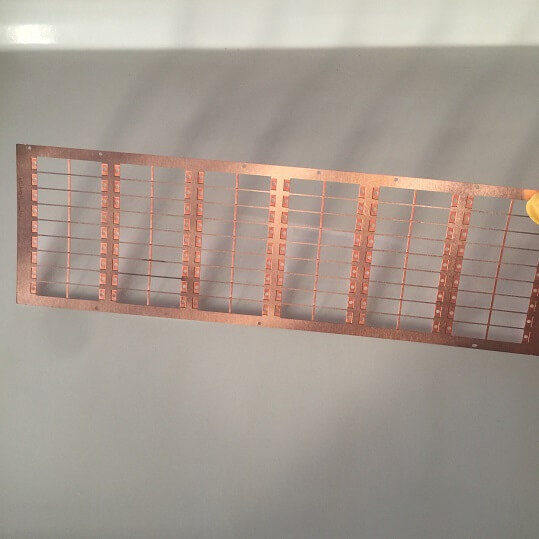

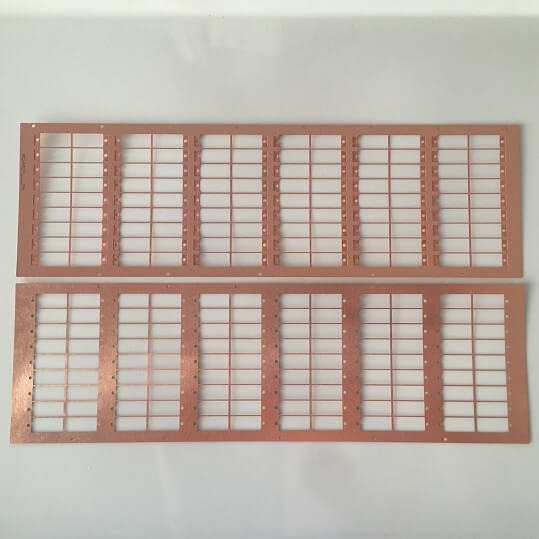

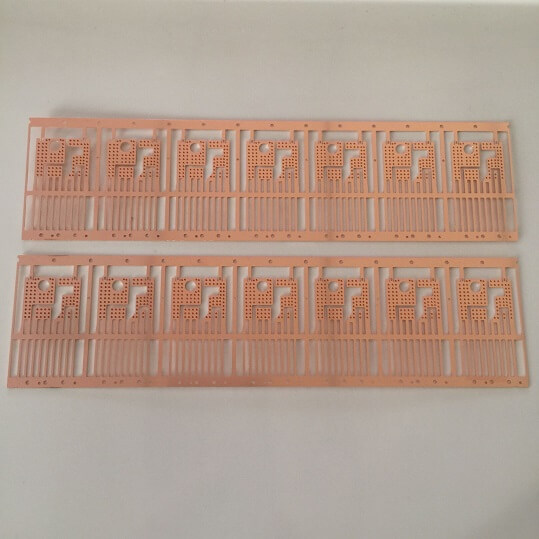

Custom tin and nickel plated lead frame

At TMN Metal Parts Fabrications, we specialize in producing high-quality tin and nickel plated lead frames that meet the stringent demands of various industries, including electronics, automotive, and telecommunications.

Our advanced fabrication processes and commitment to excellence ensure that each lead frame delivers optimal performance and durability.

TMN has more than 10 years experience of OEM & ODM the shielding parts with 4000 square meters workshop and 100 experienced workers and engineers

· 5 automatic etching production lines with 20 meters long.

· 2 automatic cleaning equipment, 6 stamping machines.

· The production capacity of TMN is 300000pcs.

· Enough experience of export shielding parts to the USA, UK, Canada, Korea, Germany, Netherlands, Singapore, Russia, Iran, Israel, Austria, Australia and so on.

· Designed all Lead Frames for different industries, such as Aerospace, Automotive, Industrial, Marine, Medical, Military, Electronic, etc.

What Are Lead Frames?

Lead frames are critical components in semiconductor devices. They act as the bridge between the internal circuitry of a chip and the external leads, enabling seamless connectivity. The choice of materials and plating plays a significant role in ensuring reliability, conductivity, and protection against environmental factors.

