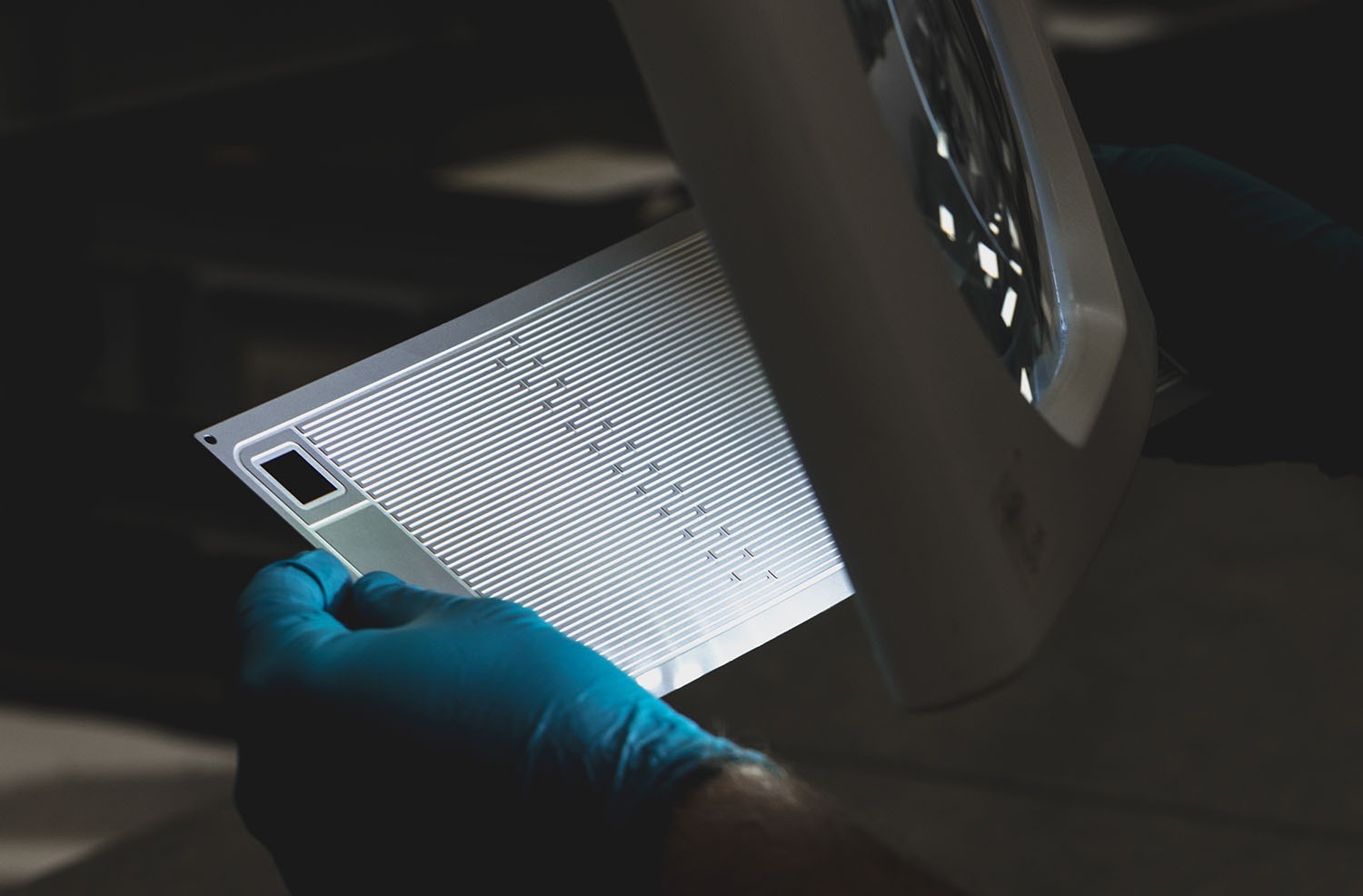

Titanium Bipolar Plates for Fuel cell

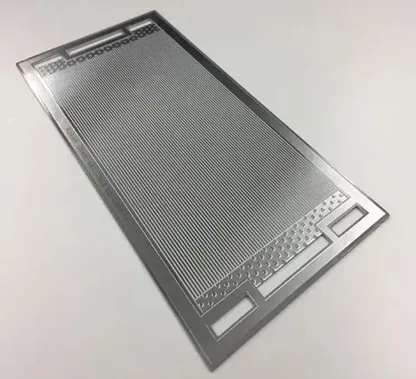

TMN Photochemical Etching Factory is experienced in designing titanium bipolar plates with etched channels and solid metal separator plates. These vary from simple carbon supports to the more complex configurations where units are stacked serially to optimise the power voltage, which will require proper collation and collecting electrodes for efficient current collection, conduction, and output. Also, integrated gas pathways between the cell units work seamlessly.

