The holidays are a time to sparkle, and what better way to add some shine to your celebrations than with stunning custom metal ornaments? If it is intricately shaped snowflakes, family initials on ornaments, or any special design, these ones add a touch of class to any Christmas tree.

But have you ever thought what stands behind these lovely works? The secret often lies in the clever use of two modern fabrication techniques: etching and laser cutting. This means that employing both of these approaches will allow for a great many possibilities of creativity and accuracy , ideal for creating your holiday aesthetics.

What does the term ”photochemical etching” mean?

Photochemical etching is a technology that relaxes light-sensitive chemicals to strip metallic material. This technique can produce patterns at the micro level almost down to as fine as one millimeter. It is most suitable for fine, aesthetic work which needs fine detailing.

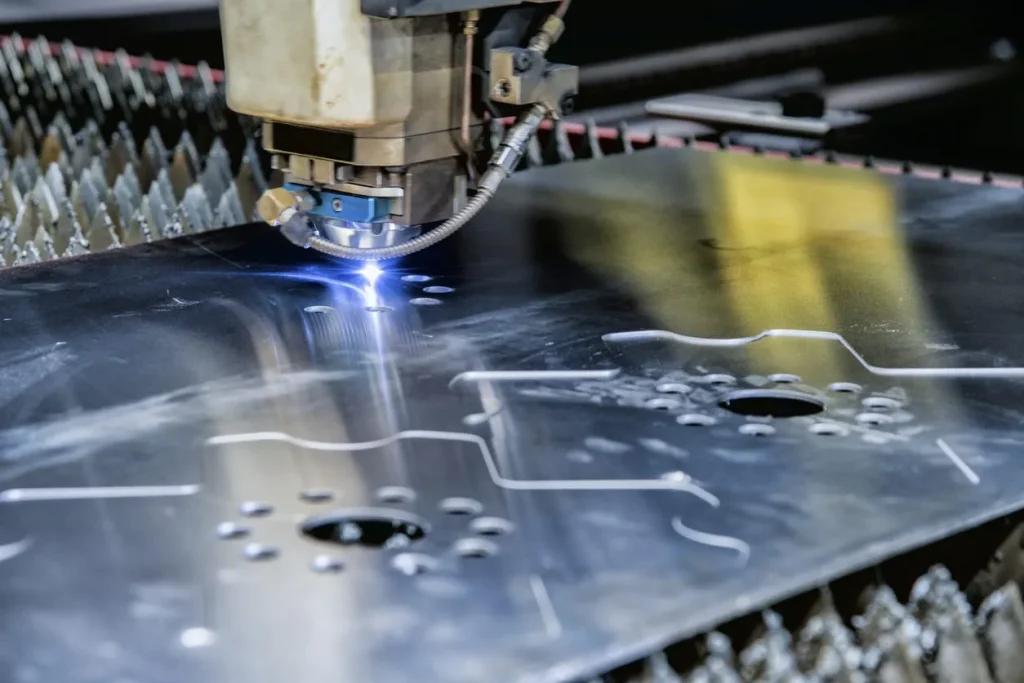

How Does Laser Cutting Work?

Laser cutting includes the use of a light beam to cut through particular material with precision. It’s unique and will work on almost any metal for cutting smooth edges and intricate designs within seconds.

Pros of Photochemical Etching

High Precision in Design

The designs that are possible to work out on the photochemical etching are remarkably complex and almost unattainable with other physical etching techniques. How about a snowflake design, a filigree angel design? This method is able to address the most mundane of concerns.

Ideal for Complex Patterns

The biggest asset of etching is in the ability to achieve thin and detailed engravings; therefore, it is popular for metal ornaments with elaborate designs or, engraved names.

Advantages of Laser Cutting

Speed and Efficiency

Laser cutting is effective when you require ornaments to be cut quickly with accuracy, and none of the elements need to be added afterward. Its speed helps you cope with a huge number of objects in its processing.

Versatility Across Materials

Unbelievable for metals, it also performs on acrylic, wooden, and others offering luxury for your creative purposes.

An integration of Etching and Laser Cutting

That is how the two techniques complement each other.

Meanwhile, etching has the fine details and laser cutting has the speed, so the two put together are unbeatable. Etching is suitable for precise details because lasers are excellent for cutting amazing shapes, while laser cutting helps to achieve sharp contours.

Improvement in the Quality of Design and Strength of metal ornaments

Together they make custom ornaments that are not only appealing but also quite sturdy, so they could be used year after year during the festive season.

Christmas metal ornament application wishes

Drawing Beautiful Snowflakes and Stars

Snowflakes and stars are normally complex designs that can be enhanced by etching’s fine lines and laser cutting’s sharp edges.

Personalized name ornaments

The next best thing to having engraved invitations.

To increase sales, gifts that are engraved must be personalized and when both methods are used, they allow clear font engraving.

Two Dimensional and Thrice Dimensioned Plans

One more idea is to glue etched pieces on top of the laser bases to make metal ornaments more three-dimensional and to stand out against the tree.

Environmental Considerations

Eco Friendly Materials for metal Ornaments

It is now possible to get green metals and green materials from many of the manufacturers, so all your ornaments are environmentally friendly, as well as elegant.

Cutting Snack Loss Down to a Fine Art

Etching will also reduce on the wasteage of the material used in the production process as it is also similar to laser cutting. When etching and laser cutting go hand in hand, the businesses and customers get the best for a reasonable price.

Using both etching and laser cutting for custom metallic Christmas ornaments is the perfect way to bring creativity, precision, and durability together. These techniques go very well together; therefore, the possibilities are limitless, both regarding uniqueness, complications, and sustainability when it comes to the holiday decorations. Both the consumer searching for special decorations and the business which needs to provide something special should take this solution.

Visit our LinkedIn page for more information.

FAQs

How do etching and laser cutting differ from one another?

Where etching is intended for surface designs, laser cutting is for shaping/cutting through objects.

What material is best for metallic Christmas ornaments?

For Christmas ornaments, any metal would do, but for precise ornaments, a lightweight material such as aluminum or brass is ideal.

What is the impact of laser and etching techniques on the durability of ornaments?

This combination guarantees high durability ensuring ornaments that do not wear out over the years.

Where can I find manufacturers who have both techniques?

There are several specialized metal fabrication companies that provide this type of service. TMN is China’s Top high precision company that has experience with both etching and laser-cutting for optimum results.