TMN’s Successful Projects (High Precision Metal Shims)

High Precision Metal Shims For Well-known German Medical Equipment Brand

Launched in 2018, this Successful project (High Precision Metal Shims) has been ongoing to the present. A renowned German medical equipment brand discovered TMN through Google. Following initial discussions between our engineering R&D team and their sales team, both parties signed a non-disclosure agreement (NDA).

Shortly after, the client provided detailed drawings, marking the beginning of a successful collaboration.

More Information About this project

The general information is as follows:

- Raw Material: NiCo alloy (Ni 86%, Co 14%)

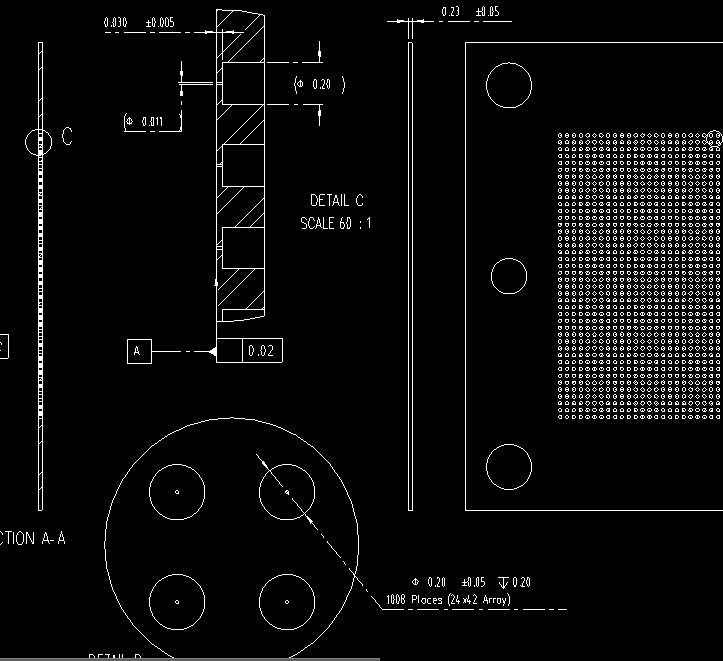

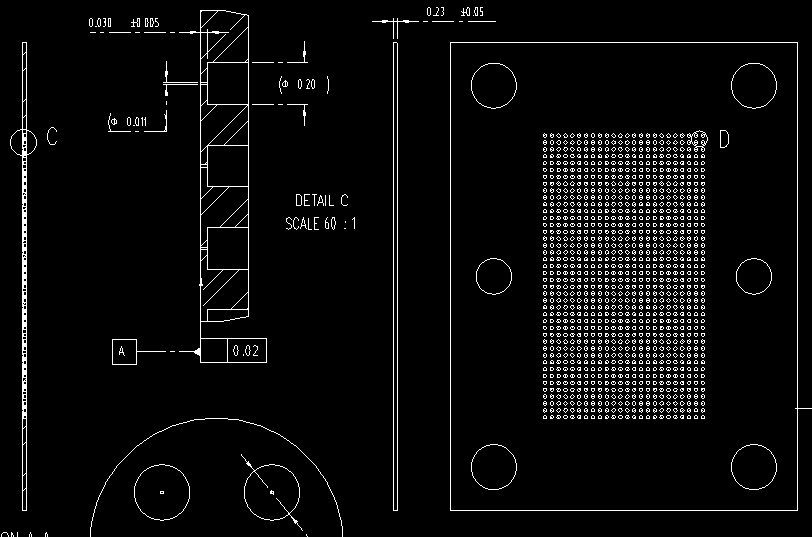

- Thickness: 0.23 mm

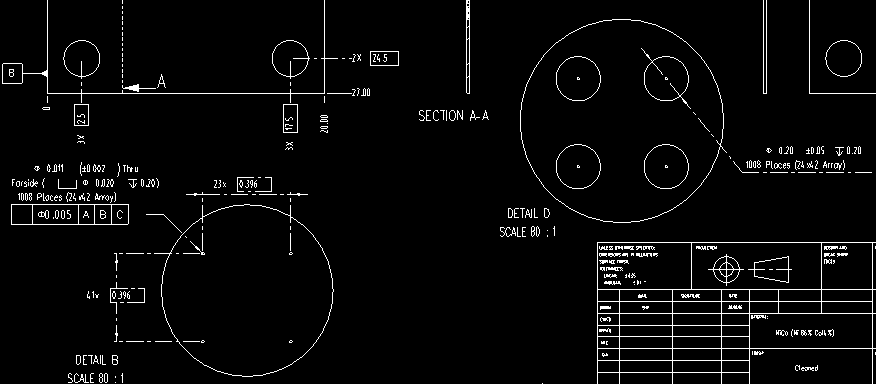

- Outside Dimension: 20 mm × 24 mm

Etching layers

There are 4 etching layers:

- First Layer: Etching 4 through holes with a diameter of 2.5 mm.

- Second Layer: Etching 2 through holes with a diameter of 2.05 mm.

- Third Layer: Etching 24 × 42 = 1,008 holes with an etched depth of 0.2 mm. The diameter of these holes is 0.2 mm.

- Fourth Layer: Etching 24 × 42 = 1,008 holes with a diameter of 0.011 mm and a thickness of 0.03 mm. These holes are located in the center of the 0.2 mm holes.

