A lead frame is an important structure and an electrical part of a package in the semiconductor industry. It acts as a cradle for the silicon die, supports stable electrical connections, and facilitates heat dissipation from the chip when in use. In a lot of electronics, especially when it comes to performance, the lead frame manufacturing process quality is very critical. And with shrinking and more complex semiconductor designs, reliable lead frame fabrication services that follow industry standards are needed to keep them on track. If you don’t know how this component work, your engineers and buyers are unable to make more informed design and sourcing decisions.

What Is a Lead Frame?

The lead frame is an accurately manufactured metal structure in which an electronic package receives and interconnects the semiconductor chip. It mechanically supports the die and establishes robust electrical connections between the chip and external systems. The lead frame precision has a considerable impact on electronic signals and heat performance in most semiconductor packages. Modern equipment typically demands tighter tolerances, which is a further reason why numerous device manufacturers utilize custom lead frame designs to satisfy mechanical, electrical, and thermal conditions. Quality of the lead frame design provides lasting durability in even the most challenging electronic applications.

The Role of Lead Frames in Semiconductor Devices

A common popular type of semiconductor package is lead frame-based. Its performance relies on accurate design, meticulous production, and an admirable lead frame making process usually accompanied by specialized lead frame solutions plus professional lead frame manufacturing service.

Key Elements and Functions of a Lead Frame

- Mechanical Support for the Die

The semiconductor frame keeps the semiconductor dies in place during bonding and packaging processing. This anchorage of the parts prevents any displacement that would result in electrical or structural failure. - Electrical Pathway Formation

The inner and outer leads offer a conductive path from the die to an external circuit. - Thermal Management Capability

The metallic construction also allows for efficient removal of heat from the semiconductor die. Well, the better a device gets rid of heat, the longer it will last and perform at its best. - Compatibility With IC Packages

Custom lead frames are designed to comply with the undermentioned standard semiconductor package types. This makes it perfectly suitable for use in automated production lines. - Precision-Driven Manufacturing

Control of manufacturing leadframe to dimensional tolerances. Uniformity, of course, is also critical for mass production and quality assurance. - Design Customization Options

Use a custom lead frame to modify the arrangement of leads and thickness. Versatility is fitting different electrical, thermal, and mechanical requirements. - High-Volume Production Support

Stamped lead frame manufacturing provides consistent repetition and fast turn times. It is suitable for use in semiconductor manufacturing on a macro scale. - Cost and Material Efficiency

Best designs are material-minimizing at given weight strengths. This equilibrium maintains costs in control without compromising on quality. - Process Reliability and Consistency

When this component fabrication is done by a professional service, output stays consistent from batch to batch. Fewer defects mean you can produce more goods. - Long-Term Performance Stability

A custom lead frame will, in fact, live through temperature shock and physical stress. It results in durability and longevity under demanding high-output conditions

Types of Lead Frames and Common Materials Used

The mold is formed by a metal frame with various designs and materials for different semiconductor package needs. The optimal design of structure and material is crucial for electrical performance, heat dissipation, and process ability. For such advanced designs, there are even controlled lead frame manufacturing processes and specific metal frame that serve special application purposes.

