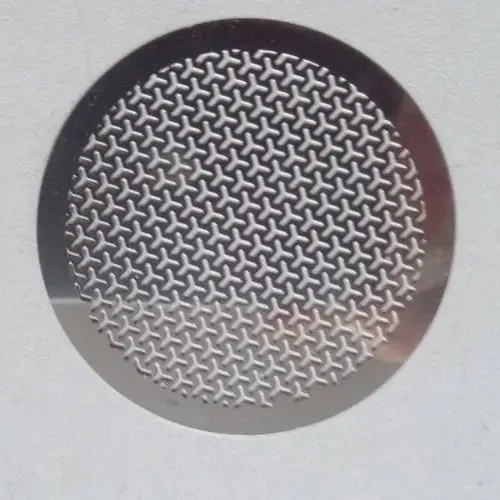

Metal insect screens are an important component in homes and industries, providing effective barriers against pests while allowing airflow and visibility. Etching stainless steel 304 for metal insect screens is a popular method due to its durability, corrosion resistance, and precision in manufacturing. This article explores the uses of metal insect screens, particularly those made with stainless steel 304, and discusses the photochemical etching process used to create them.

What is Etching Stainless Steel 304 for Metal Insect Screen?

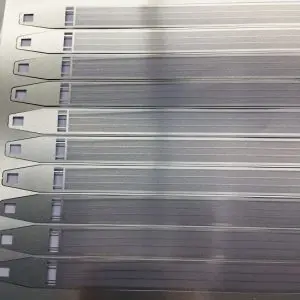

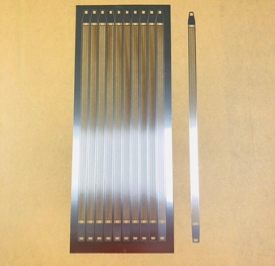

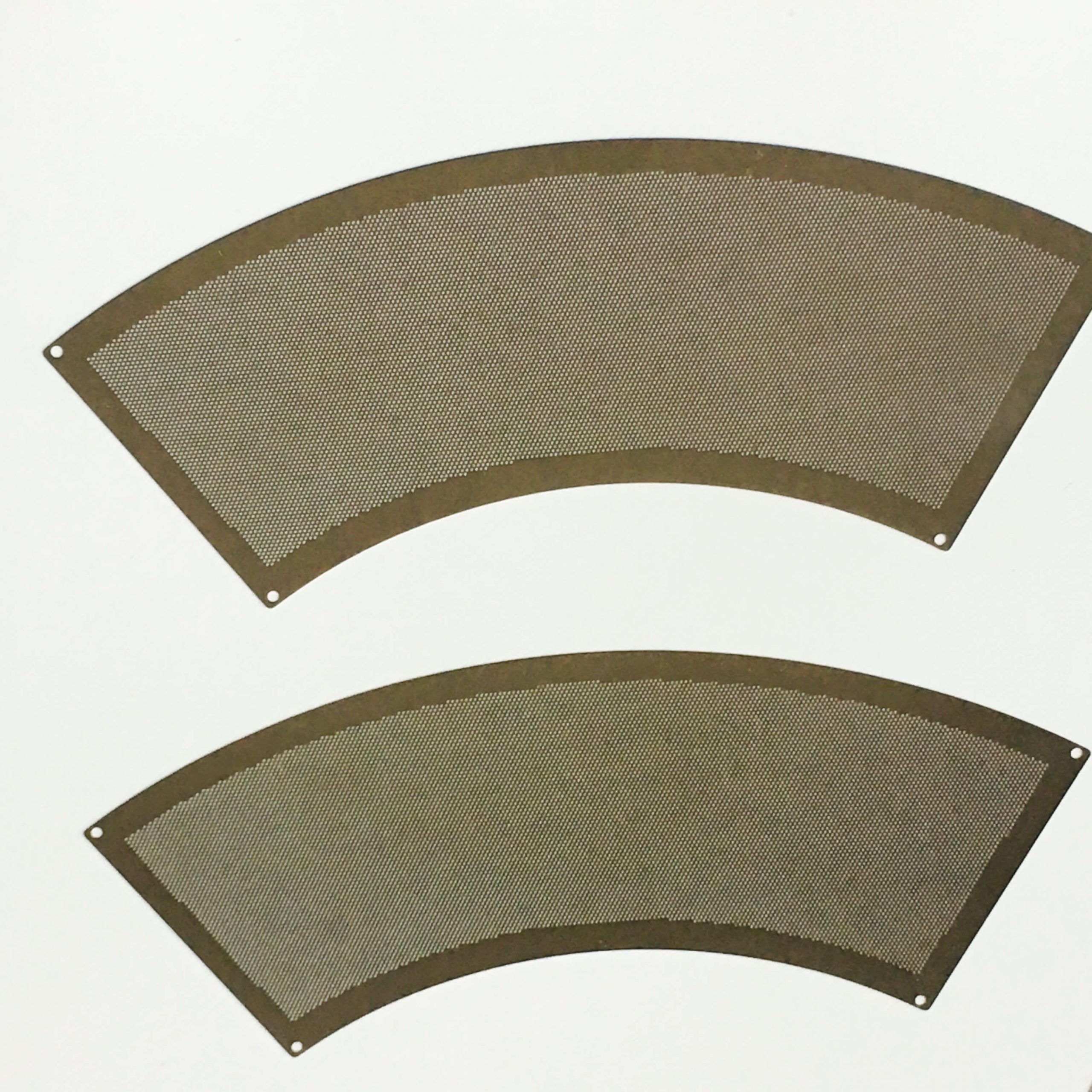

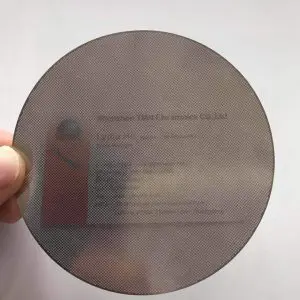

Etching stainless steel 304 is a process used to create precise patterns and fine mesh structures, making it ideal for metal insect screens. The process involves using a chemical solution to remove specific areas of the stainless steel, resulting in a mesh with consistent hole sizes and shapes. This method allows for high precision and flexibility in design, which is essential for creating effective insect screens.

What Household Appliances Can Our 304 Stainless Steel Insect Screen Be Used For?

304 stainless steel is a versatile material that offers excellent corrosion resistance and durability, making it suitable for various household applications. Metal insect screens made from stainless steel 304 can be used in several household appliances, including:

Over-the-Range Microwaves: To prevent insects from entering ventilation areas.

Range/Vent Hoods: To keep insects out of kitchen ventilation systems.

Refrigerators: To prevent insects from accessing air vents and cooling systems.

Dishwashers: To block insects from getting into the dishwasher's air vents.

HVAC Systems: To protect air intakes and prevent insects from entering.

Air Purifiers: To keep insects out while allowing clean air to circulate.

Dryers: To protect dryer vents from insect intrusion.

Vacuums: To keep insects out of air exhausts.

What’s the Thickness of the Raw Materials and the Tolerance Can Be Reached by Photochemical Etching?

The thickness of the raw materials used in photochemical etching for metal insect screens can vary depending on the application's requirements. Typical thickness and tolerance levels for etching stainless steel 304 are:

Thickness: 0.001 inch to 0.078 inch

Tolerance: +/- 0.001 inch

These precise tolerances ensure that the insect screens have consistent mesh patterns, providing effective protection against insects while allowing airflow and visibility.

What’s the Process for Coating/Plating After Photo Etching Can Be Done?

After the photochemical etching process, metal insect screens can undergo additional coating or plating to improve durability and resistance to corrosion. Common coatings and platings used for metal insect screens include:

