The Evolution of Electric Vehicles

Over the past century, electric vehicles (EVs) have evolved from a mere concept into a revolutionary force shaping the future of transportation. Despite their humble beginnings in the late 19th and early 20th centuries, early EVs faced numerous challenges, including limited range, lengthy charging times, and inadequate performance. However, with the increasing urgency of environmental issues and the relentless advancement of battery, motor, and charging technologies, electric cars have undergone a remarkable transformation, heralding a new era in road travel.

As awareness and experience with electric vehicles grow, an increasing number of consumers are embracing renewable energy and EVs. They seek to reduce carbon emissions and lower the overall cost of vehicle ownership. Concurrently, manufacturers are striving to meet stringent emissions regulations, driving innovation and investment in cleaner, more sustainable transportation solutions.

Manufacturing the Bipolar Plates for Fuel Cells

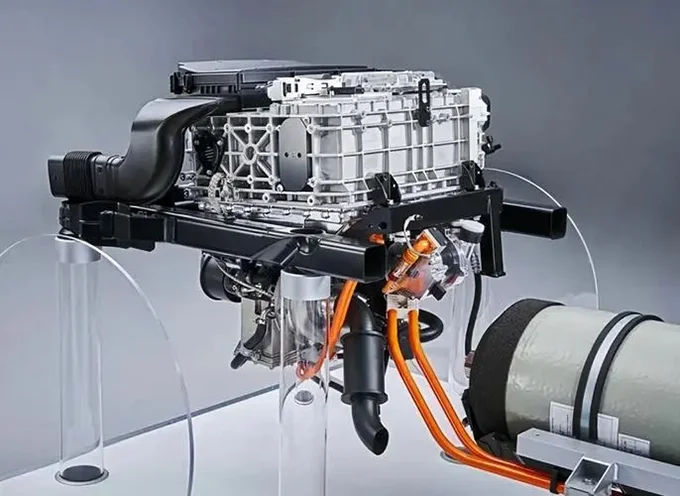

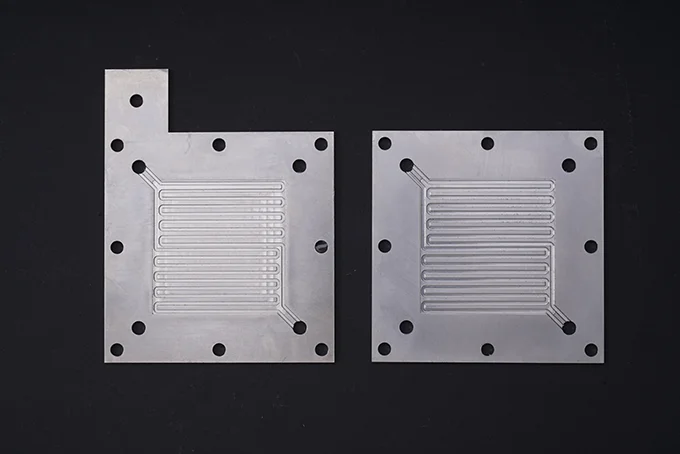

Integral to the success of electric vehicles is the advancement of fuel cell technology, particularly Proton Exchange Membrane (PEM) fuel cells. These devices play a crucial role in converting hydrogen and oxygen into electricity. At the heart of PEM fuel cells lies the bipolar plate, a key component situated at either end of the fuel cell stack. Responsible for facilitating the input of hydrogen and oxygen into the electrolyte membrane and outputting the generated current to the external circuit, the manufacturing process of bipolar plates is paramount.

Enter TMN’s company, pioneering the forefront of photochemical etching for bipolar plates. Through advanced photochemical etching techniques, TMN’s enhances catalytic efficiency, improves mass transfer properties, enhances stability and durability, and enhances electrochemical performance. These advancements contribute to the overall enhancement of PEM fuel cell performance and stability.

Advancements in Bipolar Plate Manufacturing and Fuel Cell

Advancements in Bipolar Plate Manufacturing

The current state-of-the-art process of photo etching process ensures high productivity and precision in producing bipolar plates, with channel and contour accuracy as low as +/-0.025 millimeters. Unlike traditional metal sheet processing methods such as hydraulic forming and stamping, photo etching process does not affect the flatness of the plate or introduce stress and burrs that could compromise stack bonding.

Future Trends in Bipolar Plate Manufacturing

Looking ahead, as manufacturing technology continues to evolve and innovate, the application of photo etching process in bipolar plate manufacturing is expected to expand further. Trends include:

– Process Optimization: Further refining the parameters and equipment design of photo etching process to enhance processing efficiency, precision, and surface quality, meeting higher demands in bipolar plate manufacturing.

– Intelligent Manufacturing: Integrating digitalization and smart technologies to achieve automated control and real-time monitoring of the photo etching process process, enhancing production efficiency and consistency.

– Material Innovation: Developing novel materials and alloys to improve bipolar plate performance and durability while meeting the requirements of photo etching processprocessing.

– Environmental Sustainability: Further optimizing the photo etching process process to reduce energy consumption and waste generation, aligning with goals of environmental protection and energy efficiency.

Full Support for PEM Fuel Cell Development

The use of Proton Exchange Membrane (PEM) fuel cells extends beyond road vehicles; they are currently in nascent stages of application in aerospace and defense sectors. However, with technological advancements and continued research investment, they are poised to play increasingly significant roles in the future.

These are just a few reasons why fuel cell engineers should consider photo etching process for bipolar plate production, with TMN’s playing a crucial role in pioneering innovative technologies.