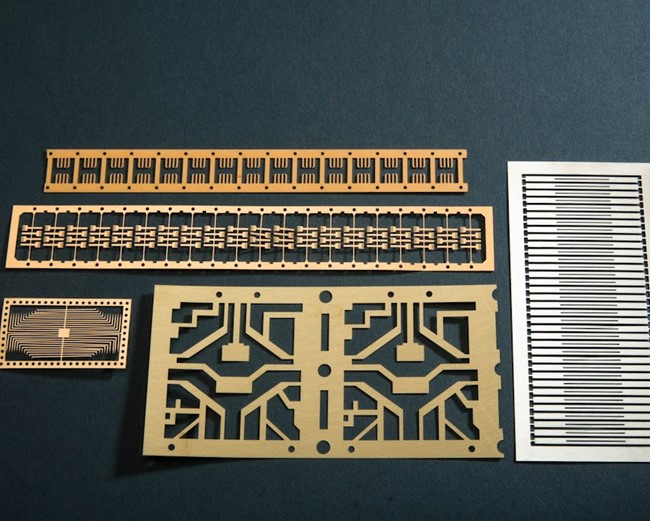

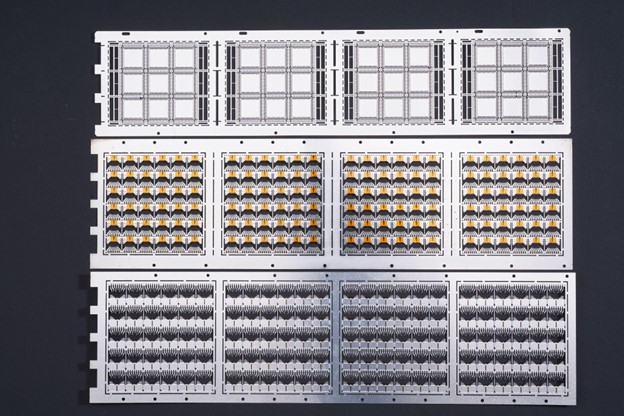

Common Types and Materials of Lead Frames

- Stamped Lead Frames: These are produced through a stamped metal frame process, which is best for high volume.

