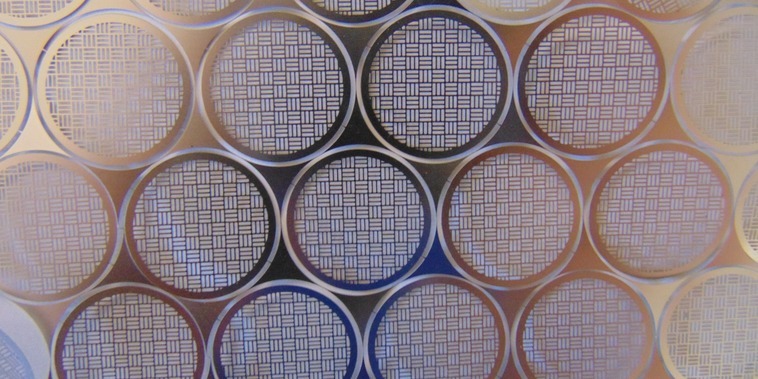

As its name describes, a metal mesh filter is a filter type that filters or sieves out various kinds of solid particles from either air or liquids. It is made up of metal wires or strands usually interwoven to make a mesh with their cut holes of predetermined sizes. Particle filtration capability of the filter is determined by the size and density of the apertures.

Metal mesh filters find applications in numerous industries including fresh air ventilating systems & air conditioning systems , microwave ovens, coffee machines , automobiles, cooktop range fan hoods etc. The metal mesh filters are considered as efficient alternatives since they are more durable, can withstand extreme heat and are reusable which make them useful in situations where ordinary filters would break down or be consumed within short periods of time.

Understanding Filter Mesh Size

Filter mesh size is a value given to the size of the opening in a mesh filter also stated as a high number of holes/more than one aperture in a unit or other units estimation. This special sizing is what determines how much of a given substance is filtered out and how much passes through.

- Mesh Count : Indicates the number of openings for one linear inch both in the horizontal and vertical directions as well. For instance a 100 mesh filter has a hundred openings within an inch area.

- Aperture Size: It is concerned with the dimension of the separate separations in the mesh which are quantified in microns or millimeters. The particle size is affected by the aperture – the smaller the aperture the smaller the particle level, the larger the aperture, the bigger the particles go through.

What’s The Meaning of ‘Mesh’ in filters?

‘Mesh’ in filters means the configuration which supports specialty filtration depending on the size of the particles. The wires are interwoven in a way to form a mesh which has structures that allow the finer particles to pass through but not the thicker ones.

Shelving 100 Mesh and 200 Mesh Side by Side

The 200 mesh filter is finer while its correlating 100 mesh filter is thick mesh. A mesh of 200 consists of 200 openings, inches wise while a 100 mesh consists of 100 openings per inch. Therefore, as the number of meshes increases, the sizes of screens also decreases hence the filters’ elements become finer than the single hundred mesh filter.

In cases where more fine particles need to be removed, then a 200 mesh filter might be the right choice. In case of less fine filtration, a 100 mesh filter might be the right choice.

Shelving 100 Mesh and 400 Mesh Side by Side

The 400 mesh filter is fine while the 100 mesh filter is thick. In the same way, the 400 mesh filter with a one-inch aperture has 400 holes leading to smaller openings hence it collects minute particles more effectively. The case of the 100 mesh filter is that the meshed filter is more effective in the large particle size.

Types of Mesh Filters

Metal Mesh Filters

Filters of Stainless Steel Mesh.

The stainless-steel mesh filter is more marketed because of its rustproof characteristics. They are, therefore, widely found in industries and kitchen use where the humidity and temperature conditions are usually modified regularly.

Filters of Copper and Aluminum Mesh

Copper and aluminum mesh are much lighter filters and cheaper too compared to the stainless steel reinforced mesh however are employed in applications which do not require strength.

Synthetic Mesh Filters

Other applications, such as water and air purification, have lower requirements, while others such as nylon mesh filters stifle synthetically make them. These offer better elasticity than the metal mesh but have a tendency to rupture before the latter does under certain circumstances.

Purpose of a Mesh Filter

The basic function of the metal mesh separation filter is the separation, capturing and/or removal of different particles, pollutants or other types of contamination from the air or liquid. This filters down so that larger particles are trapped but smaller ones are able to pass through and filtration of the required particles and levels for the intended application is achieved.

Why Mesh Filters Are Crucial to the Filtering Execution

Mesh filters are especially important when accurate retention of specific particle sizes is necessary. In industrial plants, kitchen exhausts and motors, mesh filters suffice and ensure that impurities are capturing ones improving the quality of air or liquids.

What are Mesh Filters Commonly Used For Application?

Air Filtration: High efficiency mesh filters are installed in HVAC units and purifiers to collect dust, pollution, and other suspended particulate matter.

- Fluid Filtration : They are used in automotive engine oil filtration, industrial fluid systems, and hydraulic fluid systems to filter impurities.

- Kitchen Applications : These are present in kitchen hoods to remove grease and food from the air and cut the clogging of the ventilation system.

- Industrial applications: They are used in chemical manufacturing, oil processing, and water treatment to safeguard equipment and ensure product integrity.

- Reusable filtration : Metal mesh filters that are reusable are appreciated for their ability to be washed and used again rather than being discarded like paper filters, thus allowing for greater cost-effectiveness and lower carbon impact.

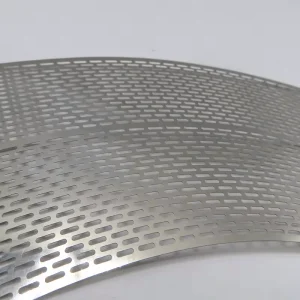

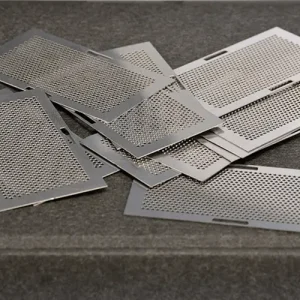

Custom Metal Mesh Filters.

The scope of custom metal mesh filters is based on a specific industrial application such as medical, auto motive, electronics, aerospace etc. They are sized, thickness, mesh and non woven fabric types in such a manner that they will perform well for the various applications.

Steps to Make Custom Metal Mesh Filters:

- Design Step : The size, shape, and mesh size of the filter are made to the customer’s needs. It is also very useful in making precise designs.

- Material Selection : Choosing several metal materials depending on the usage of stainless steel, copper, aluminum, and titanium. There is tolerance to these materials and these are temperature and corrosion.

- Manufacturing Process : Photochemical etching is able to accomplish detailed etching without formation of any burr and without any distortion.

- Quality Control : Production of filters involves effective quality control whereby the manufacturers perform inspections and quality measurements of the mesh and surface, overall performance of the filters and a great deal more.

Speaking of custom metal mesh filters, TMN’s professional manufacturers specialize in looking for optimal compromises for the customers, which makes it easy for usage and durable. For further information and bookin, contact Lydia.sales1@tmnetch.com or visit our Facebook page .