High-Precision Metal Slit for Light Beam Filtering

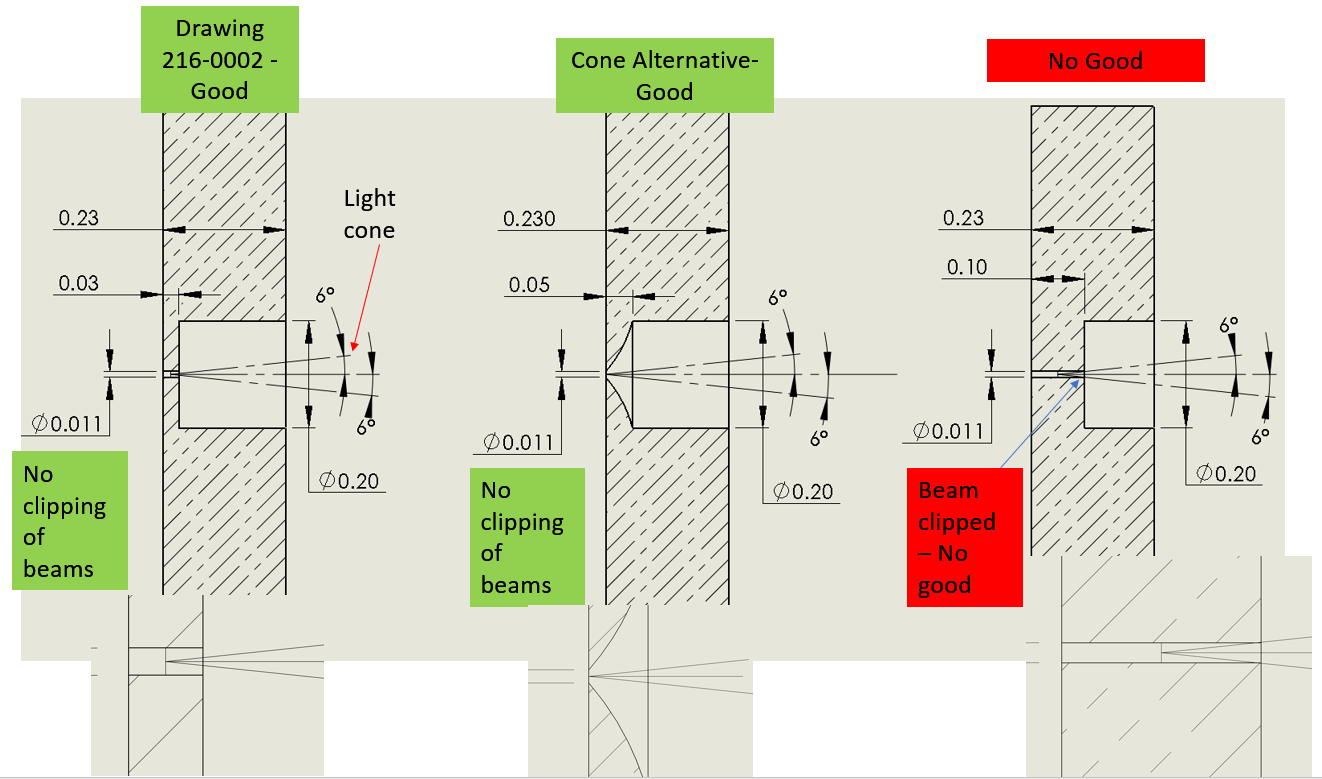

This high precision metal slit functions as a filter for different light beams, requiring exceptional accuracy. Due to its intricate design, manufacturing this component is extremely challenging, especially in processing micropores at the hole center.

The Technical Challenge

The core challenge lies in creating a 0.011 mm micropore within a 0.2 mm diameter hole. This level of precision is difficult to achieve, making the manufacturing process highly complex.

Advanced Manufacturing Process

TMN employs a two-step approach to achieve the required precision:

- Etching Process: The initial 0.2 mm hole is formed using a high-precision etching technique.

- Laser Micromachining: High-precision laser equipment is then used to create the 0.011 mm micropore at the exact center of the hole.

Throughout the entire process, precise positioning is critical. Additionally, the extremely high scrapping rate makes mass production nearly impossible.

Overcoming the Challenges

Despite the difficulties, the TMN team remained persistent. After two months of continuous efforts, they successfully achieved mass production of this complex component. This milestone not only marked a technical breakthrough but also became a valuable and unforgettable experience for the team.

Innovation and Growth

By continuously tackling such challenges, TMN has repeatedly pushed the boundaries of technological innovation. This dedication to overcoming technical bottlenecks has allowed the company to grow, manufacture increasingly sophisticated high-precision metal products, and secure more collaborations with world-renowned brands.

Why TMN is the Best Choice for Your Custom Needs

At TMN, we specialize in delivering high-precision metal components tailored to meet the most demanding requirements. With years of experience, cutting-edge technology, and a commitment to excellence, we ensure superior quality and reliability in every project.

