The Different Types of Chemical Etching Materials & Processes

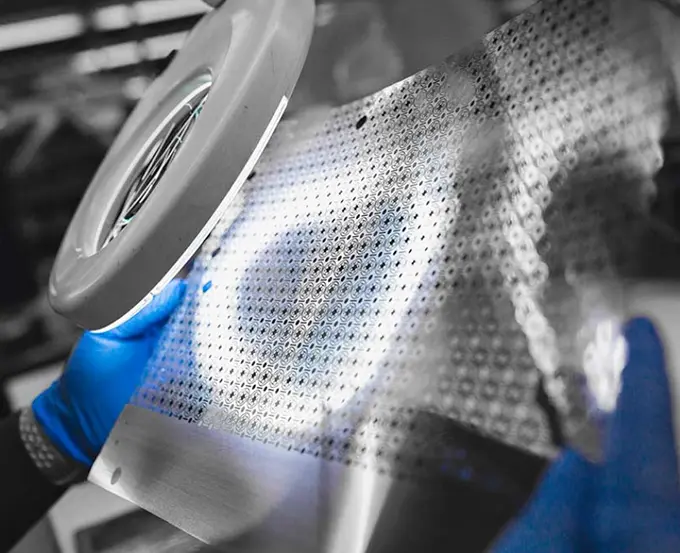

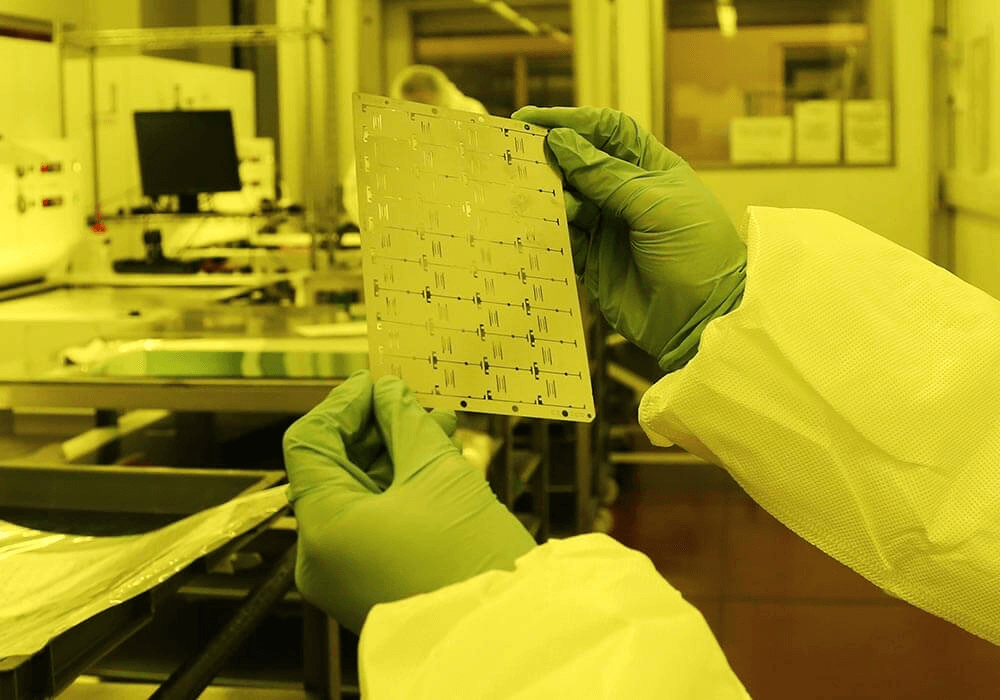

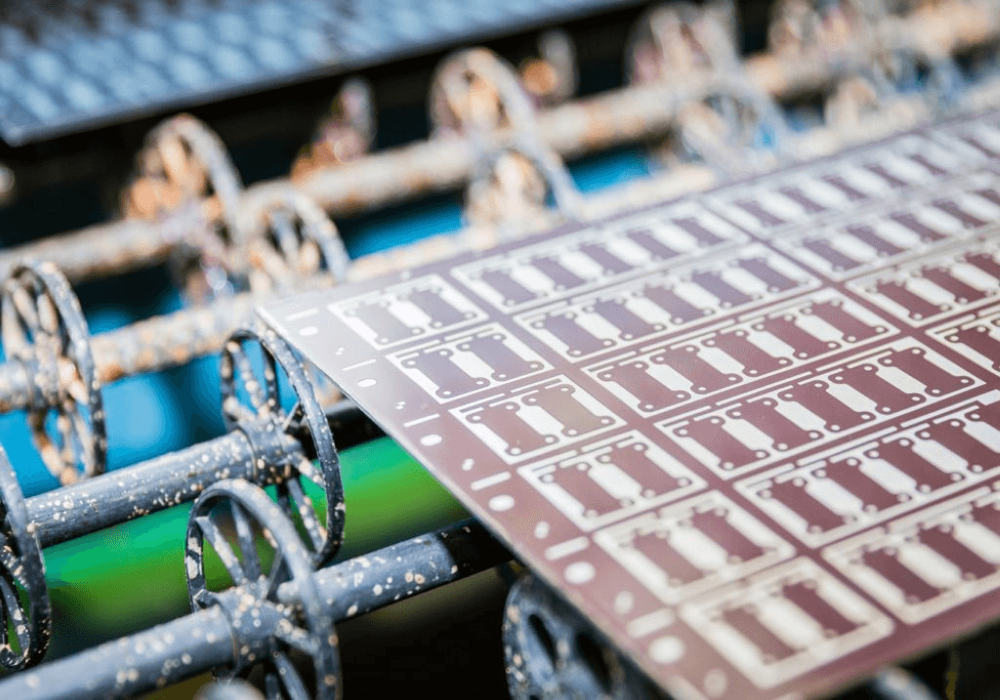

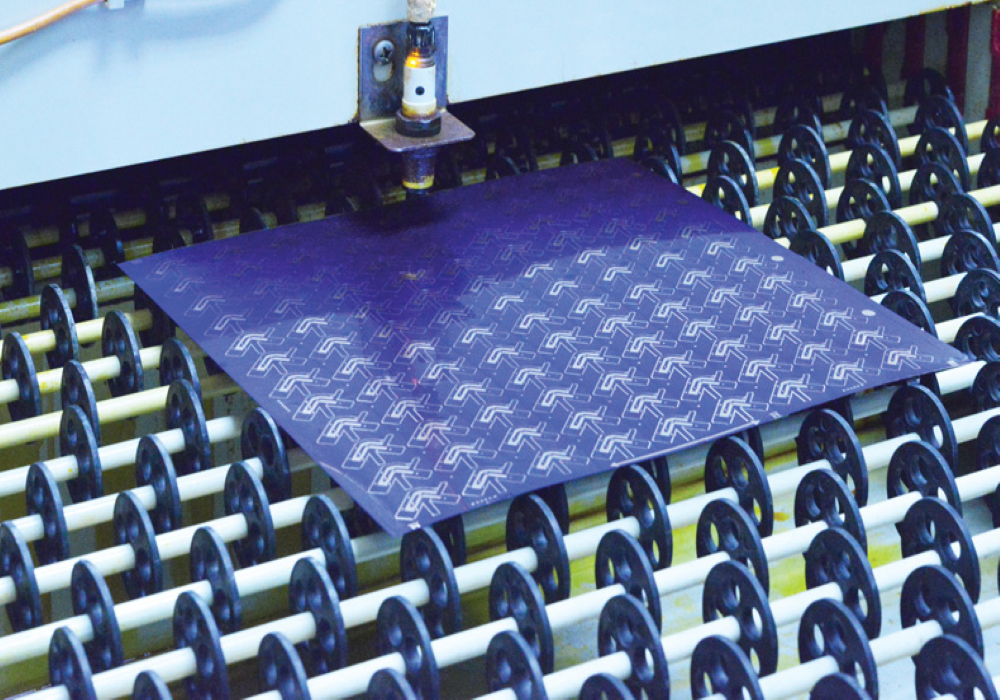

Chemical etching, also known as industrial etching or chemical milling, is a machining technology that works broadly the same way as the traditional melt working method but has many competitive advantages over it, one of which is its applicability of the widest ranges of materials such as metals and alloys – even those are hard […]

The Different Types of Chemical Etching Materials & Processes Read More »