufacturing process and types

Filter Mesh: a common filtering tool

How to choose the right Air Filter Mesh