What is Stainless Steel Mesh Screen Used For?

Stainless steel mesh screens are used in various settings due to their versatility and durability. Here are some common applications:

Filtration: In industries like water treatment, chemical processing, and food and beverage production, stainless steel mesh screens are used to filter out impurities and particulates.

Security: These screens are utilized in security applications to prevent unauthorized entry or as protective barriers.

Architectural Design: Stainless steel mesh screens are used in modern architectural projects for both functional and aesthetic purposes, such as facades, balustrades, and interior design elements.

Industrial: They are used in sieves, conveyor belts, and other manufacturing equipment due to their strength and resistance to wear and tear.

What is the Difference Between 304 and 316 Stainless Steel Mesh Screen?

304 and 316 are two common grades of stainless steel used for mesh screens. The main differences are:

304 Stainless Steel: This is the most common grade, known for its good corrosion resistance and affordability. It is ideal for general-purpose applications but may not hold up as well in highly corrosive environments.

316 Stainless Steel: This grade contains additional molybdenum, providing extra corrosion resistance, especially against chlorides and harsh chemicals. It is often used in marine environments or in applications where chemical exposure is a concern.

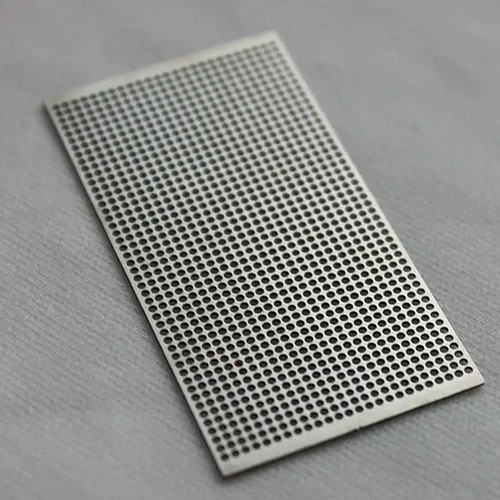

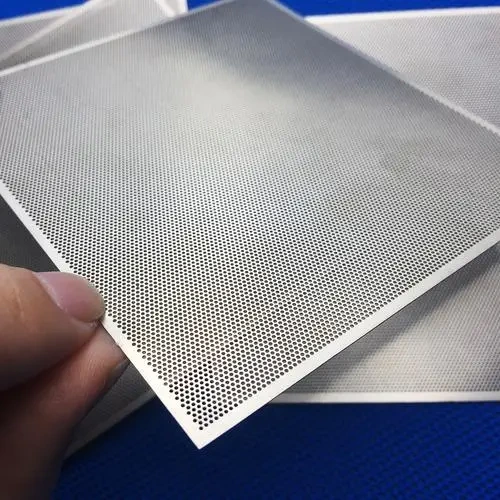

What’s the Thickness of the Raw Materials and the Tolerance Can Be Reached by Photochemical Etching?

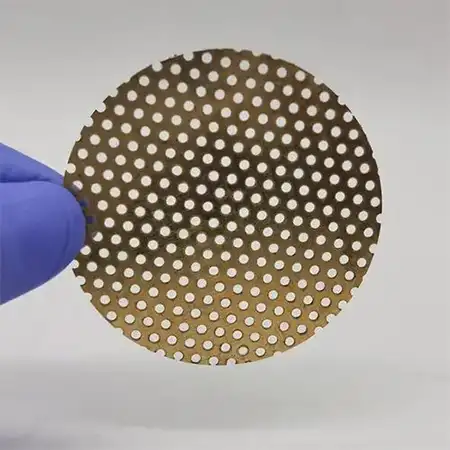

Photochemical etching is a manufacturing process used to create intricate patterns and designs in metal sheets. The typical thickness range for raw materials in this process is:

Thickness: 0.001 inch to 0.078 inch

Tolerance: +/- 0.001 inch

These tight tolerances make photochemical etching a suitable process for creating precise and detailed mesh screens.

What’s the Process for Coating/Plating After Photo Etching Can Be Done?

After the photochemical etching process, stainless steel mesh screens can be coated or plated to improve their properties or appearance. Some common coatings and platings include:

Nickel Plating: Provides corrosion resistance and wear resistance. Typical thickness is 1—10μ.

Tin Plating: Used for solderability and corrosion resistance. Typical thickness is 1—10μ.

Ag Plating (Silver): Offers excellent conductivity and corrosion resistance. Typical thickness is 1—10μ.

Au Plating (Gold): Provides superior corrosion resistance and conductivity. Typical thickness is 1—10μ.

Is Stainless Steel Mesh Screen Strong?

Yes, stainless steel mesh screens are strong and durable, capable of withstanding considerable mechanical stress without deforming or breaking. This makes them ideal for heavy-duty applications where strength is a key requirement.

Is Stainless Steel Mesh Screen Heat Resistant?

Stainless steel mesh screens are heat resistant, withstanding high temperatures without losing structural integrity. This characteristic makes them suitable for applications in high-temperature environments, such as ovens, furnaces, or industrial processes involving heat.

How Long Does Stainless Steel Mesh Screen Last?

Stainless steel mesh screens are highly durable and can last for many years, even in challenging environments. Their corrosion resistance and strength contribute to their longevity, making them a cost-effective choice for long-term applications.

Can You Bend Stainless Steel Mesh Screen?

Stainless steel mesh screens can be bent or formed into different shapes, depending on the thickness and design of the mesh. However, bending should be done carefully to avoid damaging the mesh or affecting its structural integrity. Proper tools and techniques are required to achieve the desired shape without compromising the screen's strength.

Our Team And Factory

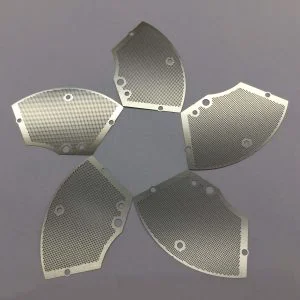

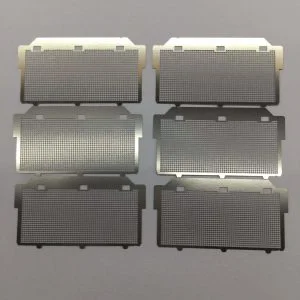

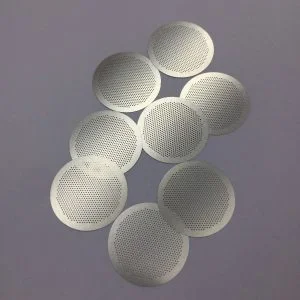

Related Products

Get instant quote