As electronic devices become more compact and complex, controlling electromagnetic and radio frequency interference is essential. Custom EMI RFI shielding customized to a particular circuit layout, enclosure, and operating frequency. Custom solutions, contrasting with standard shielding parts, prove to be a more accurate, grounded, and EMI-compliant answer. To combat this prevalent challenge, custom EMI RFI shielding employs a collection of engineered, accessible materials and fabrication methods to help manufacturers reduce signal noise for these high-frequency systems, which, when left uncorrected, can lead to performance problems and reduced long-term reliability of advanced electronic systems.

What is Custom EMI RFI Shielding?

Custom EMI RFI Shielding and they are manufactured to inhibit the interference of unwanted electromagnetic and radio frequency radiation in applications. Rather than one-size-fits-all shields, precision metal etching for EMI RFI shielding works with specific PCB layouts at certain enclosures and operating frequencies. It results in better signal integrity and less noise, and it meets all regulations. Custom EMI RFI shielding solutions deliver consistent and repeatable performance in space-saving, high-density electronic systems used in industrial, automotive, medical, aerospace, and communication sectors, utilizing purpose-designed materials with defined manufacturing processes to suit those materials.

Custom EMI RFI Shielding Explained: When, Why, and How It Works

We install custom EMI RFI shielding if the standard shield types are not completely sufficient to satisfy your interference control needs on a complex or high-density electronics design. This enables it to tailor shielding geometry, materials and grounding for real operating conditions, thereby providing a more targeted defense. Such a line of attack promises the consistency of performance, compliance, and resilience in rigorous applications

How Custom EMI RFI Shielding Works in Practice

- When Interference Becomes Design-Critical

Standard shields fail to solve noise problems in cases such as high-speed signals, mixed frequencies, or compact layouts, and suffer from EMI RFI shielding that is custom and needs to be driven at scale. - Blocking and Containing Electromagnetic Energy

Shielding creates a conductive barrier that keeps EMI and RFI outside or inside specific areas of electronic zones. - Frequency-Specific Shielding Design

Custom EMI RFI shielding solutions are engineered to filter specific frequencies based on how electronic products operate and the compliance required. - Precision Fit to PCB and Enclosure Geometry

That’s because when you push the shield closely against the edges, there are no places for EMI to escape. - Grounding and Contact Optimization

Guiding proper grounding paths leads to a safer dissipation of energy from disturbances that leads to higher effectiveness of the shield. - Use of Advanced Fabrication Methods

Precise etching for custom EMI RFI fabrications, such as complex-shaped vents and fine details without mechanical stress. - Maintaining Thermal and Airflow Performance

Shield designs incorporate vent patterns that balance shield heat dissipation and EMI shielding. - Integration with Automated Assembly

SMT, reflow soldering and high volume are excellent with shielding. - Durability in Real-World Conditions

Vibration, temperature cycling and mechanical wear are all relatively well addressed with the custom EMI RFI shield fabrication - Optimizing Performance vs. Cost

Innovative designs of the custom emi rfi shielding cost effectively with long-term reliable performance and compliance.

