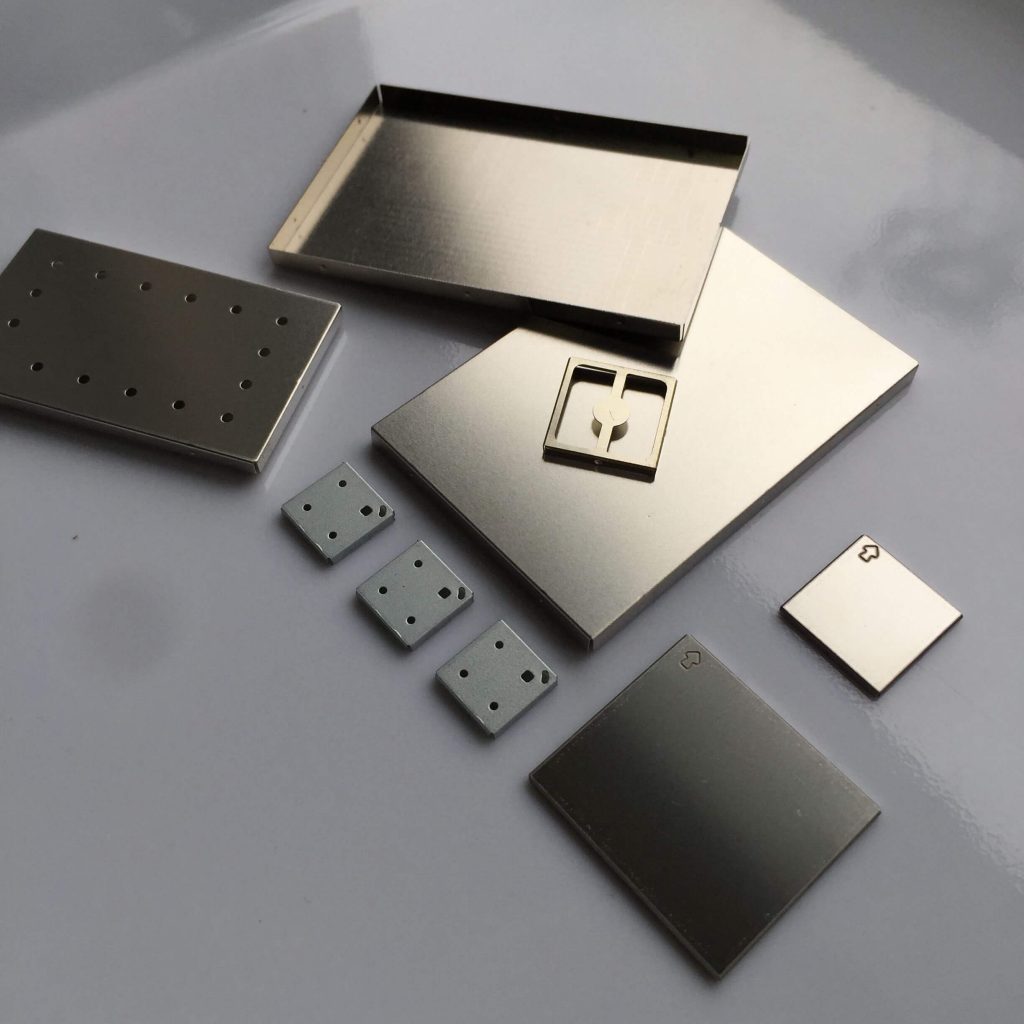

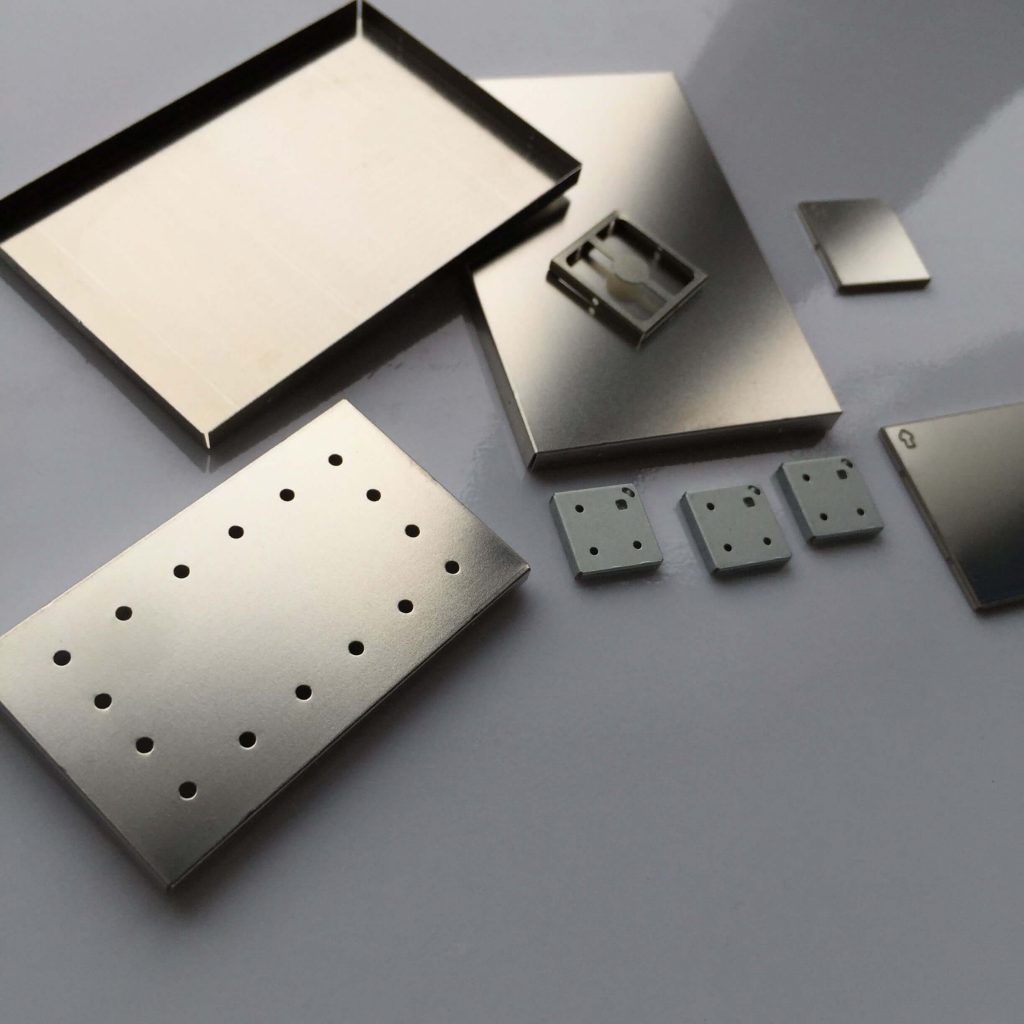

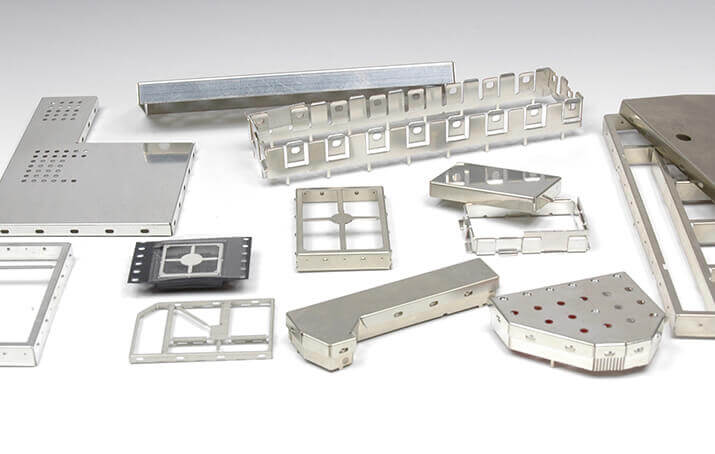

Custom EMI & RFI Shielding

At TMN Metal Parts Fabrications, we specialize in high-quality custom EMI (Electromagnetic Interference) and RFI (Radio Frequency Interference) shielding solutions tailored to meet the unique requirements of your electronic applications. With the rapid advancement of electronics, the need for reliable Custom EMI RFI Shielding protection has become more critical than ever. Our precision metal fabrication capabilities and engineering expertise enable us to deliver customized shielding products that enhance the performance, reliability, and compliance of your devices.

Why EMI/RFI Shielding Is Essential

In today’s increasingly connected world, electronic devices emit and receive a wide spectrum of electromagnetic signals. While this interconnectivity enhances functionality, it also increases the risk of interference. EMI and RFI can cause disruptions, degradation, or even complete failure in electronic systems. This interference can originate from internal components, external sources, or a combination of both.

