Etched nameplates are more than just labels; they’re essential tools for identifying, branding, and ensuring the safety of equipment and products. These durable designable solutions support all segments of industrial applications. This guide explores everything you need about etched nameplates, including their benefits, materials, processes, and applications.

What Are Etched Nameplates?

Definition and Purpose

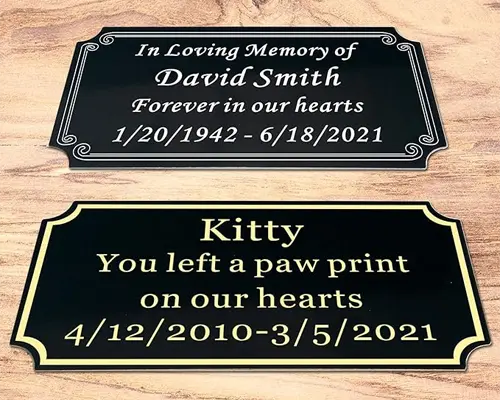

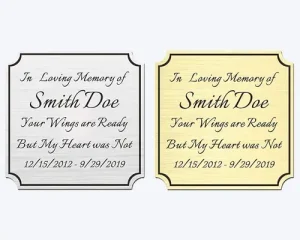

Etched nameplates are metal plates with text, graphics, or designs etched into their surface using chemical or laser processes. These plates work to show essential information about branding directions and compliance signage.

Key Benefits of Etched Nameplates

Durability: They come through tough outside climates without taking damage.

Customization: They meet precise product specifications and design requirements.

Clarity: Our precise manufacturing process makes text easy to understand.

Custom Etched Metal Nameplates

Why Customization Matters

Companies use customization tools to create nameplates that match their brand requirements and organizational requirements. The result is both practical and visually represents the company.

Specialized Nameplates Require Custom-Made Solutions

Logo and Branding Integration

- The addition of a company logo and branding creates a polished professional look while making your brand more recognisable.

- Our custom nameplates let you engrave text and graphics exactly as you need them.

- Businesses can add diverse details to their nameplates with features like text messages, QR codes, and serial number markings.

Durable Industrial Nameplates

- Industrial facilities depend heavily on nameplates that hold up under tough environments

- Industrial facilities place heavy demands on nameplates because they handle chemical contacts and endure high temperatures with scraping damage. Industrial nameplates remain useful for their expected service life in tough operating circumstances.

- The nameplate s need to handle both environmental stress and daily operational use.

- Nameplates need to stay strong against environmental damage from corrosion plus heat and sunlight. Companies select stainless steel and aluminum materials because they resist damage well.

Stainless Steel Nameplates

Advantages of Stainless Steel

- Stainless steel produces top-tier strength combined with corrosion protection while establishing an elegant finish that serves industries such as healthcare, aerospace, and manufacturing.

- Our custom product performs well throughout diverse business sectors.

- From machinery labels to safety signs, stainless steel nameplates are versatile and reliable.

Laser-Etched Nameplates

How Laser Etching Works

A strong laser tool helps make permanent clean lines onto metal without damage.

Benefits of Laser-Etched Nameplates

- High precision and detail.

- Our production team delivers results very fast.

- Stainless steel items endure scratching with little color loss.

Engraved vs. Etched Nameplates

Understanding the Difference

- Engraving takes away surface material, whereas etching makes chemical or laser changes to the substrate.

- You need to select the best method that works for your specific requirements.

- You should pick etching for detailed designs that need affordable production methods since engraving creates deeper cuts better for strong applications.

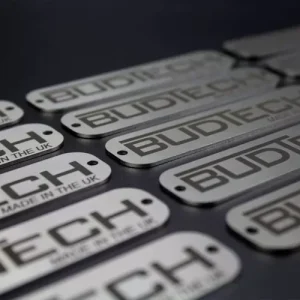

Metal Tags and Nameplates

Versatility of Metal Tags

Metal tags support nameplates by presenting coding details or working as single identification markers.

Use Cases for Metal Tags and Nameplates

Metal tags benefit organizations through product tracking systems for tools and materials plus standard operating procedure labels.

Chemical Etching for Nameplates

The Chemical Etching Process

- By covering metal surfaces with resist material, designers protect the areas they want to keep during acid treatments that remove unwanted parts.

- Ethical manufacturing leads to these benefits.

- These products become ideal for large production amounts.

- The process keeps the material surface intact without warping or bending.

Custom Nameplates for Machinery

Nameplate Engineering Boosts Object Identification

- Custom nameplates help you locate and monitor your machines while showing their correct use.

- The organization follows all industry safety rules.

- Machinery needs to display official data as demanded by law, and custom nameplates help deliver this information perfectly.

Aluminum Etched Nameplates

- Aluminum shows good performance for making nameplates

- The light weight and strong resistance against rust at an affordable price make aluminum work well in many situations.

- Common Applications

- Manufacturers of electronics aerospace and automotive use aluminum nameplates regularly.

Why choose TMN for metal-etched nameplates?

TMN Metal Parts Fabrication Factory stands out in metal-etched nameplates due to its advanced etching techniques, high-quality materials, and precise craftsmanship. The team creates durable weather-proof metal nameplates designed with customer preferences from premium materials like stainless steel, brass, and aluminum. Their different surface finishes, including brushed and polished, help them fit into aerospace electronics and automotive markets while improving product appearance and usage.

TMN provides outstanding product quality at affordable prices with quick deliveries combined with great customer support throughout the design and delivery process. Their versatility and commitment to sustainable practices, such as minimising waste during production, make TMN a trusted choice for durable and eco-friendly metal -etched nameplates.

Conclusion

Etched nameplates are invaluable assets for industries requiring durable, customizable, and high-quality identification solutions. The selection of proper naming material and etching methods helps companies produce nameplates that withstand their operations while making their brand more recognizable.