A water filtration mesh is a material used to remove particles, impurities, and contaminants from water. By physically separating unwanted elements from water, it ensures that the water becomes cleaner and safer. This article provides detailed information about TMN’s stainless steel water filtration mesh products.

What is Water Filtration Mesh?

Also known as a water filter screen, water filtration mesh is commonly used in various water purification systems to filter out impurities. In households, it can remove sand, rust, bacteria, and other contaminants from tap water, ensuring safe drinking water. In industrial applications, it filters out impurities from process water, protecting equipment and ensuring production quality. In agriculture and aquaculture, it maintains clean water to ensure the health of fish and plants.

Specifications of Water Filtration Mesh

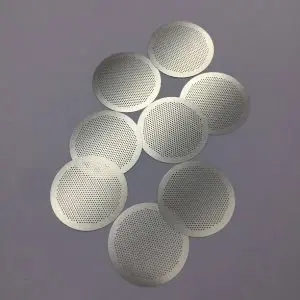

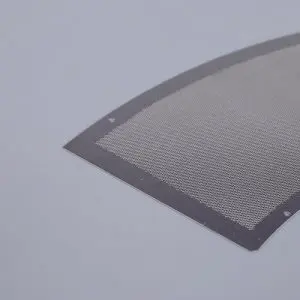

Material: SUS304 stainless steel, SUS 316L stainless steel (customizable)

Thickness: 0.1mm, 0.2mm, 0.3mm (customizable)

Type:Metal mesh filter

Craftsmanship: Photo-etching

Features: Uniform mesh, burr-free, no gaps

Applications of Water Filtration Mesh

The three most common applications include, but are not limited to:

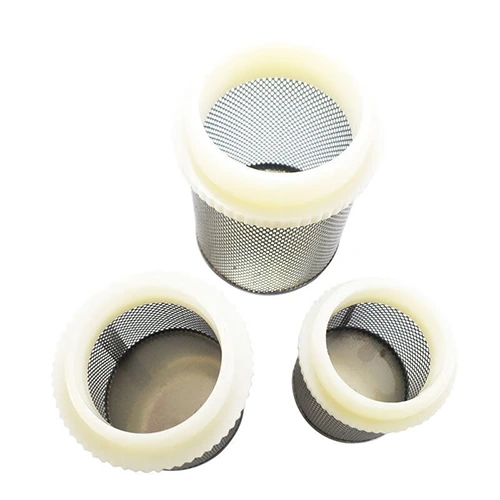

Pre-filters: Installed at the main water inlet to initially screen out larger particles.

Household Water Purifiers: Filters fine particles and microorganisms, enhancing tap water purity.

Reverse Osmosis Filters: Removes almost all dissolved substances, including bacteria, viruses, heavy metals, and salts.

How to Customize Stainless Steel Water Filtration Mesh

To customize a water filtration mesh, simply provide your product design and specifications. Upon receiving the design, TMN can produce a prototype within 6 hours. TMN has a large independent warehouse that can store various materials ranging from 0.01mm to 2.0mm in thickness. With extensive experience exporting metal filtration meshes to countries such as the USA, UK, Canada, South Korea, Germany, the Netherlands, Singapore, Russia, Iran, Israel, Austria, and Australia, TMN is well-equipped to meet your needs.

Our Team And Factory

Why is Water Filtration Mesh So Important?

Based on the above product introduction, the water filter is crucial for the following reasons:

Health and Safety: They ensure that drinking water is free from harmful contaminants, protecting public health.

Industrial Efficiency:They maintain the quality of process water, which is crucial for the proper functioning of industrial equipment and the quality of the end products.

Environmental Protection:They help in treating water for reuse, reducing the environmental impact of industrial and agricultural activities.

Water filtration meshes are essential components in ensuring the purity and safety of water across various applications. TMN’s high-quality stainless steel filtration meshes offer reliability and precision, making them an excellent choice for both standard and customized water filtration needs.

Related Products

Why Partner with us?

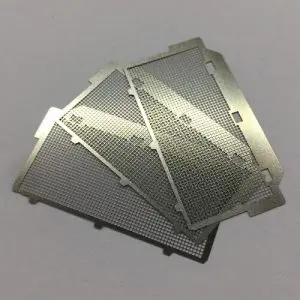

Photo Chemical etching is a precision process of using a strong chemical solution to create the desired designs on the flat sheet of metal.

The main raw materials that TMN has etched are stainless steel 300 series ,brass ,copper ,aluminum ,titanium ,kovar ,nickel with thickness range from 0.01mm to 3.0mm ,the main products of TMN are below ,

- Ultra-thin and high precisioncustomized metal shims/ washers /gaskets /springs /apertures.

- Fuel cell bipolar plates & flow field plates with titanium and stainless steel 316L,the dimension large can be 800mm width and 1500mm length.

- EMI / RF shielding parts and covers with nickel silver material .

- Filter meshesand screens with micro holes and tolerance controlled within +/- 0.03mm.

- Lead frame with copper and brassand do gold & silver plating.

- Optical maskwith micro slit as 0.02mm thin.

- Shadow mask with custmized structures.

- Encoder discs with hundreds of grooves .

- Ophthalmic surgical knife

- Model puzzle parts for ship ,airplane ,house ,tank ,car ,castle ,building with stainless steel and brass.

TMN etched parts and sheets have been exported to different countries all over the world,the main marketings are United States ,England ,Germany ,Switzerland ,Austra ,France,Hungery,Isreal,Singapore,Vietnam,Malaysia,Thailand and so on.TMN has enough experiences to arrange delivery and prepare relative documents and COC certificates for Customs clearance and import checking issue.

Why Partner With TMN Etch

Get instant quote