A custom vapor chamber is now essential for high-performance cooling in compact devices. Companies use custom vapor chamber manufacturing services to provide vapor chambers that are tailored to their exact specifications. With proper custom vapor chamber design for thermal management, they conduct heat quickly, minimizing thermal hotspots and improving the thermal stability of the system. Many OEMs also depend on custom vapor chamber fabrication for OEMs need the specific shape, thickness, and materials for their product. Of course, now with the affordable custom vapor chamber, even a small team can order one with really good thermal performance without increasing production cost at all.

What Is a Custom Vapor Chamber?

A custom vapor chamber is a high-performance heat spreader designed to handle high thermal loads in small electronics. This is achieved through a sealed chamber with a wick structure and working fluid that can pass heat rapidly over a large area. When companies hire custom vapor chamber manufacturing services, the manufacturers make units that meet the exact size, thickness, and performance specifications. This unique design of custom vapor chamber design for thermal management allows engineers to eliminate hot spots and stabilize the system. Most of the other OEMs also opt for custom vapor chamber fabrication for OEMs to get the device-specific shapes, yet a suitable, affordable custom vapor chamber solution remains available.

Custom Vapor Chamber Technology Explained

A custom vapor chamber that uses phase-change cooling to rapidly and uniformly spread heat over large or small areas. It allows modern electronics to operate cooler when pushed under a heavy load. Using a robust custom vapor chamber design for thermal management eliminates hot spots to maintain stability. Custom vapor chamber manufacturing services and custom vapor chamber fabrication for OEMs offer a way for companies to receive exact form without sacrificing affordable custom vapor chamber solutions.

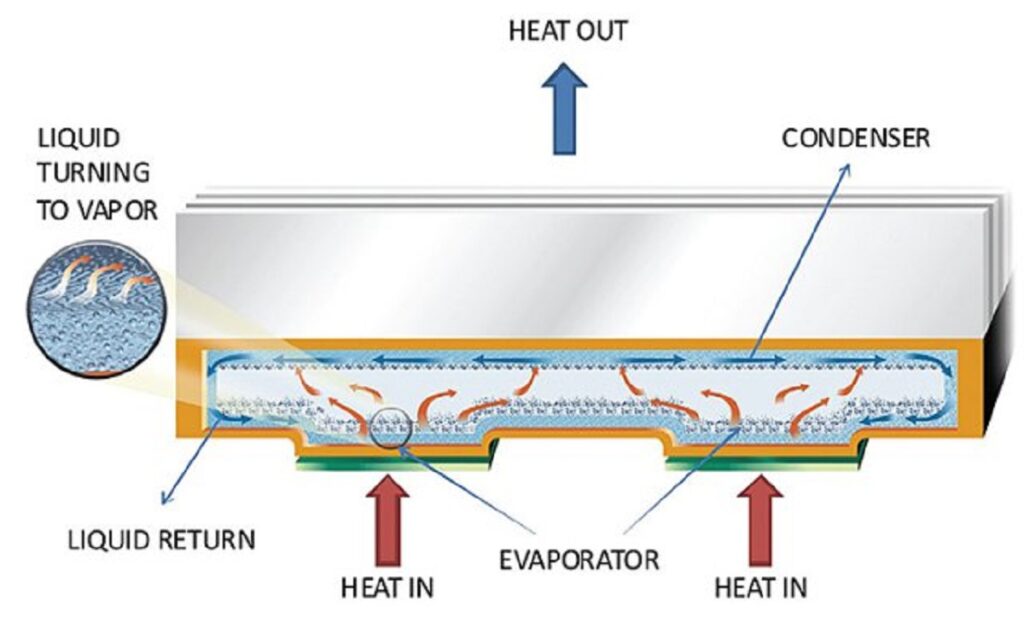

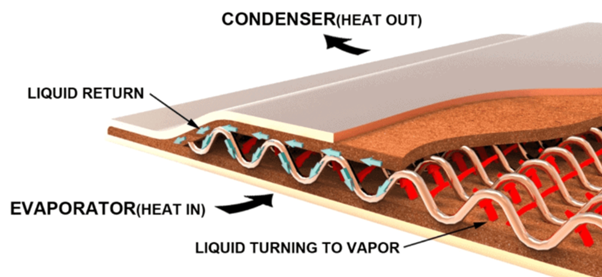

- Phase-Change Heat Transfer

A custom vapor chamber evaporates liquid to rapidly distribute the heat across the chamber. This makes it more efficient than solid metal heat spreaders. - Rapid Heat Distribution

The vapor inside creates heat evenly along the full surface of the plate. Thus, the custom vapor chamber reduces peak temperatures instantly. - Ultra-Thin Construction