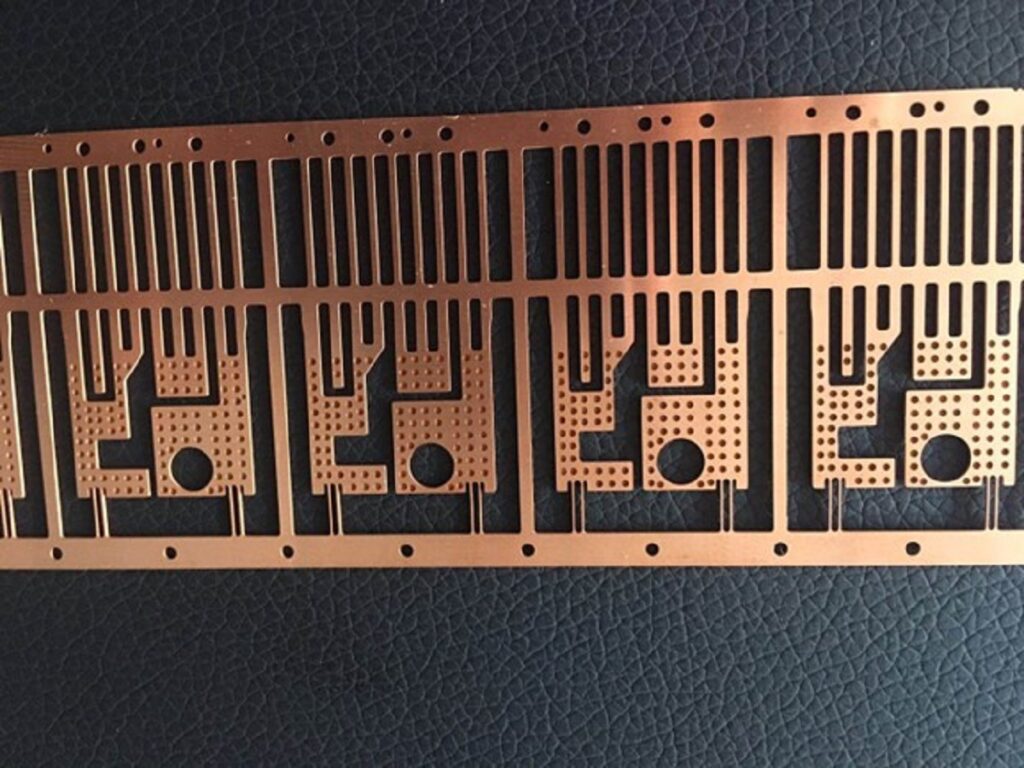

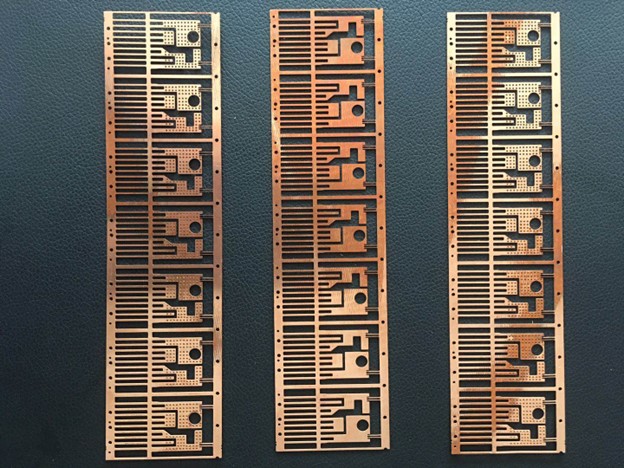

- Etched Lead Frames: Fine patterns and close tolerances can be achieved using chemical etching. It is the choice for complicated layouts and high-density packages.

- Copper Alloy Lead Frames: Copper-based alloys also have a high degree of electrical and thermal conductivity. They are extensively used in performance-oriented semiconductor systems.

- Iron-Nickel Alloy Lead Frames: These materials also have a high degree of mechanical integrity and controllable expansion. They are used in applications where high accuracy is necessary.

- Custom Material Lead Frames: Special alloys or coatings may be combined using a custom lead frame. This is beneficial in that it allows the introduction of details for electrical, thermal, or environmental purposes.

Lead Frame Manufacturing Process: Step-by-Step Guide

The lead frame manufacturing process is a high-precision, repetitive process used to fabricate quality housing frames of metal for semiconductor packaging. Every phase is focused on precision, such as the material and quality of lead frame fabrication services in many cases, meeting society standards.

Step-by-Step Lead Frame Manufacturing Process

- Material Selection and Preparation: You pick out strips of metal and clean them for uniform thickness and conductivity and level them.

- Pattern Formation: The lead for the layout can be made in etching the the structure manufacturing or stamping lead frame manufacturing, depending on the complexity of the design and quantity of production.

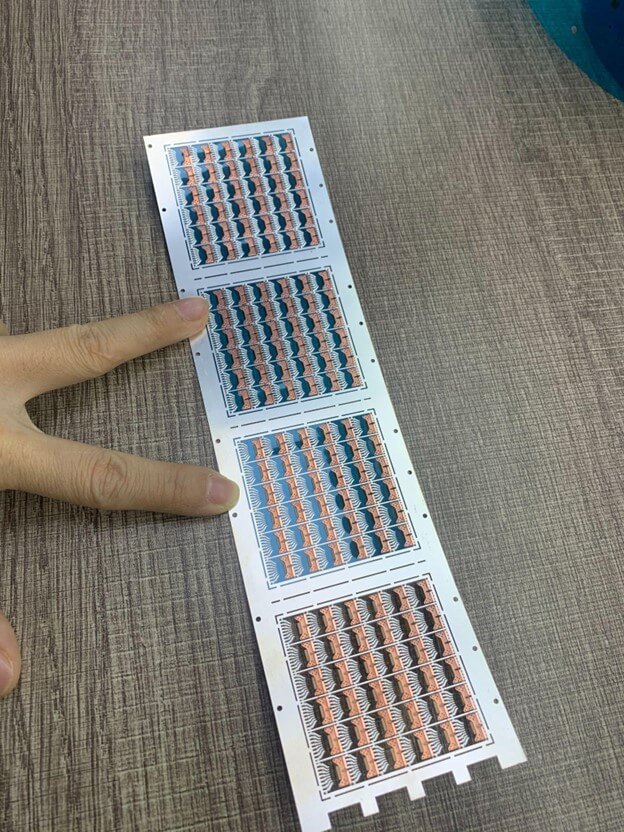

- Surface Plating Treatment: The plated lead form, silver, tin or the like is molded to perform solderability and electric characteristics

- Dimensional Inspection and Quality Control: Precise controls of lead pitch, thickness, and alignment enable matching the specs for the semiconductor.

