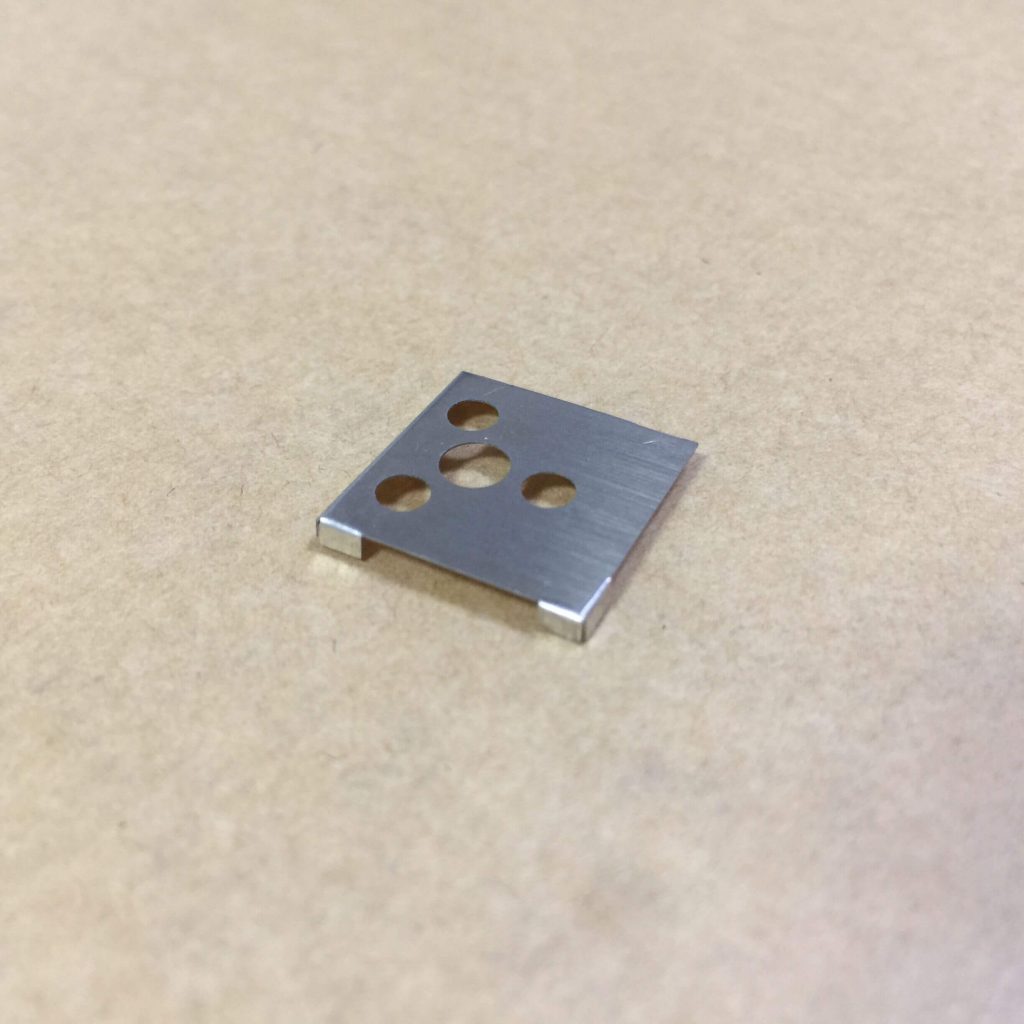

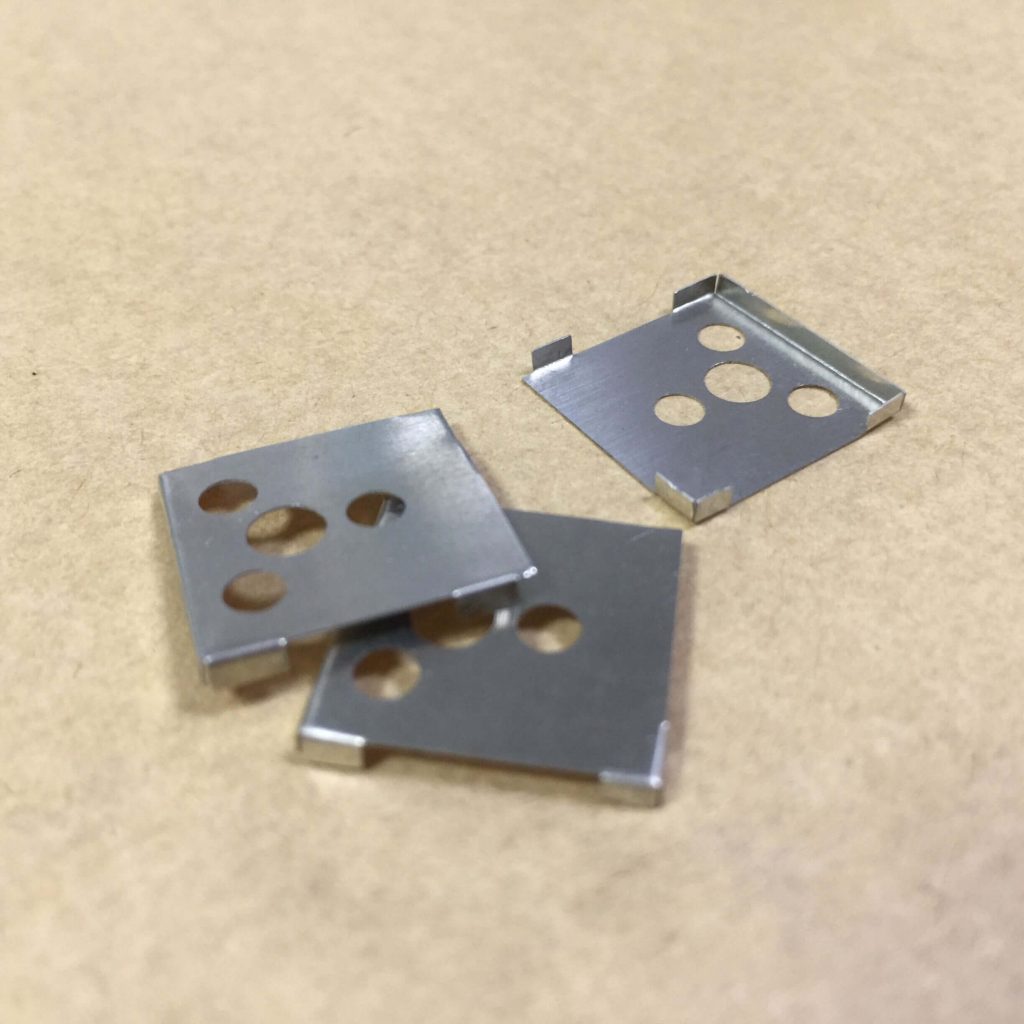

Custom Nickel Silver EMI RFI Shielding Parts

High-Performance Shielding Solutions by TMN Metal Parts Fabrication Factory

In today's high-speed, high-frequency electronics environment, electromagnetic interference (EMI) and radio-frequency interference (RFI) are persistent challenges. These types of interference can compromise signal integrity, lead to data loss, and cause electronic devices to malfunction or fail regulatory compliance tests. At TMN Metal Parts Fabrication Factory, we specialize in designing and manufacturing Nickel Silver EMI/RFI shielding parts that offer superior protection, excellent durability, and outstanding performance.

As a leading manufacturer in precision metal fabrication, TMN is trusted by global clients across industries such as telecommunications, consumer electronics, medical equipment, automotive electronics, and industrial control systems. Our expertise in working with nickel silver allows us to provide customized, cost-effective, and reliable shielding solutions that meet the most demanding specifications.

Why Choose Nickel Silver for EMI/RFI Shielding?

Nickel silver, also known as German silver or NS alloy, is a non-magnetic metal composed primarily of copper, nickel, and zinc. It is widely favored for EMI/RFI shielding applications due to its unique balance of electrical, mechanical, and corrosion-resistant properties.

Key Benefits of Nickel Silver Shields:

- Excellent Shielding Effectiveness:

Nickel silver provides strong attenuation of both electric and magnetic fields, making it ideal for shielding high-frequency signals in compact electronic assemblies. - Corrosion Resistance:

The presence of nickel enhances the metal’s resistance to oxidation and environmental degradation, ensuring long-term durability in various operating environments. - Non-Magnetic Properties:

Because it is non-ferromagnetic, nickel silver does not interfere with magnetic components, which is critical for shielding sensitive electronic systems. - Solderability and Workability:

Nickel silver is easy to form, stamp, and solder, allowing for precise fabrication and reliable integration into PCB assemblies. - Aesthetic Appearance:

With its clean, silver-like surface finish, nickel silver provides a professional appearance and does not require additional plating for most indoor applications.

