Metal Washers: Types, Materials, Purpose & Industrial Uses

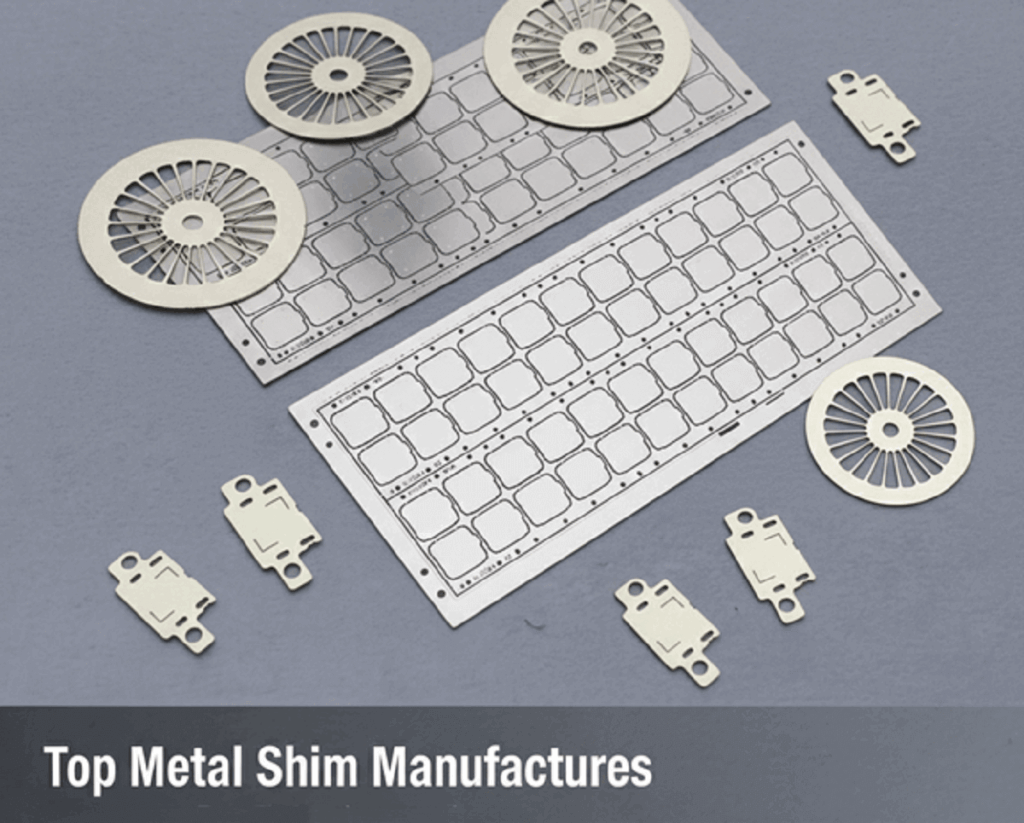

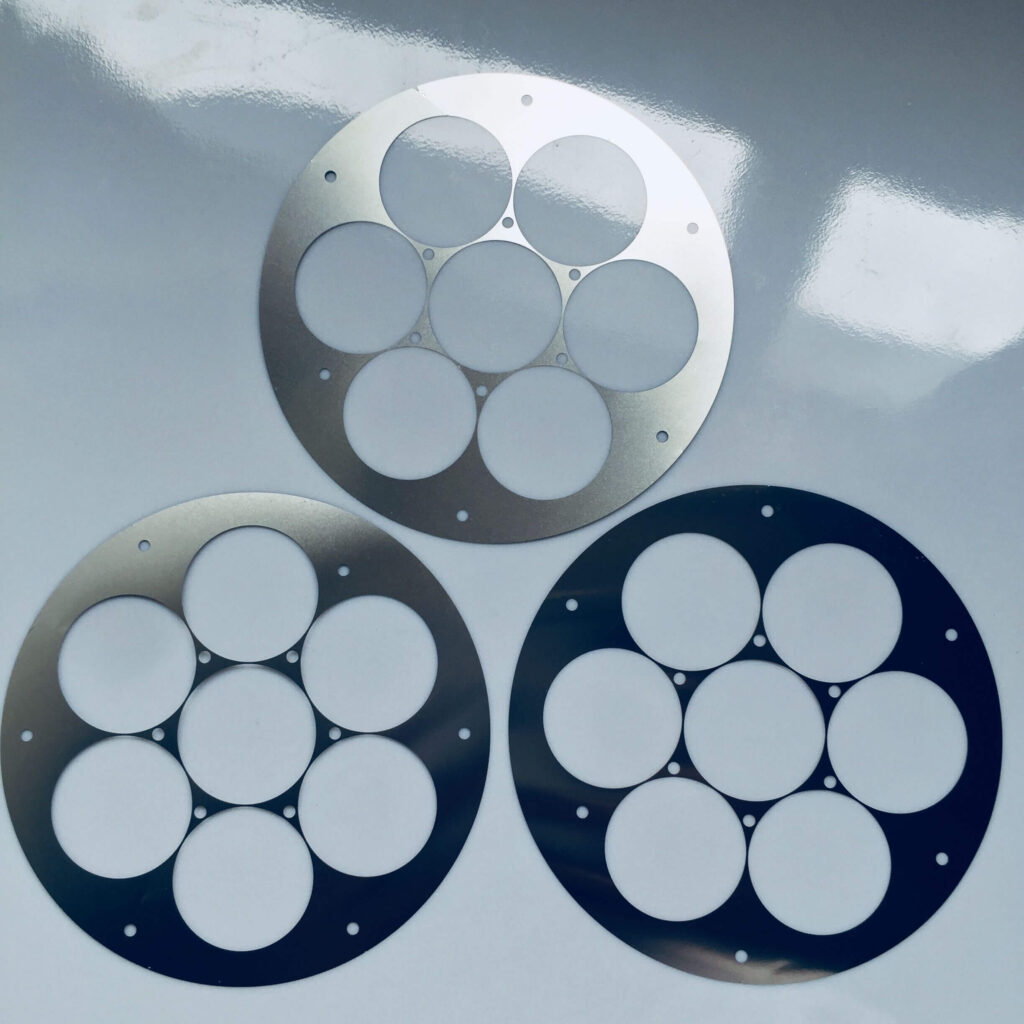

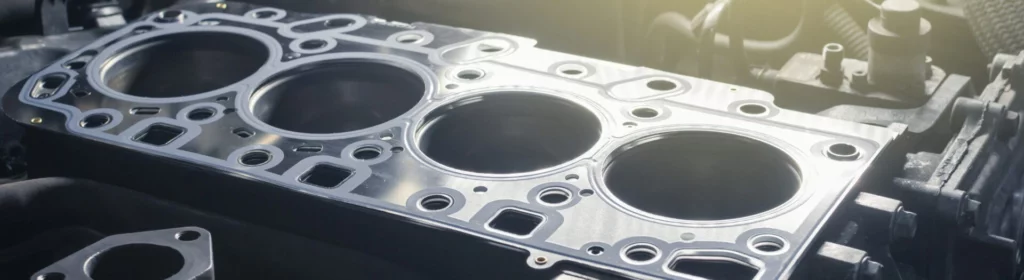

Metal washers are used across industries on a day-to-day basis to add stability, distribute loads, and align. Using appropriate metal washers can help prevent breakdowns and prolong equipment life when the machinery vibrates, transports critical loads, or is required to be precisely positioned. TMNetch supports these needs by offering precision‑etched components used in custom metal

Metal Washers: Types, Materials, Purpose & Industrial Uses Read More »