What is PEMFC?

PEMFC stands for proton exchange membrane fuel cell, a cleantech product that produces electricity by combining hydrogen and oxygen. The byproduct formed is water only—that’s right—just water! It is more or less like a battery that goes on as long as it is fed with fuel. Lets find out PEMFC Low-Temperature Environment Application in this article.

Increase Popularity in the Modern World of PEMFC

Whether electric cars or cell towers in the middle of nowhere, PEMFCs are going up in full force. As the push for clean energy sources occurs on the international level, these fuel cells are gaining a lot more focus. But when it comes to working in cold climates, some really cold challenges await them.

Applications of PEMFC Technology

Fixed Power Stations

Being mainly applied in stationary applications, it is applied for power generation in homes, structures, and even industries. They’re reliable, they are cleaned, and can be run for an extended period without breakdown.

Backup Power and Portable Supplies

Have you ever wondered how some off-grid installations or some military field equipment can be sustained? And that is PEMFC at work, more specifically in portable and backup applications where dependability is paramount.

Automotive Applications

FCV stands for fuel cell vehicles, and fuel cell vehicles have been developed to reduce the emission of greenhouse gases in the atmosphere.

This paper delves into one of the ever-growing sectors in the automobile industry, namely, the fuel cell vehicles. They also guarantee we can refuel our batteries within minutes and travel great distances with very minimal impact on the environment.

Role of Major Car Manufacturers

Hyundai, Toyota, and SAIC are some of the companies that are leading this transition. They have set small models and are now working on issues of dealing with large volumes and optimizing for cold environments.

Importance of Environmental Adaptability

Why Low Temperature Matters

Here’s the thing: In his opinion, fuel cells are wonderful only in mild climates. However, if the temperature goes down, the water, which did not pose a danger at a high temperature, turns into a threat, freezing and expanding to damage various intricate components.

Environmental Benefits vs. Technical Challenges

I have only found one disadvantage in the case of PEMFCs, and this common strength is the cause, namely, PEMFCs are eco-friendly. The water which they produce as a clean byproduct is a menace during winters, as it often leads to permanent damage and rapid efficiency depreciation.

In this part, we discussed some of the problems that arise when using PEMFC in low-temperature regions.

Water Production and Freezing Issues

Consider your fuel cell with the fuel being water that suddenly freezes into ice. It’s like putting gasoline into your car’s engine during the winter season. It can only cause a lot of problems. This is the central problem of using PEMFCs at low temperatures, as has been highlighted in the previous section.

Damage to Key Materials

Membrane Degradation

The key component of the PEMFC is the membrane, which can become brittle or even crack if the situation goes to the extent of freezing, and thereby, the features suffer a decrease.

Catalyst Layer Vulnerability

Catalysts are expensive and fragile. This will lead to poor efficiency or even complete failure of the cell when the temperature decreases; also, the lifetime of a cell is reduced.

Startup Failures in Cold Conditions

In the case of starting cold and not having infrastructure in place, it is worse. Like when you try to start a diesel truck without glow plugs – it’s painfully unreliable and will cause damage after some time.

Key Technologies and Solutions

Development of Low-Temperature Tolerant Materials

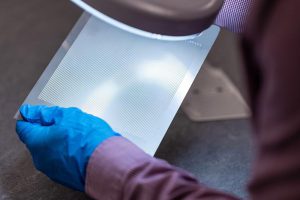

Novel materials of membranes, catalysts, and sealants are being developed and engineered to be more flexible and accommodate freezing conditions. These materials not only endure in cold conditions but also blossom in them.

Structural Optimization of Core Components

Gas Diffusion Layer Design

Advanced GDLs enable enhanced water control and, at the same time, the removal of vapour while retaining moisture in critical components.

Improved Catalyst Layers

Currently, researchers are using coatings and nano-techniques to enhance thermal and freeze-resistance in catalysts used by engineers.

Low-temp startup and shutdown procedures and some protective strategies. Low-temp startup and shutdown is a procedure used in power plants to warm up the turbines and shut down the equipment during the short seasons.

You would not leave your phone outside to freeze in the snow, would you? Just like other PEMFCs, the requested strategies, such as pre-heating systems and controlled water purging, as well as integrated safe shutdown sequences, are also critical.

Recent Breakthroughs and Innovations

International Progress and Standards

Due to the success of countries such as Japan and South Korea, the FCV cold-weather performance is already defined. The cars run perfectly, even though their owners take them out at -30°C, all due to the well-engineered product and precise systems integration.

Emerging Trends in Material Science

From graphene-based materials to self-healing membranes, the future of PEMFC in cold climates has all the elements of a good science fiction movie.

This article aims to compare domestic and global capabilities of resources, which are both tangible and intangible, in enhancing the knowledge of individuals.

Global Leaders (Hyundai, Toyota, etc.)

These companies are not only producing fuel cell vehicles but are also making them capable of running in snow. They have spent money on R&D and developed systems that are patented for their cold-climate functionality.

Gaps in Chinese PEMFC Technology

Manufacturing Challenges

However, there is one drawback, which is that the manufacturing stability for such materials as membranes and catalysts is slightly behind in China.

Research and Development Investments

There is a rising pattern towards tech funding, but there must be a long-term commitment to foster the readiness of tech structures to withstand the cold weather.

Real-World Applications and Test Results

Demonstration Projects in Harsh Climates

As long as it is set up correctly, field tests in the Midwestern United States or Inner Mongolia or Northern Europe will reveal that PEMFCs can work in subzero conditions.

Lessons from Pilot Programs

Real-world tests using test fleets and buses have shown that such issues as system integration, updating the software, and regular system maintenance are instrumental in achieving optimal performance in cold climates.

PEMFC in Cold Conditions

Commercialization Outlook

After eliminating most of the challenges, the day when PEMFC-powered vehicles would be in circulation, especially in cold climatic regions, is not so far off. The future is certainly clean, green and bracingly frost-free for voice-controlled, energy-efficient cars and so much more.

Role of Policy and Subsidies

Government funding for R&D, infrastructure establishment, and incentives for the use of PEMFCs will go a long way towards ensuring that the technology is accepted, particularly in cold climates.

Conclusion

PEMFCs are on the right track to becoming an everyday source of power, most especially in the transport sector. But just like in any other underdog movie, they have had to brave some freezing conditions throughout their struggle. Due to enhanced materials, innovative ideas, and strategic planning of the fuel cells, they are now tested to perform well even in freezing conditions. But more importantly, while the leaders of global complexity are already well established in the concepts involved, the followers are not far behind. The bleakness of the weather can be felt in the winter of PEMFC, but its future is looking rosy.