Our Manufacturing Capabilities

At TMN Metal Parts Fabrication Factory, we use advanced fabrication technologies and high-precision tooling to produce nickel silver shielding parts in a variety of shapes and sizes. Our production process is designed for efficiency, repeatability, and customization.

Capabilities include:

- Progressive stamping and deep drawing

- CNC machining and laser cutting (for prototypes or low volumes)

- In-house tool and die development for complex part geometries

- High-speed production for large volume orders

- Spot welding and assembly of multi-part shields

- Surface treatment and optional plating (tin, nickel, etc.)

- Shield design consulting and engineering support

Our skilled engineering team works closely with each client to develop shielding components that fit their unique PCB layouts and performance requirements. Whether you need a simple one-piece can or a complex multi-cavity shielding cage, we deliver with accuracy and consistency.

Types of Nickel Silver Shields We Manufacture

We offer a comprehensive range of standard and custom EMI/RFI shielding components using nickel silver. These include:

1. One-Piece Shield Cans

These are single-piece metal enclosures that cover sensitive circuit areas. They can be attached via soldering or through press-fit pins. One-piece cans are cost-effective and easy to install for high-volume applications.

2. Two-Piece Shields (Cover and Frame)

A two-piece shield includes a base frame that is soldered to the PCB and a removable cover. This design allows easy rework or testing of components during prototyping, assembly, or repair. It is particularly popular in RF and wireless module applications.

3. Multi-Cavity Shields

For densely populated PCBs with multiple noise-sensitive zones, we produce multi-cavity shields that isolate several areas within one integrated component. These are ideal for advanced communication and signal processing devices.

4. Custom Shields

Our factory specializes in custom shielding designs to meet non-standard form factors or unique shielding challenges. We can accommodate irregular PCB layouts, heat dissipation requirements, and grounding needs.

Applications of Nickel Silver Shielding Components

Nickel silver is a versatile shielding material used in a wide array of industries. TMN’s nickel silver shielding parts are commonly found in:

- Wireless Communication Devices: Shielding for Bluetooth, Wi-Fi, and 5G modules

- Consumer Electronics: Smartphones, tablets, and wearables

- Automotive Systems: ECU (engine control units), ADAS (advanced driver-assistance systems), infotainment systems

- Medical Devices: Monitoring systems, imaging devices, and diagnostic instruments

- Telecommunication Equipment: Routers, base stations, and satellite systems

- Industrial Control Panels: PLCs, motor controllers, and sensors

Quality Assurance at TMN Metal Parts Factory

At TMN, we are committed to delivering zero-defect quality. Every part undergoes strict inspection throughout the production process. Our quality control team checks for:

- Dimensional accuracy

- Flatness and planarity

- Consistency in material thickness

- Shielding effectiveness

- Surface finish integrity

We use automated optical inspection (AOI), calipers, micrometers, and shielding test equipment to ensure every product meets or exceeds client expectations. TMN also complies with ISO quality management systems and industry standards such as RoHS and REACH.

Customer Support and Engineering Partnership

TMN goes beyond manufacturing – we are your engineering partner. From early-stage prototyping to full-scale production, our team provides expert guidance on:

- Shield design optimization

- Material selection

- Thermal and mechanical integration

- Cost reduction strategies

- Assembly process compatibility

We aim to streamline your supply chain by offering fast lead times, flexible MOQ (minimum order quantity), and responsive technical support.

Environmental Responsibility

TMN Metal Parts Fabrication Factory is dedicated to sustainable and environmentally responsible practices. Our manufacturing process is designed to minimize waste, recycle metal scrap, and reduce energy consumption. We comply with all environmental regulations and ensure our products are safe and eco-friendly for global markets.

Why TMN Metal Parts Fabrication Factory?

Choosing TMN means partnering with a manufacturer that understands the complexity of modern electronics and the importance of reliable shielding. Our strengths include:

✅ Over 10 years of experience in EMI/RFI shielding production

✅ Advanced machinery and in-house tooling capabilities

✅ Fast response time and flexible manufacturing volumes

✅ Competitive pricing with no compromise on quality

✅ Global shipping and support for international clients

Contact Us Today

Looking for a dependable supplier of high-quality Nickel Silver EMI/RFI shielding parts? TMN Metal Parts Fabrication Factory is ready to help you meet your design goals with precision-engineered solutions.

Our Team And Factory