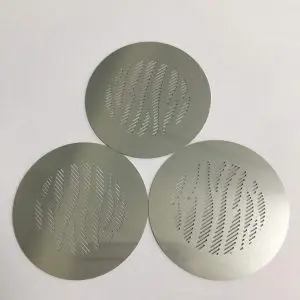

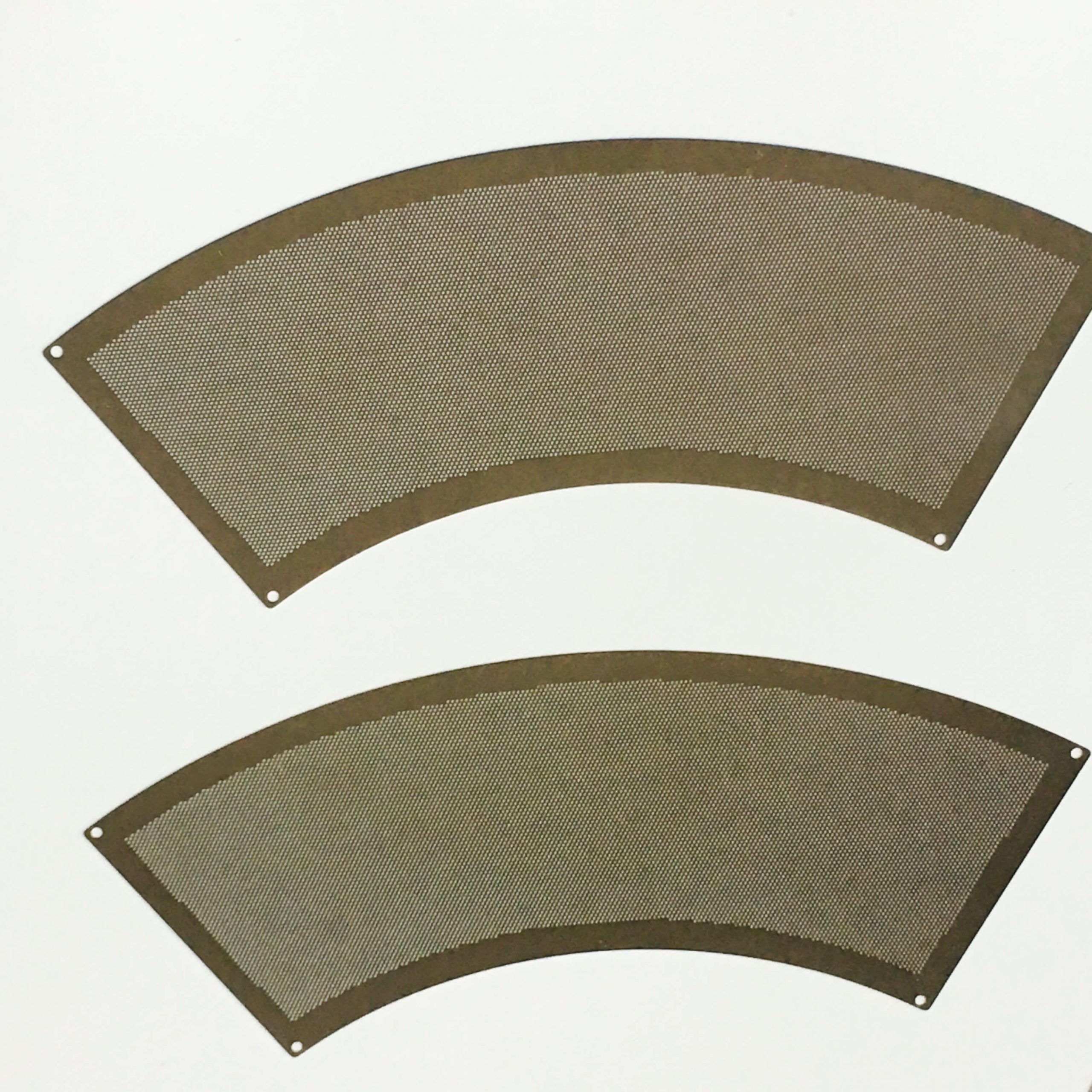

The steel mesh plate mainly uses stainless steel plates. By accurately perforating the stainless steel plates, the desired filter mesh is obtained. It is TMN's most popular custom product, primarily because it perfectly retains the characteristics of stainless steel (such as aesthetics, high mechanical strength, corrosion resistance, and ease of processing). Currently, steel mesh plates have been exported to various countries worldwide, with the main markets being Europe, America, and Southeast Asia.

What is a Steel Mesh Plate?

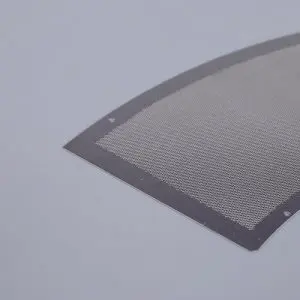

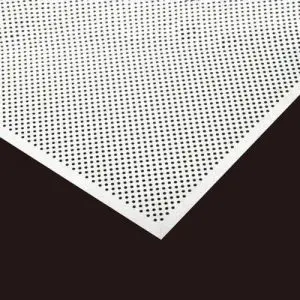

A steel mesh plate is a mesh-structured plate made by processing stainless steel plates. It is mainly used for filtering and screening various substances. Steel mesh plates can be divided into several types based on their use and processing methods, including but not limited to the following:

Stainless Steel Material: Mainly uses models such as 304, 304L, 316, 316L stainless steel. These materials not only have excellent corrosion resistance but also possess high strength and an aesthetically pleasing appearance, making them suitable for various industrial and civilian applications.

