The malfunction of electronic devices in sensitive industries can be caused by electromagnetic interference (EMI) and radio-frequency interference (RFI) disruptions. That’s where EMI and RFI shielding come in. Shielding prevents devices from being affected by unwanted signals. Here, so many engineers and companies wonder: what is EMI and RFI, how EMIRFI shielding works, which materials for electromagnetic interference in electronics are the best?

This blog post examines the basics of EMI and RFI shielding, along with common EMI/RFI shield materials and popular EMI/RFI shielding applications. As a pioneer in precision etching technology, TMNetch offers innovative shielding components for industries requiring precision and reliability.

What Is EMI and RFI?

Before we explore materials and applications, let’s clarify what EMI and RFI are.

- EMI(ElectroMagnetic Interference): The effect of one electromagnetic field on the performance of an electronic circuit.

- RFI (Radio Frequency Interference): Refers to a type of EMI that particularly happens in the radio frequency spectrum (in the range between 3 kHz and 300 GHz).

Either of them can negatively impact system performance, result in data loss, and do sensitive components harm as well. As the pace of technology rapidly advances to include more electronics in products, e.g., aerospace, automotive, and telecommunications, effective EMI and RFI shielding has become a design requirement.

How EMI/RFI Shielding Works

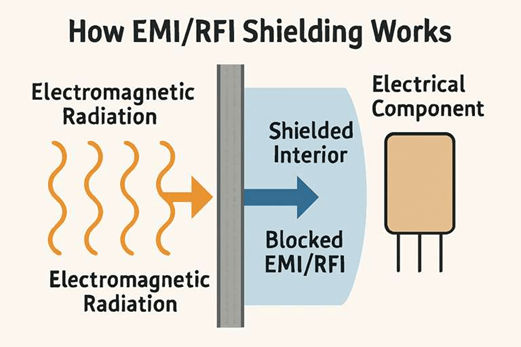

In other words, if you want to figure out how EMI/RFI shielding works, picture a wall between you and someone else that either bounces the sunbeams off of it or sucks them in. A containment of shielding material is housed about electronic components to inhibit the ingress of EMI with respect to the device or for the egress of EMI from the device.

Core Mechanisms:

- Reflection: Conductive shielding reflects incoming EMI/RFI signals back to the sources, away from sensitive electronics.

- Absorptive: Materials (ferrite or composite) separate and absorb undesired energy to release it as heat.

- Grounded: Shielding is usually grounded to allow any extra energy to dissipate.

- Containment: A well-designed EMI/RFI shielding helps to keep the interference from a device inside, where it belongs, rather than allowing it to escape and interfere with another device.

- Isolation: Sensitive circuits are isolated from high-power components using selective EMI/RFI shielding materials.

- Filtering: Shields commonly are deployed with filters to eliminate high-frequency noise and demonstrate a direct benefit of EMI/RFI shielding applications.

When added together, the effects of EMI and RFI shielding protect equipment from degradation, or false signals, allowing for accurate readings and stability to remain within regulated standards.

Why EMI and RFI Shielding Matters

- Device Protection: EMI and RFI shielding ensures hardware and data protection from harmful interference, so your devices will survive all of life’s (or work’s) mishaps.

- Industry Compliance: Devices are expected to be free from electrical interference, and EMI/RFI shielding materials maintain device safety and compliance.

- Reliability in Key Systems: Proves how EMI/RFI shielding works to protect aerospace and medical technologies that cannot fail.

- Better Communication: Used for EMI/RFI shielding applications provides a clearer signal to avoid the loss in telecommunications devices, medical equipment, and consumer electronics.

- Support Innovation: EMI and RFI Shielding allows to help design smaller, more advanced products without degrading performance.

When utilizing off-the-shelf or modified EMI/RFI shielding materials, the results are safer, more reliable products.

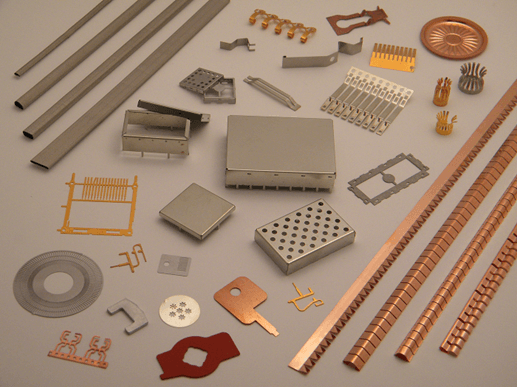

EMI/RFI Shielding Materials

Selecting the right EMI/RFI shielding material is critical to performance. Metals and composites have various levels of conductivity, permeability, and weight.