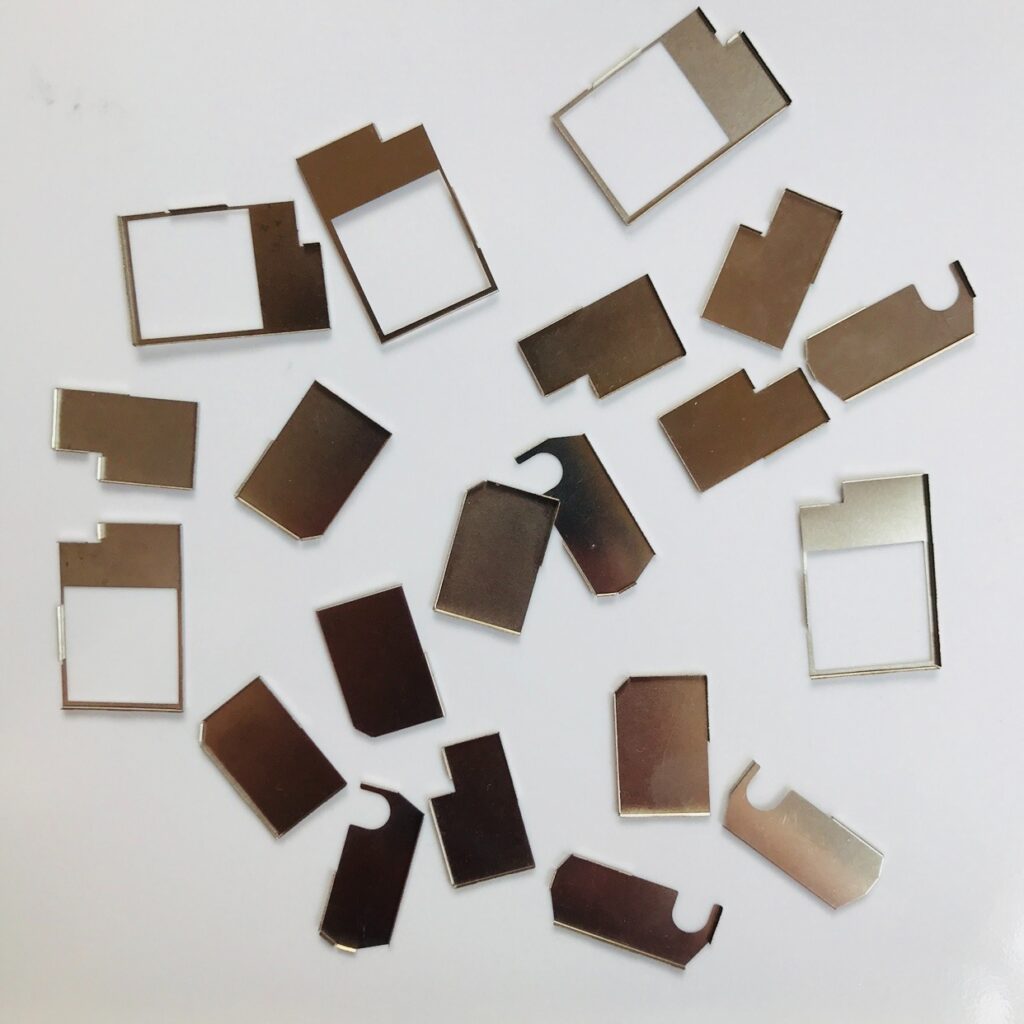

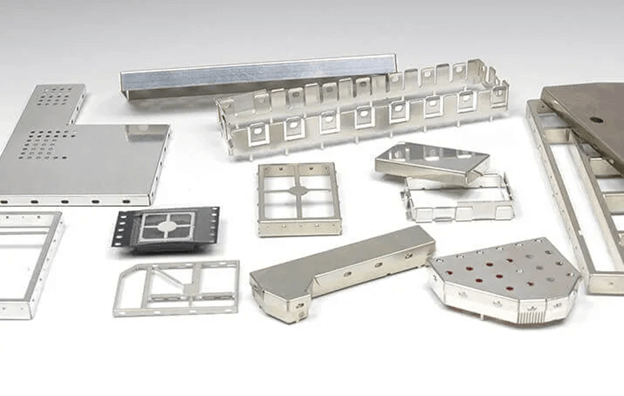

Types of Custom EMI RFI Shielding Solutions

Custom EMI RFI shielding products are designed in custom form to work with specific electronics and architecture, interference sources, and mechanical limitations. Selecting the proper type of EMI filter that will handle an efficient level of EMI suppression without detriment to performance, airflow, or manufacturing assembly process is a challenge in today’s electronic designs.

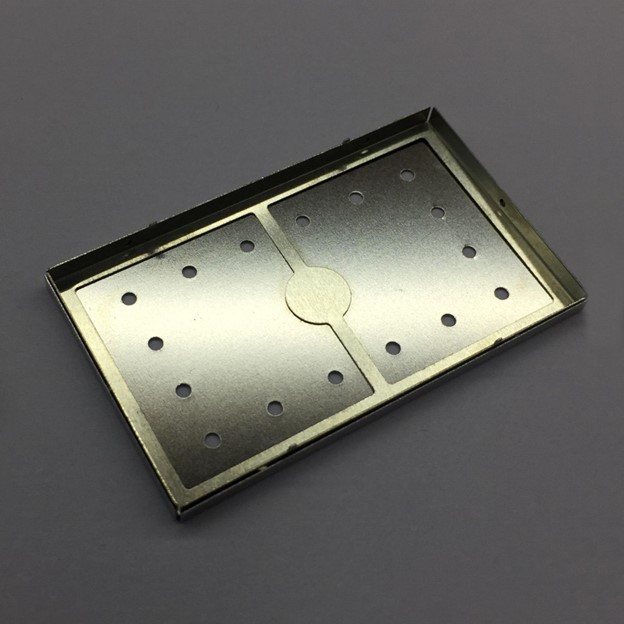

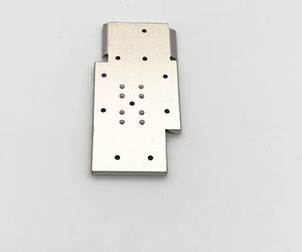

- Shielding Cans and Covers: Custom EMI RFI shielding solutions at the PCB level come in the form of metal cans, which help in isolating sensitive components from external and internal interference.

- Shielding Frames and Fences: These bespoke shielding solutions provide defined shielding zones on PCBs, making modular designs and reworkable assemblies more flexible.