Industries such as aerospace, defense, telecommunications, automotive, consumer electronics, and medical technology rely heavily on effective EMI/RFI shielding to:

Prevent signal interference

Ensure device functionality and safety

Achieve compliance with regulatory standards (e.g., FCC, CE, MIL-STD)

Protect sensitive data and intellectual property

Enhance the lifespan of critical components

What We Offer

At TMN Metal Parts Fabrications, we understand that no two projects are exactly alike. That’s why we provide customized EMI/RFI shielding solutions crafted to your specifications. Whether you need a simple metal cover or a complex multi-part assembly, our team can design, fabricate, and deliver the optimal solution.

Custom Shielding Capabilities:

Materials

We work with a wide range of EMI shielding materials including:Stainless steel

Copper

Brass

Aluminum

Nickel alloys

Mu-metal (for low-frequency magnetic shielding)

Our team can help you select the best material for your application, balancing conductivity, permeability, durability, and cost.

Fabrication Techniques

Using advanced fabrication technologies, we produce high-precision shielding components, including:Deep drawing

Laser cutting

CNC punching and bending

Welding and brazing

Stamping and forming

Spot and seam welding

Machining and finishing

Design Assistance

TMN’s experienced engineering team collaborates with you to:Optimize shield geometry

Reduce assembly time

Maximize shielding effectiveness (SE)

Ensure compatibility with your existing components

Prototyping & Low-to-High Volume Production

From initial prototypes to full-scale production runs, we support all phases of your product development. Our scalable production capabilities allow us to maintain consistent quality at any volume.Surface Finishes & Plating Options

To enhance corrosion resistance and conductivity, we offer:Tin, nickel, silver, and gold plating

Passivation

Anodizing

Powder coating

Conductive coatings (e.g., EMI gaskets, shielding sprays)

EMI Gaskets & Sealing Solutions

For enclosures and connectors, we also provide:Conductive foam gaskets

Fabric-over-foam solutions

Beryllium copper finger stock

Elastomer-based seals with conductive fillers

Applications of EMI/RFI Shielding

Our shielding solutions are trusted across a variety of applications:

Medical Equipment: Shielding sensitive devices like MRI machines, diagnostic equipment, and wearable medical devices to prevent false readings and ensure patient safety.

Telecommunications: Protecting data centers, routers, antennas, and 5G infrastructure from signal degradation and cross-talk.

Automotive & EVs: Shielding ECUs, sensors, infotainment systems, and battery packs in electric and hybrid vehicles.

Aerospace & Defense: Meeting strict MIL-STD requirements for communication equipment, avionics, radar systems, and satellite payloads.

Consumer Electronics: Ensuring performance and compliance in smartphones, laptops, gaming consoles, and IoT devices.

Industrial Equipment: Protecting PLCs, control panels, and robotics from environmental interference in harsh operating environments.

Compliance & Quality Assurance

TMN Metal Parts Fabrications is committed to delivering high-performance shielding components that meet stringent industry standards. Our quality assurance processes include:

In-house inspection and testing

Material certification and traceability

Compliance with industry regulations such as:

RoHS and REACH

FCC and CE

MIL-STD-461 and MIL-STD-810 (for military applications)

We understand that regulatory compliance isn’t optional — it’s a requirement. That’s why our team works closely with your engineering and compliance departments to ensure that all shielding components meet or exceed required standards.

Why Choose TMN for EMI/RFI Shielding?

Decades of Expertise: With years of experience in precision metal fabrication and EMI shielding, we understand the complexities of modern electronic systems.

Customization: Every project is tailored to your unique application — from design to production.

Advanced Technology: We invest in cutting-edge machinery and tooling to ensure accuracy, repeatability, and efficiency.

Fast Turnaround: Our streamlined processes allow us to meet tight deadlines without sacrificing quality.

Customer Focused: We pride ourselves on responsive communication, technical support, and a partnership-based approach.

From Concept to Completion

When you partner with TMN Metal Parts Fabrications, you gain more than a supplier — you gain a trusted collaborator. We support you throughout the entire product lifecycle:

Consultation: Discuss your EMI/RFI shielding needs, constraints, and goals with our expert team.

Design & Engineering: We’ll co-develop an optimized design using 2D/3D CAD models and electromagnetic simulations if needed.

Prototyping: Rapid fabrication of prototypes for real-world testing and validation.

Production: Scalable production with consistent quality and on-time delivery.

Support: Ongoing technical and logistical support as your project evolves.

Contact Us Today

Ready to enhance the performance and reliability of your electronic systems with precision-engineered EMI/RFI shielding? TMN Metal Parts Fabrications is here to help.

Whether you're developing a new product, upgrading an existing design, or need help meeting regulatory standards, our team is ready to deliver the custom shielding solution you need — on time and within budget.

Contact us today to learn more about our capabilities or to request a quote. Let’s build something exceptional together.

Our Team And Factory