Here’s why TMN stands out for your custom manufacturing needs:

1. Expertise in High-Precision Metal Fabrication

Our team excels in producing complex metal components with extreme accuracy. Whether it’s high-precision metal shims, filters, or intricate micro-components, we meet the tightest tolerances with unmatched precision.

2. Advanced Manufacturing Capabilities

We utilize state-of-the-art etching, laser machining, and CNC technology to achieve exceptional precision. Our ability to work with various metals ensures versatility across different industries, including medical, aerospace, electronics, and automotive.

3. Customization to Meet Your Exact Specifications

Every project is unique, and we pride ourselves on offering fully customized solutions. From prototype development to mass production, we work closely with clients to meet their specific design, material, and performance requirements.

4. Commitment to Quality and Precision

Quality is at the core of everything we do. With strict quality control measures, advanced inspection techniques, and adherence to international standards, we guarantee high-performance and defect-free products.

5. Trusted by Global Brands

TMN has built strong partnerships with leading global companies, proving our ability to deliver consistent, high-quality solutions. Our successful collaborations with renowned brands highlight our reliability and expertise in precision manufacturing.

6. Fast and Efficient Production

Our optimized processes ensure quick turnaround times without compromising accuracy. Whether you need a small batch or large-scale production, TMN delivers on time with precision and efficiency.

Partner with TMN for Your Custom Precision Needs

If you’re looking for a trusted manufacturer for high-precision metal shims and custom metal components, TMN is your ideal choice. Contact us today to discuss your project and experience the TMN advantage!

With our expertise in high-precision metal fabrication, we turn complex challenges into successful solutions.