- EMI Shielding Gaskets: Conductive gaskets function as custom EMI RFI shielding over seams and joints, providing continuity between enclosures and covers.

- Vented and Mesh Shields: These types of custom EMI RFI shielding designs will be designed to fit into your airflow specification and still provide your thermal management needs, along with effective EMI shielding.

- Integrated Enclosure Shielding: Integrated EMI RFI shielding solutions are integrated with the housing, reducing part counts, and identifying assembly challenges.

Benefits of Custom EMI RFI Shielding for Modern Applications

Custom EMI RFI shielding is fulfilling the demand for specific shields from electromagnetic forces required by most of the modern electronic designs. It allows better performance, compliance with regulations, and increased long-term reliability for small form-factor, high-speed devices among various industries.

Key benefits include the following:

- Improved Signal Integrity: In high frequencies, noise and crosstalk can easily make it impossible to transmit signals in mixed-signal circuits, custom EMI RFI shielding can reduce the interference.

- Design-Specific Protection: Compared to standard parts, custom shielding is designed for the specific PCB layouts and enclosures so that there are no points of leakage.

- Enhanced Regulatory Compliance

Good quality custom EMI RFI shielding solutions for products help them to accomplish EMI/RFI standards and test certificates in a much faster way. - Optimized Space and Weight: The use of custom designs allows thinner materials with precise geometry, offering compact, lightweight electronic assemblies.

- Long-Term Reliability: For high-performance applications, correctly formed custom EMI RFI shielding enhances durability under thermal, vibrational, and environmental load.

How to Choose the Right Custom EMI RFI Shielding Solution

It is crucial to understand your specific interference issues alongside mechanical limitations and production goals to select the right custom EMI RFI shielding. At this stage, the right decisions help achieve stable EMI performance, better manufacturing characteristics, and controlled costs throughout the lifecycle of the product.

- Identify the EMI/RFI Source and Frequency Range: Identify the source of RFI or EMI scourge and select a customized EMI RFI shield to suit the necessary frequency range.

- Go for the right shielding material: Select metals for their conductivity, strength, and compatibility with your custom EMI RFI shielding requirements.

- Ensure Accurate Mechanical Fit and Grounding: Shielding design that is aligned with the PCB layout and enclosures to create a good ground path and operation

- Check Manufacturing and Etching Capabilities: Work with suppliers who can provide the complexity needed for many custom high-performance EMI RFI shielding designs.

- Compare Total Cost and Scalability: Look at tooling, volume, and long-term custom EMI RFI shielding cost instead of concentrating on the first price, consider tooling costs and production volume, part cost in the long term.

Custom PCB-Level EMI/RFI Shielding Solutions by TMNetch

TMNetch offers application-oriented PCB-level low-frequency electromagnetic shielding suited for highly dense electronics. This solution is specifically targeting precision fit, effective EMI/RFI control, and scalable OEM manufacturing.

- Precision-Etched Shielding Cans: Custom-etched cans to match exact PCB layouts & component clearances

- Low-Profile Shielding Frames: Ultra-thin frames made to fit tight boards and packed-together assemblies.

- Consistency in Mass Production: Repeatable quality and close tolerances maintained through high-volume OEM runs.

- Material & Thickness Selection: Precision metal etching for custom EMI RFI shielding and gauges has been selected to create the best shielded yet thermally compatible solution.

- OEM Engineering Support: We work with you to determine and optimize the design for manufacturability from prototype verification to production.

FAQs

1. Why is EMI RFI shielded better in custom parts compared to standard parts?

Generic parts are not made to custom-layout EMI RFI shielding. Custom EMI RFI shielding services are a great way to add value in terms of interference control while also reducing the redesign risks for complex electronic systems.

2. How does the quality of fabrication influence EMI RFI shielding performance for custom EMI RFI shielding?

High-precision custom shielding is made possible by tight tolerances, right grounding, and Minimum leakages. With precision metal etching for custom EMI RFI shielding capabilities, it provides dependable EMI control in prototypes through production.

3. What factors influence custom EMI RFI shielding cost for OEMs?

Custom emi rfi shielding cost relies on the material cost and volume. When care is taken on the orientation of sensitive components and cables at the design phase, it frequently helps to avoid electromagnetic interference problems.

Conclusion

Custom EMI RFI shielding is still a key design component for modern electronic systems to prevent interference and signal loss. Expertly designed custom EMI RFI shielding solutions help manufacturers improve reliability, compliance, and performance over the life of the product. The ribs allow for a precise fit on OEM devices while simultaneously maintaining a consistent quality EMI RFI shield over large quantities demanded in these applications, with their scalable fabrication methods. When OEMs include well-designed shielding as early as possible, they can mitigate risk, ensure performance, and manage total custom emi rfi shielding cost over the lifetime of the product.