Chemical milling and chemical etching both remove metal with the help of a chemical solution, making them seem similar at first glance. The fundamental difference is in their application. Chemical milling removes material from thick substrates in order to either reduce weight or manufacture cavities. Whereas chemical etching cuts precise patterns through thin sheets of metal. While this seems simple, this difference is important for everything from the chemicals employed to the end results that can be anticipated.

We’ll explain each process step by step, compare the upsides and downsides of chemical milling vs etching.

Chemical Etching

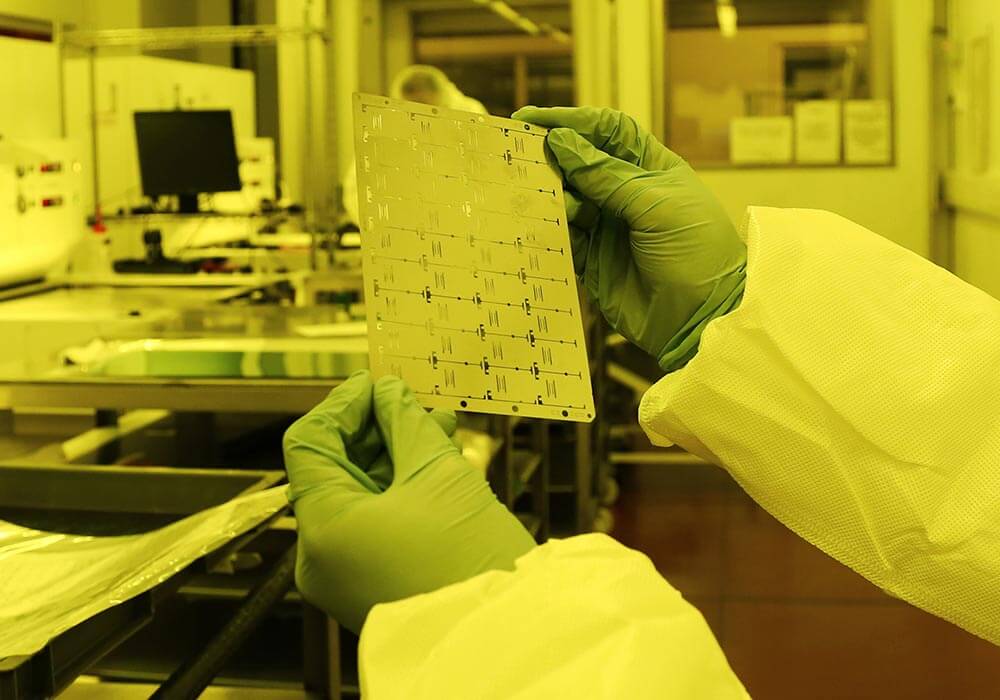

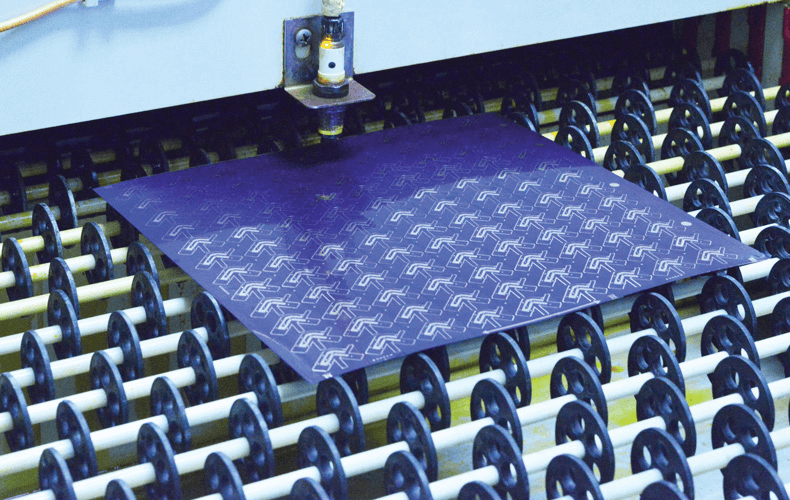

Chemical etching forms accurate designs and outlines in thin sheet metal. This method yields flat parts with tight tolerances and complex shapes. Etching results in a profile and detailed pattern rather than a cut-down or thinned version of chemical milling.

Process of Chemical Etching

Process-wise, the first step to beginning chemical etching is to create a digital design. Once the design is complete, it is masked onto photoresist-coated metal sheets by photolithography, or light masking.

The photoresist coating is then exposed. Then the prepared sheet is placed in an etching chamber where a chemical will come into contact with the exposed areas of metal. The etching solution will dissolve the metal at each of the openings, while the hardened photoresist will protect the areas that were covered.

Once the etching process is complete, the exposed areas will be fully penetrated, and the etchant will be neutralized.

