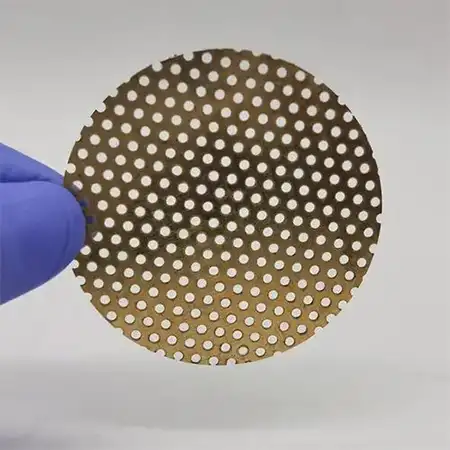

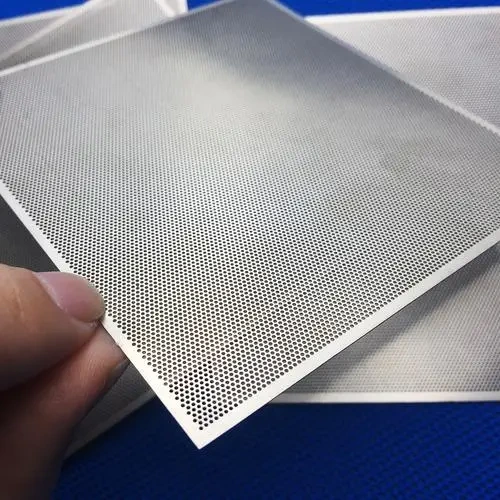

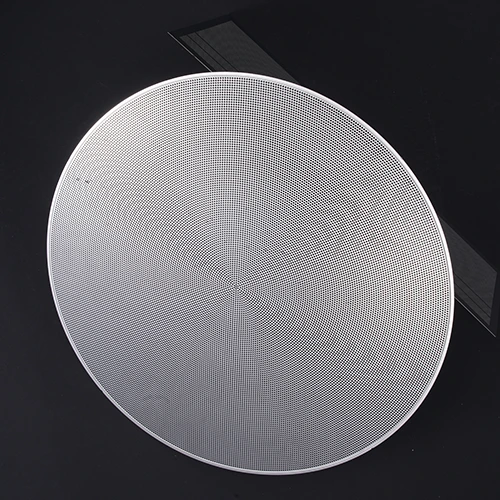

TMN has over ten years of industry experience in custom brass filter mesh manufacturing, primarily utilizing photochemical etching for etching. We can customize different apertures according to user needs, enabling the creation of fine mesh structures for filtering small particles and coarser mesh structures for larger impurities.

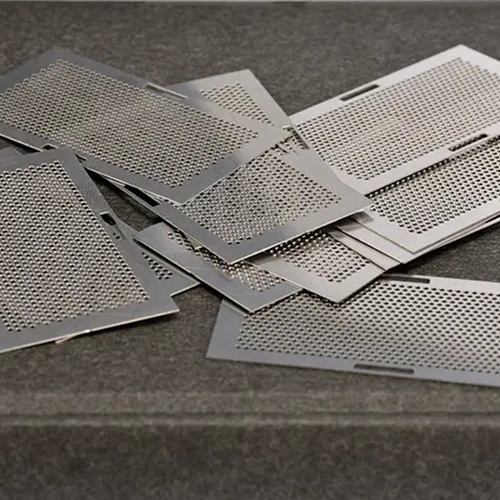

After the filter mesh is etched, we also provide secondary processing to offer you the most comprehensive processing services.

What is a Brass Filter Mesh?

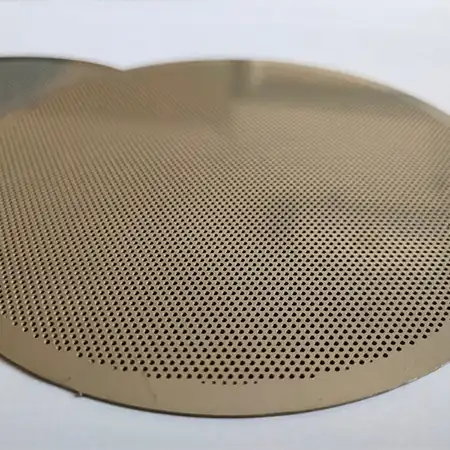

A brass filter mesh is a filtration device made from brass material. Brass is an alloy composed of copper and zinc, known for its excellent corrosion resistance, wear resistance, and good electrical conductivity. Due to the properties of its metal material, brass filter mesh is widely used in industries such as chemical, petroleum, pharmaceutical, food processing, and water treatment. Its unique metallic luster and oxidation resistance allow it to maintain stable performance even in high-temperature and high-pressure environments.