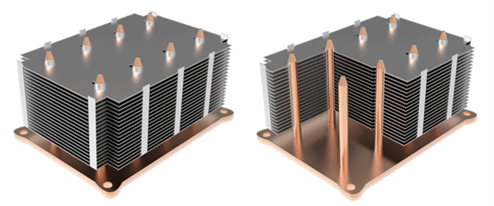

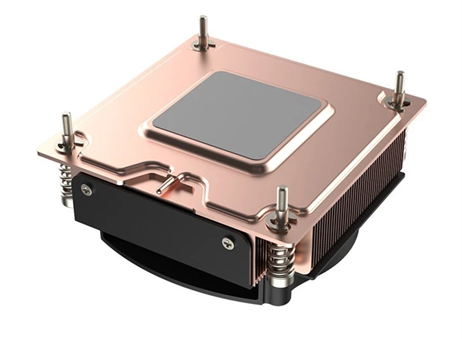

Chambers can be fabricated on a sub-millimeter scale due to expert custom vapor chamber fabrication for OEMs. This suits space-constrained devices while still delivering cooling performance. - Flexible Shape Engineering

At an advanced custom vapor chamber manufacturing service, however, chambers can be built in complex shapes. This has the support of laptops, servers, GPUs, and industrial systems. - Stable Thermal Performance

An effective custom vapor chamber design for thermal management prevents sudden temperature spikes. This safely keeps the components alive during prolonged usage. - High-Efficiency Wick Structure

The wick gives the condensed liquid back to the heat source. It allows the custom vapor chamber to run non-stop with no loss in efficiency. - Heavy Heat Load Support

It also has a custom vapor chamber that deals with high heat loads from CPUs, LEDs, and power modules. And that makes it perfect for future electronics. - Zero-Noise Cooling

The custom vapor chamber is the first of its kind that cools without the need for a fan, making it completely silent. As a result, failures of expendable moving parts are eradicated. - Long-Term Reliability

OEMs choose custom vapor chamber fabrication for OEMs because the sealed chambers do not change over the years. They are resistant to wear and corrosion and performance loss. - Cost-Optimized Production

This optimized foam provides an affordable custom vapor chamber through the use of improved material utilization, forming processes, and batch production by the manufacturer. This means low cost without compromising on quality.

How a Custom Vapor Chamber Works

A custom vapor chamber uses a fast phase-change cycle to move heat away from critical components. It uses a custom vapor chamber design for thermal management, both to cool the system under firing as well as to ensure stable output.

- Heat Induction & Evaporation: As heat flows into the custom vapor chamber, it is instantly transduced, enabling the vaporizing liquid to begin transporting heat energy.

- Snappy Vapor Propagation: Propagating across the vapor chamber surface, aided by the rapid custom vapor chamber manufacturing services to maximize performance, the vapor will migrate fast.

- Even Heat Spreading: The fluid goes equally over the silicon surface in order for the custom vapor chamber to get hot spots effectively drained.

- Condensation & Cooling: Working with its surface-mount custom vapor chamber fabrication for OEMs, the vapor condenses back into that liquid, as noted by the company.

- Liquid Return Path: The wick returns the liquid back to the heat input, forming a closed loop and is perfect for a very affordable custom vapor chamber-type application.

Custom Vapor Chamber Design and Engineering Considerations

Custom vapor chambers desperately need to be designed for long-term, reliable operation to avoid constant shifting behavior. A well-matched solution ensures stable temperatures, long component life, and high performance.

- Heat Load Calculations: This allows for much more accurate thermal mapping, ensuring the custom vapor chamber can handle the highest of highs without instability.

- Material Selection: Custom vapor chamber manufacturing services are available to select copper or hybrid alloys based on performance targets.

- Chamber Thickness & Shape: OEM teams use custom vapor chamber fabrication for OEMs to achieve ultra-thin or complex shapes that match device layouts.

- Wick Structure Optimization: Engineers optimize the density of the wick to allow for better liquid return and additionally tailor the wick design for a custom vapor chamber design for thermal management.

- Cost vs. Performance Balance: Brands can select an affordable custom vapor chamber with the aid of suppliers that optimize size, components, and volume for production.

Benefits of a Custom Vapor Chamber

A custom vapor chamber delivers effective and proven thermal management similar to the traditional cooling approaches. It provides a combination of performance, efficiency, and design flexibility, which is essential for modern electronics.

- Superior Heat Spreading: A custom vapor chamber spreads heat across an entire surface rather than allowing it to build up in one area.

- Compact, Thin Form Factor: Due to having an ultra-slim form factor, it can be attached along with a custom vapor chamber for installation in space-constrained enclosures

- High Heat Load Capacity: The chamber is able to handle large or automated thermal loads when hot processors, GPUs, or power electronics are used, thus avoiding overheating.

- Silent, Fan-free Operation: A custom vapor chamber can also cool your devices silently.