Advantages

- Incredibly fine details down to 25 microns are achievable

- No mechanical stress or heat-affected zones

- Complex patterns are possible without tooling expense

- Works with a wide range of metals and alloys

Limitations

Here are limitations for chemical etching due to some technical constraints:

- Material thickness is typically limited to no greater than 1.5mm

- Aspect ratio limitations between thickness and detail size

- Development costs for the photolithography equipment and process

- Material waste for areas that do not require etch

Key Industries

Chemical etching services for industries that require precision thin components:

Electronics

Chemical etching is used for manufacturing flexible circuits, EMI shields, and connector contacts. The process can produce precise patterns in copper, stainless steel, and specialty alloys.

Medical

Medical companies make use of chemical etching for surgical blades, stents, and micro-components. As seen in other industries, the process can yield complex geometries, and these components must also possess biocompatible surface properties.

Aerospace

Aerospace suppliers utilize chemical etching for filters, gaskets, and lightweight structural components.

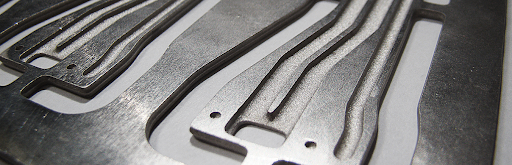

Chemical Milling

Chemical milling is a method to remove material from a metal surface by controlled chemical reactions. This subtractive manufacturing method can make precision cuts, create cavities, and give a weight reduction on many metals.

Process of Chemical Milling

Chemical milling begins with a thorough surface preparation of the substrate of the metal to remove oils, oxides, or contaminants. Then the technician applies a protective mask (or resist material) to the area of the part that is to remain untouched.

This masked part or component is lowered into a chemical bath that is appropriately acidic or basic for the type of metal. The solution dissolves areas of exposed metals, and the protected areas remain intact due to the resist.

Advantages

Some advantages of chemical milling include:

- Consistent removal of material across wide areas without tool marks

- No mechanical stress

- Complex shapes are feasible without expensive tooling

- Consistency of results independent of part size or shape

- Costs are manageable for prototyping or production

Limitations

Let’s look at some limitations of chemical milling:

- The process has limited control of depth, relative to mechanical machining

- Handling of chemicals and waste disposal will require safety precautions and processes

- Not all materials are suitable for chemical processes

Key Industries

Aerospace

Chemical milling aluminum components are leveraged in the aerospace sector to save weight on Aircraft components. This process allows for the removal of weight from key components such as structural wing members, Fuselage components, and parts of the engine.

Electronics

Companies in the electronics industry use chemical milling to create heat sinks and to remove weight from components.

Medical

Medical device companies are using a chemical milling process for manufacturing surgical instruments and the parts of biologic implants. In these parts, geometry and surface properties must be biocompatible, that are achieved using chemical milling.

Chemical Milling vs Etching

By knowing the difference between chemical milling vs etching, manufacturers can make better decisions regarding their processes.

Process

Chemical milling is focused on the controlled removal of material from an exposed surface for thickness reduction and cavity creation. Typically, the process removes material to specific depths, while also retaining the overall shape of the part. Chemical milling vs etching varies in that milling is used for thicker substrates, and milling removes variable amounts of material.

Purpose

The purpose of chemical milling is to reduce weight, relieve stress, and create recessed areas for an existing part. Chemical milling is typically used when metallurgically removing material is needed from complex geometries that cannot be accessed using machining tools.

Chemical etching is used to make very precise parts from flat sheets of material.

Precision

The precision of chemical milling vs etching depends on the specific application. Tolerances for chemical milling usually fall somewhere between ±0.05mm to ±0.25mm, depending on material and depth. However, the tolerances associated with chemical etching can be as tight as ±0.025mm.

TMNetch: Your Trusted Partner For Etching

TMNetch offers decades of experience in successfully executing projects for chemical etching across multiple industries. They have become one of the qualified vendors for Foxconn, Panasonic, Honeywell, and other large technology companies.

Here is why TMNetch is a good choice for photo etching projects:

- Rapid Prototyping: 6 hours from design file to prototype

- A photo etching company with a vast inventory of raw materials

- Precise: Tolerances as small as ±0.0005 inches

- Material Capabilities: They can process materials as thin as .01 mm, up to 3.0 mm thick, including stainless steel, brass, copper, aluminum, titanium, kovar, and nickel

Contact TMNetch for your custom projects.

FAQs About Chemical Milling vs Etching

How does chemical etching work?

Chemical etching employs photolithography to produce intricate patterns on metal sheets coated in photoresist. The resist is hardened using UV light and then used to chemically etch exposed metal with a solution. This creates precise, defined, cut, and/or pattern.

Chemical milling vs etching: Which is better?

Which process is “better” depends on what you need. Chemical milling is more suitable for the removal of materials in a thicker substrate, and applications involve weight reduction. Chemical etching is preferred for applications that require thin components with high precision geometries, complex patterns, and detailed features.

What to consider when choosing between chemical milling vs etching?

When looking at the cost and applicability of chemical milling vs. chemical etching, consider the thickness, precision, volume, and schedule of the production material.

Conclusion

When deciding between chemical milling vs etching, it’s critical to understand each process’s capabilities and limitations. Both have advantages over conventional machining processes for certain applications; however, determining the thickness of material, precision, and production needs. This guide will help you decide between chemical milling vs etching. Identify your project’s demands and specifications to determine the best process that meets your capabilities.