- Final Packaging and Delivery: This component come in reels or strips to be formed for assembly and then integrated into semiconductor packages.

Etched Lead Frames: Precision Solutions by TMNetch

Etched lead frames create very fine dimensions in complex semiconductor designs that require tight tolerances and small geometries. The company offers a range of superior etched solutions based on process control, material competence, and established metal frame manufacturing services to the toughest specifications.

- High-Precision Patterning: Etching provides an ultra-fine pitch to enable fine-pitch packaging and stable electric properties.

- Optimized for Complex Designs: Custom lead frames are practical when an application calls for a specific the structure design, often because of performance or space constraints.

- Controlled Lead Frame Manufacturing Process: With tight process control, TMNetch can guarantee uniform thickness, a clean edge, and repeatable quality.

- Enhanced Reliability and Yield: Accuracy of etching minimizes mechanical stress and enhances the long-term reliability of a package in critical applications.

- Scalable Fabrication Support: “TMNetch’s lead frame fabrication services are well-suited for prototyping or high-volume production and do not sacrifice precision.

Applications of Lead Frames in Modern Electronic Devices

The frame is used in electronic devices as a structural support, helps to electrically connect the device, and also dissipates heat from, for example, an integrated circuit die or chip. Due to its flexibility, as well as improvements in the lead frame manufacturing process, it can be used for diverse electronic applications.

Consumer Electronics: Smartphones, laptops, and wearables are also produced with this component as compact mounting and reliable electrical connectivity options.

- Automotive Electronics: Also in the automotive sector, control materials and sensors are driven by durable packaging, including, as a rule, customer-specific L/F solutions for most. harsh environments.

- Power Management Devices: Provides high-end electrical performance that is reliable on the job.

- Industrial Equipment: The metal frame is used, and the stamping manufacturing process is short and inexpensive, suitable for a high-volume electronic device.

- Mass-Produced Electronic Components: PCB etched metal frame offer precision and intricate custom features in semiconductor devices with the smallest dimensions.

FAQs

1. What is the role of a lead frame in semiconductor packaging?

This component offer mechanical support and electrical interconnectivity for semiconductor devices. It is capable of being provided by controlled lead frame manufacturing processes and trustworthy lead frame fabricating services that can provide durability, conductivity and thermal stability.

2. When should manufacturers choose a custom lead frame?

A custom lead frame is the perfect solution when off-the-shelf options are unable to match the required electrical, thermal, or package needs. Performance may be further optimized for advanced or high-reliability semiconductor applications through customization of the metal frame process.

3. Why is stamped lead frame manufacturing widely used?

Stamped lead frame manufacturing is preferable, especially for high-speed, precision, and low-cost production. Choosing a reliable semiconductor frame for semiconductor manufacturer for the precise tooling, consistency of quality, and large production volume.

conclusion

A lead frame is one of the most important components in semiconductor packaging that significantly determines electrical performance, thermal management, and mechanical stability throughout its lifetime. Choosing the correct lead frame manufacturing process means consistent quality in low to high-volume production. For more sophisticated applications, a custom lead frame provides flexibility and performance. Teaming with experienced suppliers of lead frame fabrication services, such as TMNetch, effectively reduces the burden on manufacturers for production risk by offering a proven yield. Choosing the best lead frame semiconductor supplier is critically important for achieving mature, high-performance devices in a commoditizing electronics marketplace.