About TMN

Leading Photo Etching Company

Providing Precision Etched Metal Parts in Compliance with Standards

Accurate, Efficient, Reliable Chemical Etching Service

TMN was founded in 2011 ,as a leading photo chemical etching company in China ,TMN has own etching building for more than 4000㎡ with 3 floors ,4 fully automatic photo etching production lines with length of 8 meters ,more than 100 well-experienced workers,professional degree-qualified engineers and chemists team .

TMN is always on the way to develop groundbreaking photo chemical etching technology, until now TMN has offered services for worldwide customers who is engaged in different fields.

To reduce the production time from prototypes to high volume quantity for customers, TMN has individual large warehouse to amass a variety of raw materials with different thickness from 0.01mm to 2.0mm ,once getting the design file ,TMN could prepare photo-toolings and make the prototypes within 6 hours.

Tighter tolerances ,better accuracies ,finer features ,thinner precision components are the aims of TMN ,we aim at your satisfaction with our experience and recognised know how.

Why Partner With Us

Photo Chemical etching is a precision process of using a strong chemical solution to create the desired designs on the flat sheet of metal.

The main raw materials that TMN has etched are stainless steel 300 series ,brass ,copper ,aluminum ,titanium ,kovar ,nickel with thickness range from 0.03mm to 3.0mm ,the main products of TMN are below ,

- Ultra-thin and high precisioncustomized metal shims/ washers /gaskets /springs /apertures.

- Fuel cell bipolar plates & flow field plates with titanium and stainless steel 316L,the dimension large can be 800mm width and 1500mm length.

- EMI / RF shielding parts and covers with nickel silver material .

- Filter meshesand screens with micro holes and tolerance controlled within +/- 0.03mm.

- Lead frame with copper and brassand do gold & silver plating.

- Optical maskwith micro slit as 0.02mm thin.

- Shadow mask with custmized structures.

- Encoder discs with hundreds of grooves .

- Ophthalmic surgical knife

- Model puzzle parts for ship ,airplane ,house ,tank ,car ,castle ,building with stainless steel and brass.

TMN etched parts and sheets have been exported to different countries all over the world,the main marketings are United States ,England ,Germany ,Switzerland ,Austra ,France,Hungery,Isreal,Singapore,Vietnam,Malaysia,Thailand and so on.TMN has enough experiences to arrange delivery and prepare relative documents and COC certificates for Customs clearance and import checking issue.

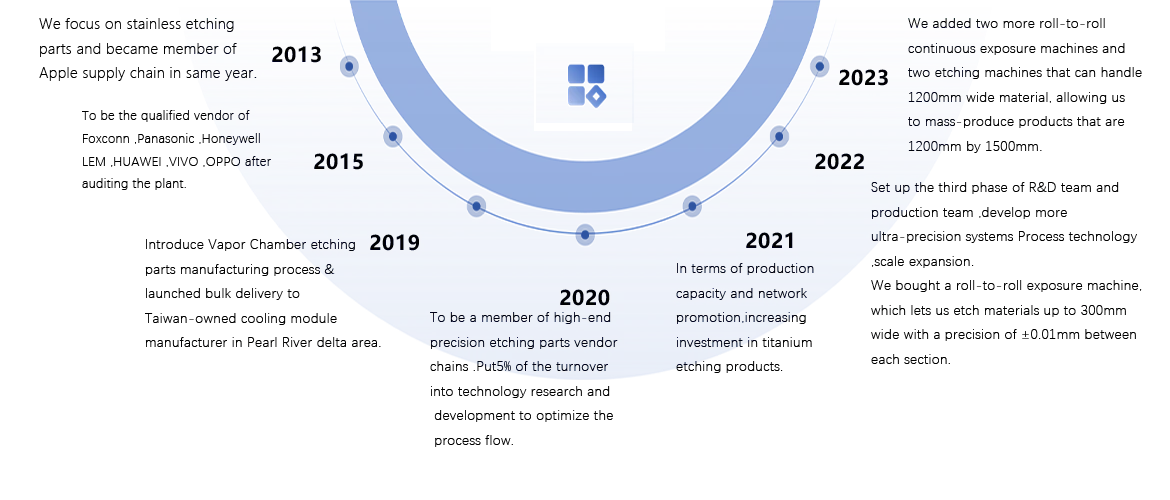

Development history

2013

We focus on stainless etching parts and became member of Apple supply chain in same year.

2015

To be the qualified vendor of Foxconn ,Panasonic ,Honeywell ,LEM ,HUAWEI ,VIVO ,OPPO after auditing the plant.

2019

Introduce Vapor Chamber etching parts manufacturing process & launched bulk delivery to Taiwan-owned cooling module manufacturer in Pearl River delta area.