Designed to improve performance, efficiency, and stability for fuel cells, our titanium bipolar plates provide superior quality for various battery applications.

Specification of Titanium Bipolar Plates

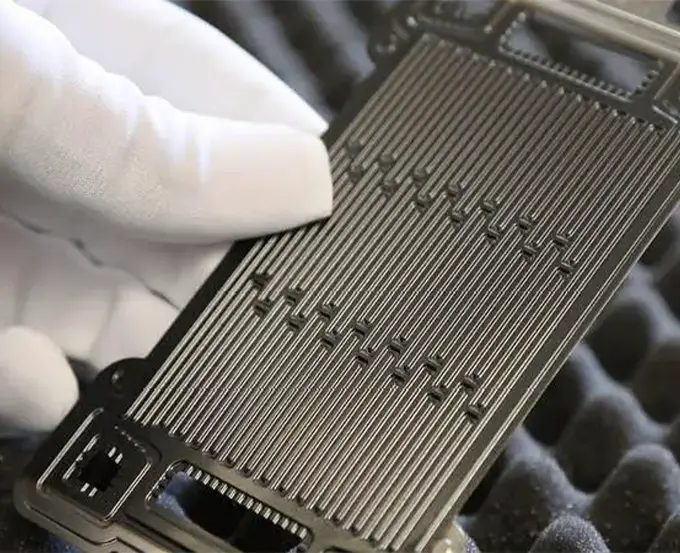

- Material: High-purity titanium (≥99.5%).

- Thickness: 0.3 mm to 1.0 mm.

- Channel Depth: ±0.03 mm precision.

- Surface Roughness: ≤ Ra 0.8 μm.

- Corrosion Resistance: Excellent, suitable for harsh environments.

- Electrical Conductivity: Optimized for efficient current conduction.

