ETCHING ELECTRONIC COMPONENTS

Miniaturization, Efficiency,

Cost-effectiveness

The TMN photo etching process revolutionizes electronic products, making them lighter, thinner, more economical, and more efficient.

Trusted industry-leading brand

Advantage

Discover how TMN's innovative photochemical etching process offers unparalleled advantages for electronic components:

Precision

Achieve intricate and precise designs with unparalleled accuracy, ensuring optimal performance of electronic devices.

Material Compatibility

Our versatile process is compatible with a wide range of materials, allowing for flexibility in component design and functionality.

Complexity

Easily fabricate intricate and complex geometries, allowing for the production of highly sophisticated electronic components.

Cost-effectiveness

Benefit from cost-efficient manufacturing processes, reducing overall production expenses without compromising quality.

Material Savings

Minimize material waste through efficient etching processes, maximizing resource utilization and reducing environmental impact.

Scalability

From prototype to mass production, our photochemical etching process seamlessly scales to meet varying production demands with consistent quality.

Thinner and Lighter

Produce electronic components with reduced thickness and weight, enhancing portability and integration in electronic systems.

Burr-Free Edges

Enjoy smooth and burr-free edges on etching components, ensuring optimal functionality and aesthetic appeal.

Experience the unmatched advantages of TMN's photochemical etching process for your electronic component manufacturing needs.

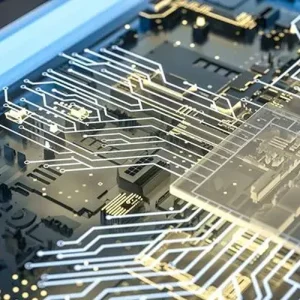

Common Etching electronic components

TMN leverages years of experience in the electronic industry and a state-of-the-art photochemical etching facility to produce a diverse range of high-quality electronic components.

Lead Frames and Connectors

Precision-cut lead frames and connectors ensure secure connections and reliable performance in electronic assemblies.

Shielding and Enclosures

Custom-designed shielding and enclosures provide electromagnetic compatibility and protection for sensitive electronic circuits.

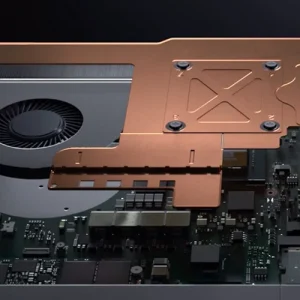

Vapor Chamber

Efficient vapor chamber manufacturing enables thermal management solutions for high-performance electronic devices.

Mesh Filters

Fine mesh filters with precise openings offer effective particle filtration for various electronic applications.

Shims, Washers & Spacers

Tailored shims, washers, and spacers ensure proper alignment and spacing in electronic assemblies, enhancing functionality and reliability.

Encoder Disks

Utilize encoder disks for precise motion control and feedback in electronic systems, enabling accurate positioning and speed monitoring.

Flexible Electronics

Advanced etching techniques enable the fabrication of flexible electronic components for applications requiring bendable and stretchable designs.

Microelectronics

High-precision etching processes deliver intricate microelectronic components with unmatched accuracy and consistency.

Sensors and Actuators

Customized sensors and actuators enable precise measurement and control in electronic systems, enhancing functionality and performance.

RFI Finger Strip

Effective solutions for mitigating electromagnetic interference (EMI) in electronic circuits, ensuring signal integrity.

Experience the reliability, precision, and versatility of TMN's electronic components manufactured through advanced photochemical etching processes. Contact us today to discuss your specific requirements.

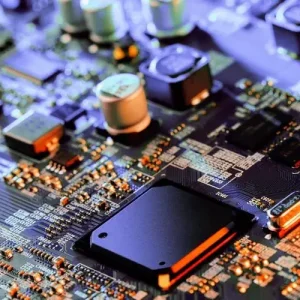

Common Metal Materials for Etched Electronic Components

TMN, a trusted name in chemical etching, offers an extensive selection of metal materials for the production of electronic components. With expertise in etching various metals, we ensure the highest quality and precision in every component.

Nickel

With excellent conductivity and magnetic properties, nickel is commonly used in electronic components such as connectors, batteries, and sensors.

Stainless Steel

Stainless steel offers durability, corrosion resistance, and hygienic properties, making it suitable for a wide range of electronic enclosures, connectors, and structural components.

Brass

Brass combines excellent electrical conductivity with malleability, making it ideal for electronic connectors, terminals, and decorative elements.

Aluminum

Lightweight and corrosion-resistant, aluminum is widely used in electronic housings, heat sinks, and structural components to optimize weight and thermal management.

At TMN, we leverage our expertise and advanced etching techniques to meet the specific requirements of electronic component manufacturing. Partner with us to access a diverse range of metal materials and unlock the full potential of your electronic projects.