- Design Flexibility for OEMs: An affordable custom vapor chamber will fit in many devices. Quality vapor chambers, here you can find quality options via this link to vapor-chamber solutions.

Applications of Custom Vapor Chamber Technology

A custom vapor chamber can be one of the most widely employed thermal interfaces used for fast heat spreading and temperature stabilization for the devices. Various sectors accomplish consistent performance by utilizing a custom vapor chamber design for thermal management systems.

- High-Performance Laptops & Tablets: A custom vapor chamber manufacturing service for greater stability and reliability.

- Servers: Servers have a custom vapor chamber to manage dense heat loads and maintain stable performance in high-power environments, especially in data centers & cloud servers.

- LED Panels & Video Lights: LED systems for custom vapor chamber fabrication for OEMs for better control of heat & LED protection from being over-heated

- damage and increase the lifetime.

- Gaming Consoles & GPUs: A custom vapor chamber dissipates heat throughout GPUs and chips alike, delivering smoother performance in smaller gaming devices.

- 5G, AI & Industrial Electronics: Higher power level series typically select an affordable custom vapor chamber that can provide continuous high-power cooling.

How to Choose the Right Custom Vapor Chamber Solution

Custom vapor chambers are not one size fits all, though, and the best choice is modality dependent and based on the heat load from your device, space limitations, and cooling requirements. Perfectly tuned apparent temperatures will lead to a long life span of the components and high performance.

- Define Your Thermal Load: Start by understanding how much heat your device generates under peak use. This guides proper custom vapor chamber design for thermal management and ensures the chamber can handle real operating conditions.

- Check Size and Space Limits: Take measures for thickness, surface area, and available mounting room inside your device. The custom vapor chamber must be the same dimensions for effective uniform heat spread.

- Evaluate Material and Wick Options: Custom vapor chamber manufacturing service available in the market with recommendations on copper grades, wick density, and structural patterns. This improves the heat flow and long-term performance.

- Review OEM Compatibility Needs: OEM patterns often demand a customized bend or shaped design. Due to this, OEMs need to define a custom vapor chamber fabrication for OEMs for each model to get an appropriate fit without compromising device layout.

- Compare Cost and Performance: Price, wear life, and thermal results. A affordable custom vapor chamber should lead to high-quality cooling performance without compromising on quality or reliability.

How TMNetch Supports Custom Vapor Chamber Solutions

Every custom vapor chamber project receives the highest level of engineering and production support from TMNetch. They can assist OEMs and corporations in accomplishing precise cooling results with a combination of expert advice, rapid production, and guaranteed quality.

How TMNetch helps

- Specialized Manufacturing Support: TMNetch offers high-precision custom vapor chamber manufacturing services that ensure consistent quality and reliable heat performance.

- Engineering-Driven Design Assistance: The latter includes the development of a custom vapor chamber for thermal management by their experts in order to help the clients mitigate hot spots and improve thermal stability.

- OEM-Focused Fabrication: TMNetch has a custom vapor chamber fabrication for OEMs, so you can customize shapes, thickness, and sizes that are required for your product.

- Affordable Custom Options: They provide an affordable custom vapor chamber solution of industry-leading performance & reliability for start-ups and high-volume clients.

- End-to-End Technical Guidance: With TMNetch, your custom vapor chamber can be assisted in running the whole process line between the concept and the testing, securing the very best results whilst making minimal revisions.

FAQ

1: What makes a custom vapor chamber better than standard cooling options?

Custom vapor chamber runs hotter, has higher thermal stability, and has a more precise fit. Wider temperature range devices manage increased load with custom vapor chamber design thermal management through custom vapor chamber manufacturing services.

2: How do OEMs benefit from custom vapor chamber fabrication?

Custom vapor chamber fabrication for OEMS gives OEMS perfect shapes and thin profiles with repeated and dependable performance. This ensures every custom vapor chamber meets strict thermal needs with advanced custom vapor chamber manufacturing services.

3: Are affordable custom vapor chambers suitable for high-performance electronics?

Yes, an affordable custom vapor chamber still provides good cooling. Even low-cost chambers can meet the thermal requirements of demanding OEM applications with expert custom vapor chamber manufacturing services and intelligent custom vapor chamber design.

Conclusion

A custom vapor chamber is one of the most reliable cooling mechanisms in modern electronics. Custom vapor chamber manufacturing services provide companies with the stability they need to enjoy many more years of use from their devices. Good custom vapor chamber design for thermal management also dissipates heat more quickly and provides moving thermal mass to prevent component burnout. OEMs finalize their custom vapor chamber fabrication with the best fit and efficiency that the product desires. Nowadays, a custom vapor chamber is within reach of even a small business, thanks to trusted partners such as TMNetch. However, an adeptly designed custom vapor chamber never fails to offer better thermal performance.