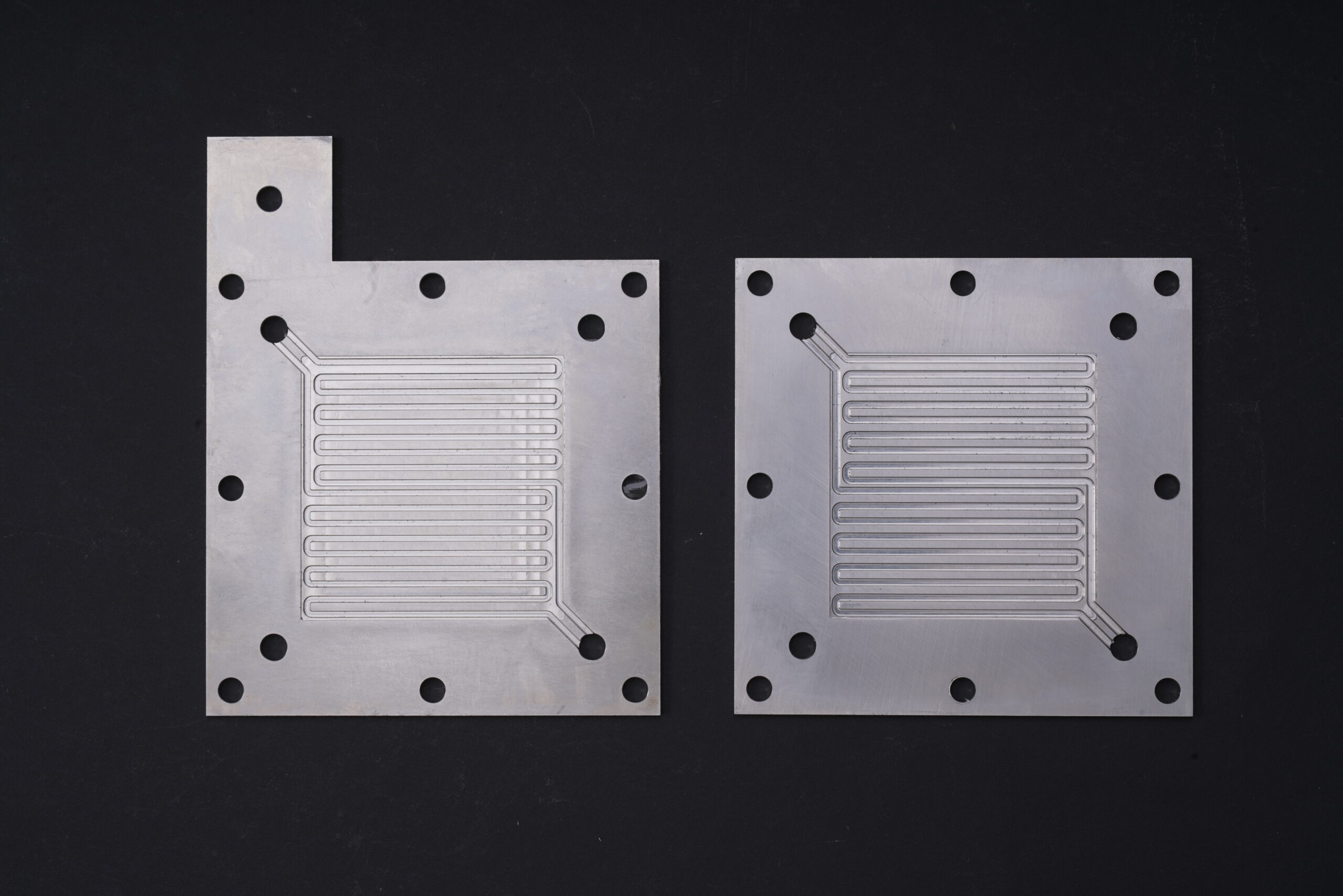

- Gas Flow Design: Smooth, precise channels for uniform distribution.

- Customizability: Designs tailored to client specifications.

- Production Method: Advanced photochemical etching for high accuracy.

Functions Of Bipolar Plates

Titanium bipolar plates serve as the pathway for the flow of current in the fuel cell, ensuring efficient collection and conduction of the current generated by the hydrogen-oxygen reaction to support the normal operation of the cell.

Gas Flow Channels: The bipolar plates are made from titanium to ensure that the gas flow would separate the hydrogen and oxygen two to the cell anode and cathode to facilitate electrochemical responses.

Gas Mixing Prevention: Titanium bipolar plates are constructed to offer a barrier between the cathode and anode regions, thus minimising the intermingling of hydrogen and oxygen, which would cause a variety of unfavourable reactions and energy loss for the desired effective operation of the cell.

Structural Framework: The titanium bipolar plates are used as a rigid structure to support the different components and provide a secure means of fastening other parts to ensure stability of the entire system.

Why TMN etching is best for Bipolar plates?

Choosing TMN Photochemical etching for titanium bipolar plates offers several key advantages:

Precision and Accuracy: Our method of photochemical etching offers a high degree of accuracy and uniformity of channel formation, which is necessary for current-carrying and gaseous transport in fuel cells.

Custom Design Flexibility: TMN can control the density and size of etched patterns according to the need of certain application areas in order to achieve the maximum level of operation efficacy for batteries and fuel cells of different types.

Superior Corrosion Resistance: Titanium has great corrosion resistance feature, and our etching application slightly affects the corrosion resistance feature on the titanium plates making them have long durability where there is; harsh environment.

Cost-Effective Production: Significantly, photochemical etching is a low-cost manufacturing technology for intricate shapes, cutting down on the costs of fabrication compared to the aggressive methods.

High-Quality Material: High purity level greater or equal to 99.5% of titanium is utilized and it is ensured that high conductivity, strength and stability is established in the developed bipolar plates.

Scalable for Large Production: TMN’s photochemical etching services are at an advanced level and the company handles production on behalf of clients, small and big hence suitable for any sized undertaking.

Environmental Sustainability: Another advantage of our manufacturing method is that it has lower physical resource consumption, thereby reducing landfill and destruction of materials, energy wastage, and the emission of greenhouse gases into the atmosphere.

When opting for TMN Photochemical Etching, you obtain the solution that meets the technical needs of fuel cell and battery industries.

Send us a message

Whenever it is OK during working time, welcome to send an email to lydia.sales1@tmnetch.com in advance, we will pick up you from Shenzhen, Guangzhou or HK airport.