Introduction to PEM Cell Electrolyzers

Hydrogen production through Proton Exchange Membrane electrolyzers brings revolutionary changes to the hydrogen manufacturing process. PEM devices use electricity to yield oxygen and hydrogen from water through an environmentally clean method for green hydrogen generation. How PEM Cell Electrolyzers Work in Hydrogen Production? Let’s find out.

Electrolyzers remain the best option for sustainable energy systems because they bring together efficiency and minimal size with easy compatibility with renewable power sources.

How Does a PEM Cell Electrolyzer Work?

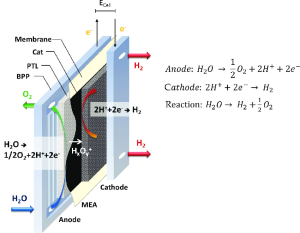

A PEM electrolyzer maintains its fundamental components as a proton-conducting membrane. The application of electricity causes water molecules to break into oxygen particles and protons together with electrons. Membrane protons move as electrons exit through the external circuit to combine oxygen and protons for hydrogen production . PEM electrolyzers remain the simplest system for generating pure hydrogen because of their effective operation mechanism.

Advantages of PEM Technology in Hydrogen Production

What sets PEM electrolyzers apart? The primary benefits of these electrolyzers include outstanding operational effectiveness and widest possible application ranges . PEM electrolyzers work well for different scenarios because their small size lets them integrate into industrial facilities and domestic applications. The capability to handle unstable power supplies makes PEM electrolyzers ideal for blending with renewable energy systems.

Hydrogen Fuel from Electrolyzers

PEM electrolyzers present a production method which creates hydrogen that offers wide applicability. The product of electrolyzers enables multiple applications including vehicular use and residential power needs as well as store-and-use capacity. The worldwide push for sustainable energy solutions depends heavily on the essential use of hydrogen for reaching complete emission neutral status.

Cost Analysis and Comparisons

Cheapest PEM Electrolyzer for Hydrogen

Looking for budget-friendly options? Multiple affordable PEM electrolyzer systems are available in the market for small commercial operations. The lower production capabilities of these units fit well with startup operations and educational purposes.

Cost Comparison: PEM vs Alkaline Electrolyzers

PEM electrolyzers provide superior long-term value due to their efficiency coupled with minimal operational expenses despite initial affordability of alkaline electrolyzers. PEM systems better serve future energy demands since they display superior flexibility when using variable power sources.

Innovations and Scaling

Innovations in PEM Hydrogen Production

The recent research effort has concentrated on developing membranes that last longer and removing the necessity of using platinum as a catalyst. PEM electrochemical devices can now be connected with wind turbines and solar panels to create an entirely sustainable production method.

Scaling Up PEM Electrolyzer Technology

The process of expansion encounters difficulties which involve expensive processes and necessary supporting infrastructure requirements. Governments and private sectors conduct extensive research and development to solve the present challenges and establish PEM electrolyzers as standard equipment.

Applications and Maintenance

Applications of PEM Electrolyzers

PEM electrolyzers serve multiple commercial sectors due to their ability to deliver energy as well as create hydrogen for off-grid operations. PEM electrolyzers remain vital because they generate pure hydrogen which manufacturers require in pharmaceutical and food processing operations and electronics industry production.

PEM Electrolyzers for Residential Hydrogen

The idea of running a home-based hydrogen production facility exists as a realistic possibility! PEM electrolyzers arrive in compact designs which enable home owners to generate clean energy through cooking and heating and to charge fuel-cell vehicles with it.

Maintenance Tips for PEM Electrolyzers

Regular maintenance represents the essential factor for maintaining optimal performance of your PEM electrolyzer system. Periodically clean your PEM electrolyzer membranes while checking for leaks to maintain security of all electrical components. The device lifespan extends significantly because of just minimal device care.

TMN Photochemical Etching Factory: Precision Solutions for Fuel Cell Components

The clean energy revolution depends on fuel cells which need high precision together with reliable and efficient components. TMN Photochemical Etching Factory serves as a trusted manufacturer and producer of fuel cell components through its expertise in photochemical etching technology for the hydrogen energy market.

Why Precision Matters in Fuel Cells

A chemical reaction drives fuel cells to generate electricity through the conversion of hydrogen fuel. Turbo efficiency requires that bipolar plates and flow fields and current collectors maintain strict dimensional precision. The photochemical etching methods used by TMN enable the manufacturing of parts that fulfill exact performance standards needed for fuel cell systems.

The fuel cell technology benefits substantially from TMN ‘s technological input.

High-Precision Bipolar Plates

The fuel cell depends on bipolar plates to perform two essential functions which include distributing gases and enabling electrical current flow throughout the system. TMN specializes in producing bipolar plates through photochemical etching that results in thin and lightweight yet corrosion-resistant components with complex flow field designs . The manufacturing process of these plates through photochemical etching results in uniform products with high levels of dimensional accuracy.

Custom Fuel Cell Components

The company delivers tailored solutions which serve different fuel cell applications. The factory provides specific components suitable for automotive applications as well as stationary and portable fuel cells which boost operational stability and performance.

Prototyping and Mass Production

From rapid prototyping to large-scale production, TMN supports every stage of fuel cell development. The factory maintains total flexibility in its production system which delivers fast response times together with excellent product quality.

Material Versatility

TMN operates with various materials found in fuel cells specifically stainless steel combined with titanium together with nickel. The team utilizes its specialist knowledge to develop components that fulfill all essential requirements which fuel cell systems demand including conductivity and lightweight specifications as well as corrosion mitigation properties.

- The company extends clean energy support through diverse metal-based services.

- The company provides additional services beyond fuel cell parts through which it helps advance the growth of clean energy solutions in specific areas.

- The company produces high-precision elements for hydrogen storage solutions to achieve safe and efficient operation.

- The photochemical etching process of TMN produces components necessary for creating advanced batteries which include current collectors and conductive plates.

Why Choose TMN for Fuel Cell Component Manufacturing?

The precision product offerings of TMN Photochemical Etching Factory benefit from innovative manufacturing approaches that implement versatile design with sustainable methods to create top-tier fuel cell components. The company utilizes green manufacturing processes which support the clean energy technology goals of fuel cells together with dedicated excellence standards to deliver premium products to clients.

As an industry leader TMN offers precision-made components for all fuel cell solutions used in transportation systems and industrial processes and residential energy generation.

FAQs

1. What is a PEM Cell Electrolyzer ?

It’s a device that uses electricity to split water into hydrogen and oxygen through a proton-conducting membrane.

2. Why Use PEM for Hydrogen Production?

PEM electrolyzers are efficient, compact, and ideal for use with renewable energy sources.

3. Is PEM Electrolyzer Cost-Effective?

While the initial investment may be higher, the efficiency and low maintenance costs make PEM electrolyzers a cost-effective option over time.

4. Can Electrolyzers Produce Green Hydrogen?

Absolutely! When powered by renewable energy, PEM electrolyzers produce 100% green hydrogen.