Common Materials:

- Copper: High-conductivity material used in flexible shielding and circuit boards.

- Aluminum: Low-weight design material based on cost for enclosures.

- Nickel: It’s corrosion-resistant and is appropriate for use in an abrasive environment.

- Steel: Offers efficiency of conduct and magnetic shielding.

- Conductive Coatings & Films: Typically applied on plastics or composites, designed for less demanding applications.

Here at TMNetch, we employ the method of chemical etching to produce accurate EMI/RFI shielding products that are also intricate with very tight tolerances; something needed in aerospace and telecom.

Why Choose TMNetch for EMI and RFI Shielding?

With increased industries calling for higher accuracy, TMNetch has been leading the way in EMI and RFI shielding technology.

- Precision Etching: Precision etching technology for fine details and smooth designs.

- Variety of Materials: Copper, aluminum, nickel, stainless steel.

- Customization: Shielding solutions for aerospace, medical, and telecom requirements.

- Experience & Confidence: supporting worldwide industries with high-quality solutions.

- Worldwide Service: TMNetch provides EMI and RFI shielding to businesses across the globe with quality that can’t be matched and customer service that won’t disappoint.

- Proven Performance: Decades of experience above and beyond EMI/RFI shielding in the harshest of real-world operating conditions.

When it counts, TMNetch is the protection that gets the job done.

EMI and RFI Shielding Advantages

There are several benefits to providing your product with good EMI and RFI shielding, including:

- Greater Device Reliability: EMI and RFI shielding protects sensitive electronics, thereby maintaining device stability and the integrity of its performance.

- Regulatory Compliance: The quality control and EMI/RFI shielding materials of our surface mount transformers ensure that they comply with emission standards around the world.

- Durable Product: Shows, in cutting down EDI/RFI shielding, how it protects circuits from permanent EMI/RFI damage.

- Increased Safety: EMI and RFI shielding is essential in aerospace and medical applications to ensure the right innovation.

- Cost-Effective: Properly chosen EMI/RFI shielding materials can lower expensive repairs and maintenance.

- Design Flexibility: Today’s EMI and RFI shielding materials accommodate small designs and many EMI/RFI shielding application requirements.

The advantages of both standard and custom EMI/RFI shielding materials are certainly safer, more reliable technology.

EMI/RFI Shielding Applications

EMI/RFI shielding application is required in a variety of different industries. Wherever electronics connect, there’s shielding to keep signals from interfering with each other.

Key Application Areas:

- Aerospace and Defense: Protect EMI-sensitive avionics, radar, and communication systems.

- Automotive: A safe choice for ADAS and infotainment.

- Medical Devices: Guards pacemakers, diagnostic equipment, and monitoring devices against external noise interference.

- Consumer Electronics: Mobile phones, tablets, and laptops need protection for signal integrity

- Telecommunications: Both base stations and 5G systems require high levels of protection for the stable transfer of data.

And by meeting these EMI/RFI shielding application needs, you will avoid failures and meet compliance. TMNetch bespoke EMI and RFI Shielding for these essential systems, custom-made shielding products. This equipment is supported with purpose-made shields.

FAQs

Q1. Why EMI and RFI Shielding is Important?

Emi and rfi shielding is important as it stops interference that can cause failures, loss of data, or safety issues, for example, in aerospace, automotive, medical, and telecom applications.

Q2. How and why to use EMI/RFI Shielding in applications?

How EMI/RFI shielding works is by absorbing, reflecting, and grounding unwanted electromagnetic fields that surround sensitive electronics with effective emi/rfi shielding materials.

Q3. What are common EMI/RFI shielding materials?

The most popular EMI/RFI shielding material is formed of copper, aluminum, nickel, and conductive coating, which are chosen based on conductivity, durability, and the requirements of its application.

Q4. Where is the EMI/RFI shielding application most important?

The need for EMI/RFI shielding matters most in equipment such as medical devices, aerospace systems, telecommunications, and consumer electronics to maintain their performance & safety.

Conclusion

This article included an overview of shielding, including what EMI and RFI are, as well as how EMI/RFI shielding works. With proper EMI/RFI shielding material and attention to design, interference can be effectively addressed in countless EMI/RFI shielding application areas. For applications where performance is critical, TMNetch develops creative EMI and RFI shielding technology for the mission-critical demands of accuracy, compliance, and long-term reliability.