Photochemical Etching: This technology uses photosensitive materials and chemical etching solutions to process fine patterns and pore sizes on stainless steel plates, achieving high-precision microporous structures. It is one of the important means in modern high-tech manufacturing.

Steel mesh plates are widely used in petroleum, chemical, food, pharmaceutical, electronic devices, and machinery manufacturing fields, becoming an indispensable important material in various industries.

Manufacturing Parameters of Steel Mesh Plate:

Material: Stainless steel 304, 304L, 316, 316L

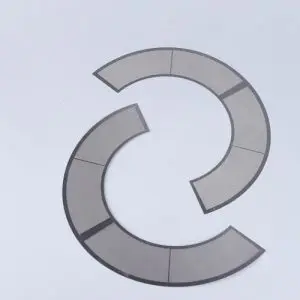

Filter Mesh Shape: Round, square, irregular shapes

Filter Mesh Pore Shape: Round, strip, honeycomb, microporous, etc.

Processing Technology: Photochemical etching

Customizable Size: Diameter from 3.00 to 1200mm

Customizable Mesh Size: 1~100 mesh, 100~200 mesh, 200~400 mesh

Customizable Thickness: Thinnest up to 0.01mm, thickest up to 2.0mm

Secondary Processing Available: Polishing, stamping, grinding, coloring, electroplating, passivation

Note: Learn more about TMN's Etching Metal Filter Mesh Manufacturing Capabilities

Why Choose TMN Custom Steel Mesh Plates?

Founded in 2011, TMN is China's leading custom metal filter mesh manufacturer. Our etched filter meshes and mesh plates have been exported worldwide, with major markets including the United States, the United Kingdom, Germany, Switzerland, Australia, France, Hungary, Israel, Singapore, Vietnam, Malaysia, Thailand, and other countries and regions.

We are both a professional manufacturer and a trading company, capable of providing one-stop services. From consultation and quotation, ordering, manufacturing, quality inspection to shipping, we have dedicated departments and professionals responsible for each stage, ensuring high product quality and customer satisfaction.

Reasons to Choose TMN:

Professional Team: We have experienced engineers and technicians who can provide the best solutions according to customer needs.

Advanced Equipment: We have introduced advanced production equipment and testing instruments to ensure that each batch of products meets international standards.

Strict Quality Inspection: We have a comprehensive quality control system, with dedicated personnel responsible for each process, ensuring stable and reliable product quality.

Excellent Service: We offer comprehensive pre-sales, in-sales, and after-sales services, promptly responding to customer needs and feedback.

Global Market: Our products are popular in Europe, America, Southeast Asia, and other countries and regions, earning the trust and praise of customers.

Choosing TMN means choosing high-quality steel mesh plates and professional service. We look forward to cooperating with you to create a better future together.

Note: Learn more about TMN's corporate development and manufacturing capabilities.

Our Team And Factory

Why Steel Mesh Plates Mainly Use Stainless Steel Plates?

Steel mesh plates primarily use stainless steel plates rather than ordinary steel plates due to the numerous unique advantages of stainless steel, which make it perform exceptionally well in various applications.

Firstly, stainless steel has excellent corrosion resistance, allowing it to maintain good condition in humid, acidic, and alkaline environments without rusting easily, thereby extending its service life.

Secondly, stainless steel has high mechanical strength, enabling it to withstand significant pressure and impact, ensuring the structural stability and durability of steel mesh plates. Additionally, the surface of stainless steel is smooth and aesthetically pleasing, with good processability, allowing for secondary processing such as polishing and electroplating, which enhances the overall appearance and practicality of the product.

Although ordinary steel plates may be more cost-effective in some aspects, they have poorer corrosion resistance and mechanical strength, shorter service life, and are prone to rust, leading to high maintenance costs. Therefore, stainless steel plates become the preferred choice for manufacturing high-quality filter meshes.

Advantages and Features of Photochemical Etching in Steel Mesh Plate Manufacturing

Photochemical etching is a high-precision processing technology that uses photosensitive materials and chemical etching solutions to finely process patterns and apertures on stainless steel plates. This technique offers many unique advantages.

Firstly, photochemical etching can achieve high precision and complex pattern processing, with apertures and shapes that can be flexibly customized according to requirements, meeting the needs of various complex structures and high-precision applications.

Secondly, this process does not impart mechanical stress or thermal effects on the material surface, maintaining the original physical and chemical properties of stainless steel, thus ensuring the high quality of the finished product.

Moreover, photochemical etching has high processing efficiency and is suitable for mass production, which can significantly reduce manufacturing costs. This process also has environmental benefits, as the waste liquid generated during chemical etching can be recycled and treated, reducing environmental pollution.

Related Products

Get instant quote