In the domain of battery technology, especially rechargeable systems, battery’s efficiency, and performance dictates the consideration of every stage in its manufacture. One such crucial, but most times under considered process is cathode drying. If not properly optimized, the process of cathode drying may account for as much as 40% of the total manufacturing costs in terms of energy usage within a battery’s life cycle. This paper will propose solutions to the process that will allow both energy conservation and good battery performance.

Awareness of Cathode Drying Process

What is cathode drying?

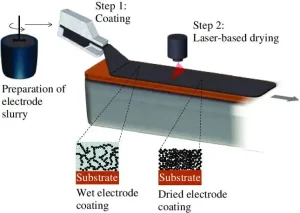

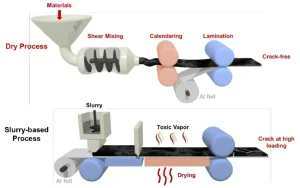

Cathode drying is one of the more important steps in the production of a lithium-ion battery. During this step, if there are for instance any solvents used in the cathode coating, they have to be completely evaporated and removed to prepare the electrode for the battery cell. This lends itself to ensuring that the conductive dry powder polymer cathode, which facilitates the ion movement of lithium, is dried enough to enhance its sounding conductor stuffing confinement.

Why is it important in battery manufacturing?

It has already been emphasized that the drying step modifies the quality (in particular, the handles of the battery) and lifespan of the system. If a battery is dried improperly, then defects such as unreliable and rough drying leading to uneven coatings may affect the energy density, performance, and even safety of the battery.

Energy Consumption in Cathode Drying

The efficient energy consumption is very crucial in the production of batteries because it is cost effective. Away from that the cathode drying process takes up a lot of energy in battery production. There are studies undertaken that show that it could attribute up to 40% of the energy used in the entire battery production. The challenge is to reduce this energy burden without compromising the quality of the electrodes.

Challenges in Optimizing Cathode Drying

There are several reasons that compel one to seek an improvement in the process of cathodes drying optimization. Here are some of the common challenges:

Inadequate/effective drying:

Some portions of the cathode could dry faster than others because of inadequate temperatures or airflow which leads to quality problems.

Energy wastage:

To save on time, high amounts of energy are used on certain occasions especially in attempts to hasten the drying time or in poor addressing process design.

Over drying:

Over drying could cause corrosion of some materials of the cathode further reducing maximum efficiency of the battery.

Factors Affecting Cathode Drying

To be able to enhance the cathode drying procedure, it is necessary to explain the factors that are vital in this process.

Temperature Control

It is very important to maintain the right temperature during the drying period. If there is a lot of heat then such materials tend to be damaged. If there is not enough heat, dry cleaning can take place for a long time which is more absorbing.

Humidity Levels

The ambient humidity can greatly affect the drying process. Should the air imply excessive moisture, the evaporation process will be prolonged thus raising energy utilization. On the other hand, dry air can maximize the evaporation process but may lead to overdrying.

Airflow Management

Airflow assists in taking away the evaporated solvent that is on the surface of cathodes. In situations where airflow management is not properly followed, the drying process may be non-uniform therefore leading to poor electrode activity.

Coating Thickness

The amount of electrode coating has a significant impact on the time taken to dry. The colleague applied more cases hence always resulted in elongation of the drying times thus controlling the standard of the coating is critical to efficient drying.

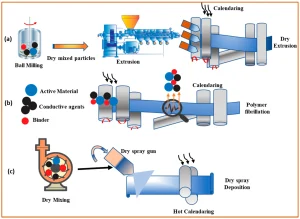

Techniques to Optimize Cathode Drying

Several techniques can be used to enhance the cathode drying process and in the same manner decrease the energy used.

Improved Temperature Monitoring

Purchasing more efficient temperature measuring devices helps regulate the thermal range of the drying stage and minimizes risk of over and insufficient heating. Better management of the temperature during the operation may improve energy efficiency of the system and quality of the electrodes.

Use of Advanced Drying Technologies

New technologies such as infrared drying or microwave drying assist. Suggest that identifiable energy such wavelike or microwave rays assist in eliminating the need for more energy for drying the cathodes.

Mechanical Ventilation Systems

Improving airflow systems can lead to significant advances in cathode drying process efficiency of energy consumption. It is possible for producers to evenly dry the drying chamber by balancing the air flow within the drying chamber thus avoiding the drying imbalance and energy wasteage.

Machine Learning in Practice

Within the given time frame and other conditions such as humidity and temperature, machine learning tools are able to provide recommendations for the drying times. By automating this process, machine learning implements changes that will reduce energy consumption while increasing productivity.

Contact Lydia.sales1@tmnetch.com or visit our Facebook and LinkedIn page for further information.

Fuel Cells: Performance Testing Methods for Common Electrocatalysts