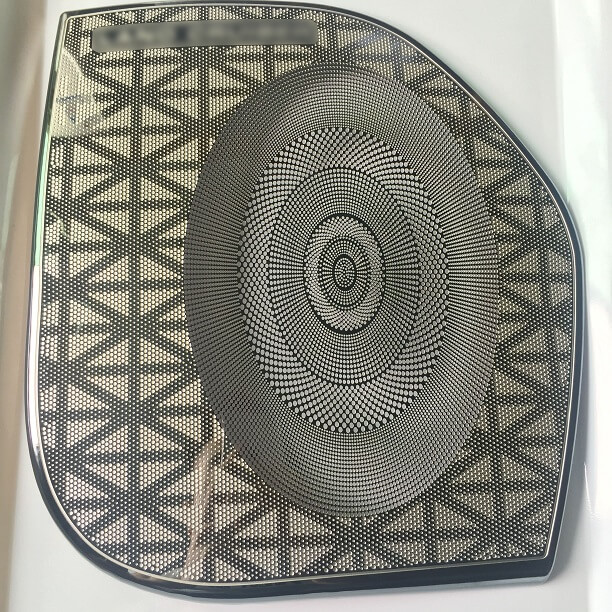

This metal speaker grill is a custom product by TMN, specially designed for front car speakers. Manufactured using advanced photochemical etching technology, each product ensures exceptional precision and superior aesthetics. Whether you are a car manufacturer or a car modification shop, we can meet your bulk customization needs (including small batches) and ensure that every product exceeds your expectations.

What is a Metal Speaker Grill?

A metal speaker grill is a mesh cover used to protect the speaker unit. It not only effectively prevents external objects from damaging the speaker unit but also enhances the aesthetic appeal of the sound system. Compared to other materials, metal speaker grills offer higher strength and durability while maintaining excellent sound quality.

Custom Specifications for Metal Speaker Grills

Customizable Materials: TMN offers 300 series stainless steel, aluminum alloys, and other metal materials.

Customizable Shapes: Round, rectangular, and irregular shapes.

Customizable Thickness: TMN provides metal material thicknesses ranging from 0.03mm to 3.0mm.

Customizable Sizes: 4 inches, 8 inches, 10 inches, and more sizes.

Processing Technology: Photochemical etching.

Secondary Processing: Coating, polishing, cutting, welding.

Note: Learn more about TMN's capabilities in customizing metal speaker grill covers

Why Choose TMN for Custom Metal Speaker Grills

TMN is a factory that specializes in providing customized services with an experienced foreign trade team that can offer integrated customization services. TMN has accumulated rich experience in custom metal speaker grills, not only for car audio but also for home audio, professional audio equipment, and various application scenarios. By choosing TMN, you will receive:

1. A professional design team to ensure each custom product meets the specific needs of the customer.

2. High-quality materials to guarantee the durability and aesthetics of the product.

3. Comprehensive after-sales service to ensure a worry-free user experience.

Note: Learn more about TMN's corporate development and manufacturing capabilities.

Our Team And Factory

TMN Custom Metal Speaker Grill Process

1. Requirement Analysis: The TMN team communicates in detail with the client to understand their specific requirements for the metal speaker grill, including size, shape, material, and mesh pattern.

2. Drawing Confirmation: After receiving the client’s CAD drawings, the final confirmation is made based on the requirements to ensure that the manufactured product meets the specifications.

3. Sample Production: Samples are made according to the CAD drawings (using photochemical etching technology for production).

4. Client Confirmation: 1-2 prototype samples are sent to the client for confirmation to ensure the samples fully meet the client’s expectations.

5. Mass Production: After the client confirms the samples, mass production begins. TMN has five 39-meter fully automated photochemical etching production lines and a strict quality control system to ensure that each product meets high standards.

6. Secondary Processing: Based on the client’s requirements, decisions are made on whether to perform surface treatments such as coating, electroplating, etc., to enhance corrosion resistance and aesthetics.

7. Quality Inspection: Each batch of products undergoes strict quality inspection before leaving the factory to ensure there are no defects.

8. Packaging and Shipping: Finally, the inspected and qualified products are professionally packaged and shipped on time to the client’s specified location.

By choosing TMN to customize your metal speaker grills, you will enjoy professional service and high-quality products, making your audio equipment even more outstanding.

Why Use Photochemical Etching to Customize Metal Speaker Grills

High Precision: Photochemical etching achieves extremely high precision, suitable for manufacturing complex patterns and fine structures.

Low Cost: Compared to traditional processing methods, it does not require mold costs, making it cost-effective for production batches and complex designs.

High Flexibility: Photochemical etching is suitable for various metal materials and can be customized according to your needs.

Quick Production: The time from design to finished product is short, allowing for a rapid response to market demands.

Get instant quote