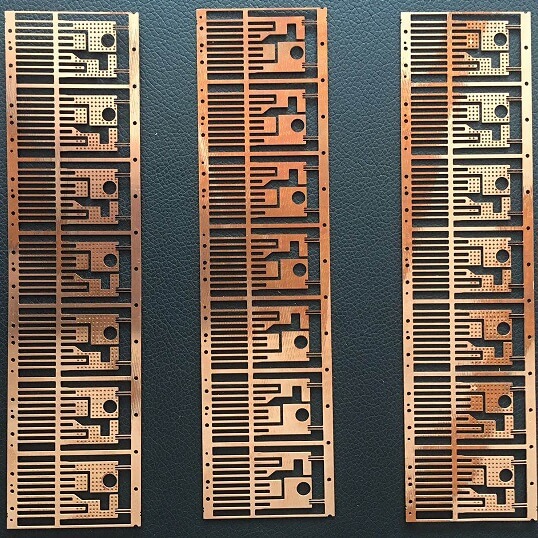

custom micro lead frame

1. What’s the production capacity of TMN for Lead Frame Parts?

· TMN has more than 10 years experience of OEM & ODM the shielding parts with 4000 square meters workshop and 100 experienced workers and engineers

· 5 automatic etching production lines with 20 meters long.

· 2 automatic cleaning equipment, 6 stamping machines.

· The production capacity of TMN is 300000pcs.

· Enough experience of export shielding parts to the USA, UK, Canada, Korea, Germany, Netherlands, Singapore, Russia, Iran, Israel, Austria, Australia and so on.

· Designed all Lead Frames for different industries, such as Aerospace, Automotive, Industrial, Marine, Medical, Military, Electronic, etc.

2. What are the main raw materials of Lead Frame covers and clips?

· Stainless Steel Alloys, Copper Alloys, Brass Alloys, Aluminum Alloys, Nickel Silver, Some other special requested metal materials.

3. What’s the thickness of the raw materials and the tolerance can be reached by photochemical etching?

· Thickness: 0.001 inch to 0.078 inch

· Tolerance : +/- 0.001inch

4. What’s the process for coating/plating after photo etching can be done?

· Nickel plating 1~10μ

· Tin plating 1~10μ

· Ag plating 1~10μ

· Au plating 1~10μ

5. What are the advantages of TMN manufacturing plants?

· Rapid for prototypes without any tools (1~3 days can be finished the prototypes)

· No scratches and no burrs

· Designs can be changed flexibly

· High precision with a small tolerance

6. What’s the lead time for samples, and how many samples can be provided for the first time?

· 10PCS samples can be provided for confirmation and 4 days as the lead time for common materials, if the raw material is special, it will take some days to prepare raw materials.

· For mass production, it is about 10 days after confirming all details.

7. If you want to inquiry TMN, What should you do?

Just need to send an email to lydia.sales1@tmnetch.comwith drawings at the format of DXF, DWG, PDF, 7*24 hours available.

Our Team And Factory

Get instant quote