2020

To be a member of high-end precision etching parts vendor chains .Put5% of the turnover into technology research and development to optimize the process flow.

2021

In terms of production capacity and network promotion,increasing investment in titanium etching products.

2022

Set up the third phase of R&D team and production team ,develop more ultra-precision systems Process technology,scale expansion.

same year

We bought a roll-to-roll exposure machine,which lets us etch materials up to 300mm wide with a precision of ±0.01mm between each section.

2023

We added two more roll-to-roll continuous exposure machines and two etching machines that can handle 1200mm wide material, allowing us to mass-produce products that are 1200mm by 1500mm.

Equipment Display

Automatic coating machine

Size:200*300 mm

Capacity:500 pcs/hour

Number:2 sets

High-speed exposure machine

Size:200*300 mm

Capacity:500 pcs/hour

Number:5 sets

ETching machine with 39 meters

Number:2 sets

Roll-to-roll continuous exposure machines

Number:3 sets

Cleaning and Developing machine

Size:300*400 mm

Capacity:500 pcs/set/hour

Number:5 sets

Fully automatic control

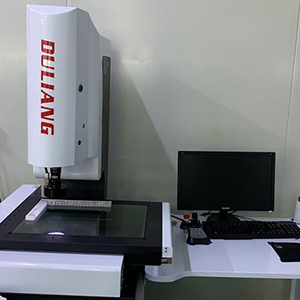

2.5 dimensional testing equipment

Range:300*450*100mm

The three-axis accuracy is≤0.001um,the probe and infrared measurement can be modified

Etching customization process

Step 1: Phototool Design / CAD Design

Our skilled engineers design precise phototools or utilize computer-aided design (CAD) to create digital blueprints for the desired metal component.

Step 2: Metal Selection & Prep

The appropriate metal material is selected based on project requirements, ensuring compatibility and optimal performance. The metal surface is meticulously cleaned and prepared for the photoresist coating.

Step 3: Photoresist Coating

A photoresist material is applied to the metal surface, forming a protective layer that will define the etching pattern.

Step 4: UV Exposure

The metal substrate is exposed to ultraviolet (UV) light through the phototool, which transfers the desired pattern onto the photoresist-coated surface.

Step 5: Development

The photoresist-coated metal is developed, removing the unexposed areas and revealing the etching pattern.

Step 6: Chemical Etching

The metal substrate undergoes chemical etching, where it is immersed in an etchant solution that selectively removes the exposed areas, leaving behind the desired etched pattern.

Step 7: Photoresist Stripping

The remaining photoresist is stripped from the etched metal surface, revealing the clean and precise etched features.

Step 8: Final Inspection

Each etched metal component undergoes a rigorous inspection process to ensure quality and accuracy before being released for delivery.

secondary processing capabilities

Metal Laser Cutting

Achieve precise and intricate cuts on etched metal components with our advanced metal laser cutting technology, ensuring accuracy and consistency.

Bending

Customize the shape and form of your metal components with our bending services, allowing for precise bends and folds to meet your specific requirements.

Polishing

Enhance the aesthetic appeal of your metal components with our professional polishing services, creating a smooth and lustrous surface finish.

Painting Colors

Add vibrant colors and finishes to your metal components with our painting services, providing endless possibilities for customization and branding.

Plating

Improve the durability and corrosion resistance of your metal components with our plating options, including various metal finishes and coatings for enhanced performance.

Stamping

Incorporate logos, serial numbers, or other identifiers onto your metal components with our stamping services, ensuring clear and permanent markings for identification and branding.

Client Feedback

U.K.

The shims that your factory produced are of really high quality, tight tolerance. I will send you more custom designs, please quote accordingly. --- Hans

Singapore

The quality of etched metal stencils is excellent, and it only took 5 days to get the metal stencils after confirmed drawings.--- Lewis

Thailand

After reviewing samples from several etching factories, we decided to try TMN, and the results exceeded expectations. Their chemical etching technology is top-notch.---Prasert

Germany

We've been partnering with TMN's for several years now, and our collaboration has always been pleasant, both in terms of the services provided and in our day-to-day interactions.---Felix

U.S.A

After visiting TMN factory by our quality team,I believe my company will establish a long term business relationship with TMN.The products and service that TMN provided are appreciated by the whole quality team.--- Dale

Switzerland

After having meetings with R&D team from TMN several times, my company is confident to cooperate with TMN, the R&D help my company to solve some problems efficiently.

--- Matthew

cooperating client

Send us a message

Whenever it is OK during working time, welcome to send an email to lydia.sales1@tmnetch.com or tmnetch@gmail.com in advance, we will pick up you from Shenzhen, Guangzhou or HK airport.