Metal mesh filter screens are a key component in various audio and filtration applications. This article provides an overview of metal mesh filter screens, their role in microphone pop filters and speaker dust filters, how they're made, and their reusability. We'll also discuss TMN's capabilities in manufacturing these screens and their production timelines.

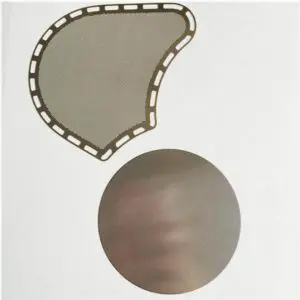

What is a Metal Mesh Filter Screen?

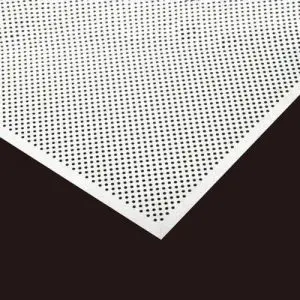

A metal mesh filter screen is a sheet of metal with a grid-like pattern, designed to allow air and sound to pass through while filtering out unwanted particles or debris. These screens are typically made from durable metals like stainless steel or aluminum and are used in a variety of applications, including filtration, ventilation, and audio equipment.

What Does a Metal Mesh Filter Screen Do?

Metal mesh filter screens serve a dual purpose: they allow air and sound to flow freely while filtering out particles like dust, dirt, or debris. In audio equipment, these screens play a crucial role in reducing unwanted noise and protecting sensitive components.

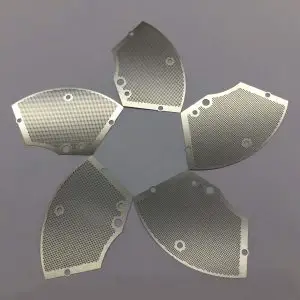

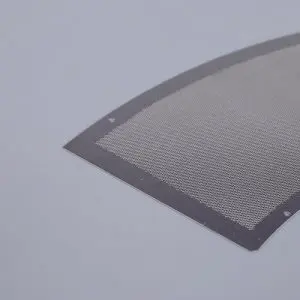

Two common applications for metal mesh filter screens are in microphone pop filters and speaker dust filters:

Microphone Pop Filters: These screens are used in front of microphones to reduce "popping" sounds caused by plosive consonants like 'p' and 'b'. The metal mesh helps to dissipate the force of the air hitting the microphone, resulting in a cleaner recording.

Speaker Dust Filters: These screens are placed over speaker grilles to prevent dust and other contaminants from entering the speaker, thus protecting the internal components and maintaining sound quality.

How Do Metal Pop Filters Work?

Metal pop filters work by dispersing the force of air created by plosive sounds when speaking or singing into a microphone. Plosive sounds can cause distortion or popping noises in recordings, but the fine metal mesh acts as a barrier, allowing sound to pass through while reducing the impact of these bursts of air. Unlike fabric-based pop filters, metal pop filters are more durable, easier to clean, and less likely to degrade over time.

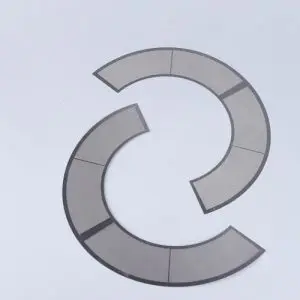

How Are Wire mesh filter screen Made?

Metal mesh filter screens are often manufactured using photochemical etching, a precise and flexible process. Photochemical etching involves coating a metal sheet with a light-sensitive material, exposing it to a patterned light source, and then using a chemical solution to etch away the unexposed areas. This process allows for high precision and flexibility in creating intricate mesh patterns with varying sizes and shapes.

TMN, a leading metal filter manufacturer, has over 10 years of experience in photochemical etching. With a 4,000-square-meter workshop and 100 experienced workers and engineers, TMN has the expertise to produce high-quality metal mesh filter screens for a variety of applications. Their manufacturing capabilities include:

5 Automatic Etching Production Lines: These lines, each 20 meters long, ensure high production capacity and efficiency.

Advanced Equipment: Including 2 automatic cleaning machines, 2 automatic coating machines, and 6 exposure machines.

High Production Capacity: TMN can produce 20,000 sheets per day, each measuring 200x300 mm.

TMN offers 10-piece samples for confirmation, with a typical turnaround time of 4 days for common materials. If special raw materials are required, the preparation time might take a bit longer. For mass production, once all details are confirmed, TMN can complete orders in about 10 days, demonstrating their efficient production process.

Are Metal Filters Reusable?

Yes, metal filters are reusable. Unlike disposable filters, metal mesh filters can be cleaned and reused multiple times, offering a cost-effective and environmentally friendly solution. Metal filters' durability and resistance to wear make them ideal for applications where reusability is desired. They can be cleaned with water and mild detergent or other cleaning solutions, then reused without losing their effectiveness.

Related Products

Get instant quote