Nickel Plating: Offers enhanced corrosion resistance and durability, with a typical thickness of 1~10μ.

Tin Plating: Provides additional corrosion resistance, with a similar thickness range.

Silver (Ag) Plating: Known for its excellent conductivity and corrosion resistance, with a typical thickness of 1~10μ.

Gold (Au) Plating: Provides superior corrosion resistance and conductivity, with a typical thickness of 1~10μ.

These coatings/platings are applied based on the specific application requirements and desired properties of the metal insect screens.

What are the Advantages of Producing High Precision & Thin Metal Shims by Photochemical Etching?

Photochemical etching offers several advantages when producing high-precision and thin metal shims, like those used for metal insect screens:

Rapid Prototyping: Prototypes can be completed quickly without the need for additional tooling, typically within 1 to 3 days.

No Scratches and No Burrs: The etching process minimizes physical stress on the material, resulting in smoother edges and no burrs.

Flexible Design Changes: The process allows for easy design modifications, offering flexibility in product development.

High Precision with Small Tolerance: Photochemical etching provides high precision, ensuring consistent mesh patterns with minimal tolerance.

What’s the Mesh Filter for Samples, and How Many Samples Can Be Provided for the First Time?

When creating metal insect screens through photochemical etching, the lead time for samples and the number of samples available for the first time is as follows:

Sample Quantity and Lead Time: Up to 10 sample pieces can be provided for confirmation, with a typical lead time of 4 days for common materials. If special raw materials are required, additional days might be needed to prepare them.

Mass Production Lead Time: For large-scale production, the lead time is generally about 10 days after confirming all details.

In summary, metal insect screens made from etched stainless steel 304 are durable, corrosion-resistant, and suitable for various household appliances. Photochemical etching provides high precision and flexibility in design, allowing for rapid prototyping and consistent mesh patterns. Coating and plating after etching can further enhance the durability and corrosion resistance of these insect screens, ensuring they remain effective and long-lasting.

What is Photo Etching Insect Mesh Made Of?

Photo etching insect mesh is primarily made from stainless steel 304, a widely used grade known for its excellent corrosion resistance, strength, and durability. This material is suitable for outdoor and indoor applications, making it ideal for insect screens that require longevity and resilience against environmental factors.

Related Products

Get instant quote