Photochemical etching is a crucial method for manufacturing brass filter mesh. By precisely controlling the exposure time and chemical reactions, intricate mesh structures can be created to meet different particle filtration needs. Brass filter mesh can effectively filter various particles and impurities and is easy to clean and reusable, making it an ideal choice in industrial production.

Brass Filter Mesh Manufacturing Parameters:

Material: Brass, Copper

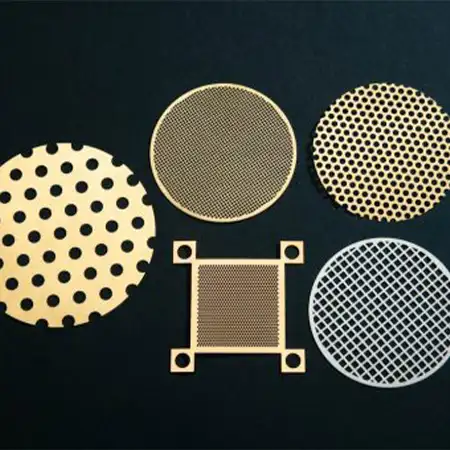

Classification: Filter Disc

Filter Disc Shapes: Circular, Rectangular, Ring, Square, Oval, Star, or Special Shapes

Filter Mesh Hole Shapes: Circular, Square, Oval, Microporous, Honeycomb

Layers: Single Layer, Double Layer, Multi-layer

Processing Technique: Photochemical Etching

Custom Diameter Specifications: Maximum width 1200mm, Minimum width 3.0mm

Custom Mesh Count: Various mesh counts available, such as: 10 mesh, 50 mesh, 100 mesh, 150 mesh, 200 mesh

Custom Thickness: Specifiable filter mesh thickness, such as: 0.01mm, 0.05mm, 0.1mm, 0.2mm

Secondary Processing Available: Polishing, Stamping, Grinding, Color Filling, Electroplating, Passivation

Note: Learn more about TMN's Etching Metal Filter Mesh Manufacturing Capabilities

Why Choose TMN for Customizing Brass Filter Mesh?

Rich Experience: TMN has over ten years of experience in custom brass filter mesh services, primarily using photochemical etching for manufacturing. This ensures that the products are stress-free, burr-free, and highly precise, with tolerances for filter mesh and screens controlled within +/- 0.03mm.

Ample Material Reserves: TMN has a large independent warehouse, storing various raw materials with thicknesses ranging from 0.01mm to 2.0mm. Once we receive the design files, TMN can prepare photo tools and create prototypes within 6 hours. Our products are exported worldwide, and we have extensive experience in arranging delivery and preparing related documents and COC certificates for customs clearance and import inspections.

Comprehensive Secondary Processing Services: In addition to manufacturing high-quality brass filter mesh, we also offer comprehensive secondary processing, including polishing, stamping, grinding, color filling, electroplating, and passivation. This ensures that your products meet all usage requirements in every aspect.

Choosing TMN means you will receive the highest quality brass filter mesh and the most professional service. We are dedicated to providing our customers with the best solutions to meet all your filtration needs.

Note: Learn more about TMN's corporate development and manufacturing capabilities.

Our Team And Factory

What is brass filter mesh used for?

Brass filter mesh is widely used in various industries such as chemical, petroleum, pharmaceutical, food processing, and water treatment. Its applications include filtering fine particles, removing impurities, and protecting equipment by preventing the entry of unwanted debris. The mesh's unique properties make it suitable for use in high-temperature and high-pressure environments, ensuring consistent performance and durability.

What are the benefits of brass filter screen?

The benefits of brass filter screens include:

Corrosion Resistance: Brass is highly resistant to corrosion, making it ideal for use in harsh environments.

Durability: Brass filter screens are known for their longevity and ability to withstand wear and tear.

Precision: The photochemical etching process used in manufacturing allows for precise control of pore size and shape, ensuring high filtering accuracy.

Versatility: They are available in various shapes and sizes, and can be customized to meet specific requirements.

Reusability: Brass filter screens are easy to clean and can be reused multiple times, making them cost-effective.

High Strength: Brass has excellent mechanical properties, providing strength and reliability in demanding applications.

Aesthetic Appeal: The attractive metallic sheen of brass adds to the visual appeal of the equipment where it is used.

Related Products

Get instant quote