Why Choose Nickel Plated Lead Frames?

Nickel plating offers several advantages, making it an ideal choice for lead frames:

- Corrosion Resistance: Nickel plating provides a robust barrier against oxidation and corrosion, ensuring the lead frames maintain their integrity over time.

- Enhanced Electrical Conductivity: The uniform plating layer improves conductivity, essential for high-performance electronic devices.

- Durability: Nickel plated lead frames offer excellent wear resistance, making them suitable for high-stress applications.

- Solderability: The plating process enhances the frames’ solderability, ensuring strong and reliable connections.

Tin Plating for Lead Frames

In addition to nickel plating, we offer tin plating options to cater to diverse application needs. Tin plating ensures:

- Cost-Effectiveness: Tin is a more economical option while still providing good conductivity and corrosion resistance.

- Eco-Friendliness: Our tin plating process adheres to environmentally friendly standards.

- Wide Compatibility: Tin plated lead frames are compatible with a variety of electronic applications.

Our Fabrication Process

- Material Selection: We use high-grade base materials to ensure strength and stability.

- Precision Stamping: Our state-of-the-art equipment delivers intricate designs with unmatched accuracy.

- Plating: We apply nickel or tin plating using advanced techniques to achieve uniform thickness and superior quality.

- Inspection: Every lead frame undergoes rigorous testing to meet industry standards and client specifications.

Applications of Nickel Plated Lead Frames

Our nickel plated lead frames are widely used in:

- Integrated Circuits (ICs)

- Sensors and Transducers

- Power Modules

- LED Lighting Systems

- Automotive Electronics

Why TMN Metal Parts Fabrications?

- Expertise: Decades of experience in metal parts fabrication.

- Customization: Tailored solutions to meet specific requirements.

- Quality Assurance: Stringent quality control measures at every stage.

- Sustainability: Commitment to eco-friendly practices and compliance with global standards.

When you choose TMN Metal Parts Fabrications for your tin and nickel plated lead frames, you’re investing in precision, reliability, and performance. Contact us today to learn how we can support your next project.

FAQ about Tin and Nickel Plated Lead frames

1. What’s the production capacity of TMN for Lead Frame Parts?

· TMN has more than 10 years experience of OEM & ODM the shielding parts with 4000 square meters workshop and 100 experienced workers and engineers

· 5 automatic etching production lines with 20 meters long.

· 2 automatic cleaning equipment, 6 stamping machines.

· The production capacity of TMN is 300000pcs.

· Enough experience of export shielding parts to the USA, UK, Canada, Korea, Germany, Netherlands, Singapore, Russia, Iran, Israel, Austria, Australia and so on.

· Designed all Lead Frames for different industries, such as Aerospace, Automotive, Industrial, Marine, Medical, Military, Electronic, etc.

2. What are the main raw materials of Lead Frame covers and clips?

· Stainless Steel Alloys, Copper Alloys, Brass Alloys, Aluminum Alloys, Nickel Silver, Some other special requested metal materials.

3. What’s the thickness of the raw materials and the tolerance can be reached by photochemical etching?

· Thickness: 0.001 inch to 0.078 inch

· Tolerance : +/- 0.001inch

4. What’s the process for coating/plating after photo etching can be done?

· Nickel plating 1~10μ

· Tin plating 1~10μ

· Ag plating 1~10μ

· Au plating 1~10μ

5. What are the advantages of TMN manufacturing plants?

· Rapid for prototypes without any tools (1~3 days can be finished the prototypes)

· No scratches and no burrs

· Designs can be changed flexibly

· High precision with a small tolerance

6. What’s the lead time for samples, and how many samples can be provided for the first time?

· 10PCS samples can be provided for confirmation and 4 days as the lead time for common materials, if the raw material is special, it will take some days to prepare raw materials.

· For mass production, it is about 10 days after confirming all details.

7. If you want to inquiry TMN, What should you do?

Just need to send an email to lydia.sales1@tmnetch.com with drawings at the format of DXF, DWG, PDF, 7*24 hours available.

Our Team And Factory

Get instant quote