Metal fabrication is an integral part of the current industrial process where metals in their raw form are converted to their finished products by cutting, bending, welding, and assembling. Be it in the construction of towering tall buildings or delicate gears and cogs of a machine, this keeps the formulation of the industries going.

What Is Metal Fabrication?

Overview of the Process

Metal fabrication entails the process by which metal is put into usable parts or structures. It goes from the cutting phase and shaping preparation to welding and assembly parts.

Key Applications

Within almost all industries, fabricated metal parts are used ranging from auto manufacturing to airplane construction as well as other projects.

Types of Metal Fabrication Methods

Cutting

Cutting comes first before fabrication as it determines the outline shape of the metal pieces using utilities such as laser and saw.

Bending

Metal forming that gives it the required shape by using presses or rollers is called bending.

Welding

This process connects parts made of metal together in a rigid

hence being a structural unit.

Assembly

The last step integrates all the efforts in building a whole structure or end product.

Metal Fabrication Techniques

Traditional Methods

Among these are the following: tape cutting, bending, and welding; these are manual operations, and the work has to be done by artisan labor.

Modern Techniques

Automation through fabrication methods such as CNC machines and laser cutting has enhanced fabrication to its present standard.

Custom Metal Fabrication

Services Specialized Programs for Particular Industries

Special orders meet specific requirements within an industry, for example, manufacturing or architectural creations.

Examples of Custom Projects

Some of the common examples of objects realized out of the pipe material include a casing for electronics, ornamental structures, and industrial work.

Sheet Metal Fabrication Process

Stage beginning from Design to end product

The process involves design and prototyping, material choice, cutting as well as forming, forming, and then assembly.

Tools and Equipment Used

Examples are computer numerical control machines, press brakes, and shear.

Welding and fabrication are very closely related; however, they are two different processes.

Different Positions in Production

Again, welding centers only on the connection between the surfaces, while fabrication involves stages of material selection to the final product.

How They Are Related

Welding is usually strategic in the large fabrication process since it is used to ensure that the joints are strong.

CNC Metal Fabrication

Automation in Precision Manufacturing

CNC machines operate from a computer,

with the tool being operated by a computer program that could not be paralleled by a human hand.

Applications and Advantages

Whether for automotive spare parts, or aerospace components, CNC fabrication is known for its durability and minimal manufacturing waste.

Structural Metal Fabrication Examples

Bridges and Skyscrapers

Complex entities such as bridges require fabricated metal beams and joints for their construction.

Heavy Machinery

Some of the many uses of metal fabrication include manufacturing and providing spare parts to sectors such as mining and agriculture with reliable metal parts.

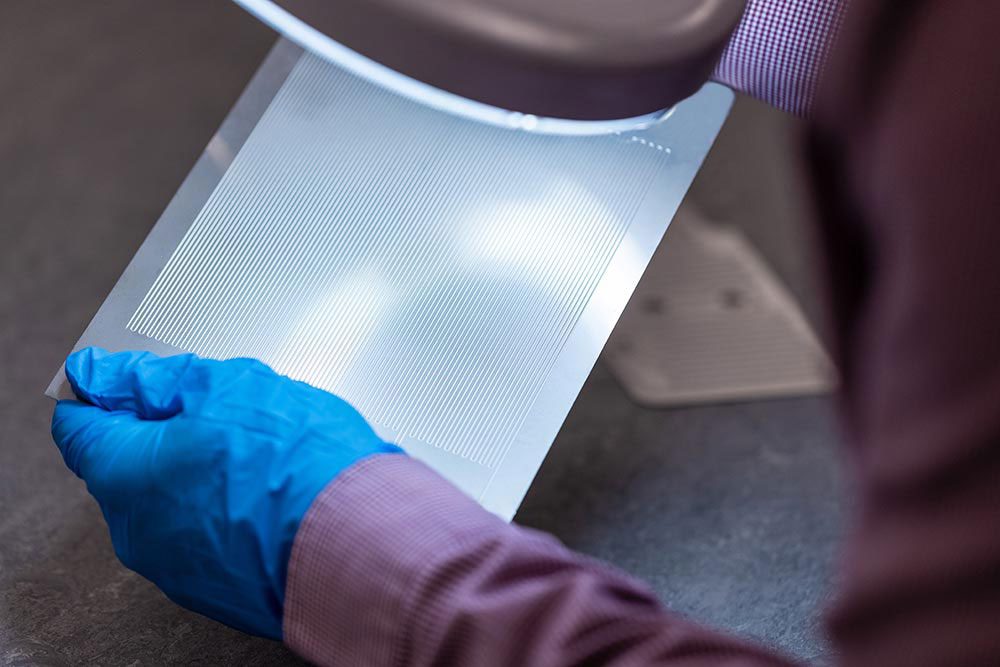

TMN Photochemical Etching Factory: A Leading Player in the Precision Metal Fabrication Business

Specialty in Etching Parts

TMN mainly focuses on photochemical etching, which is a process of micromachining the intricate parts of metal

Contributions to Innovation

Its sophisticated methods improve the manufacturing of such parts as filters, screens, and other complex shapes needed in the aerospace and medical industries.

Metals and their alloys are crucial in developments which makes our current world stand out. While including simple methods to more complex ones such as those provided by the TMN Photochemical Etching Factory, it remains a constantly developing industry that shows potential for a sustainable future.

Contact Lydia.sales1@tmnetch.com or visit our Facebook and LinkedIn page for further information.

What kind of metal mesh can be made by photochemical etching?

FAQs

What is the most common type used for cutom metal fabrication?

Cutting and welding are the most frequently used methods in metal fabrication.

What are the best cutom metal fabrications near me?

TMN provides photochemical etching services for high-precision components and export globally.

How does CNC fabrication improve precision?

CNC machines use precise programming to achieve consistent results with minimal error.

What industries benefit most from custom metal fabrication?

Automotive, aerospace, and construction industries benefit significantly from custom fabrication.

How does TMN support advanced metal fabrication?

TMN provides photochemical etching services for high-precision components, enhancing innovation.

Is metal fabrication eco-friendly?

Yes, especially with advancements in recycling and sustainable material practices.