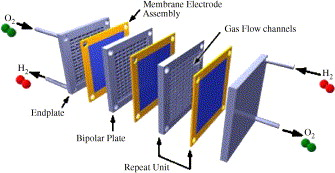

Bipolar plates are conductive dividers that link individual cells in a fuel cell stack. Each plate has flow channels used to control the flow of hydrogen and oxygen to the catalyst reaction sites and remove water and heat from the fuel cell. Fuel cell stacks may contain as many as hundreds of bipolar plates, typically between 200 to 400. The bipolar plate design also defines overall gas distribution in the stack and affects stack performance. Ultimately, what it comes down to for a bipolar plate is functionality; these plates must conduct electricity through the active area while keeping the gases separated.

What is a Bipolar Plate?

As the name “bi” conveys, the bipolar plate operates as a carrier plate or substrate for the two poles of the fuel cell. One end connects to the anode. Another end connects to the cathode of the adjacent cell.

- Two-sided functionality: What a bipolar plate fundamentally comes down to is this dual connectivity system.

- Structural component: Bipolar plates provide mechanical structural support to the entire fuel cell stack

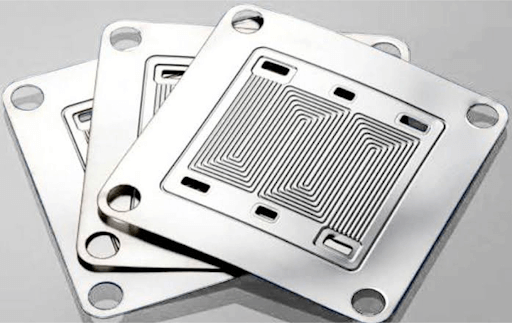

- Flow channel design: Each bipolar plate contains machined ridges or grooves that provide a distribution channel for gas.

The bipolar plate design determines how efficiently this electron transfer occurs.

Physical Structure

Bipolar graphite plates have thicknesses typically between 1-3 mm. The surfaces contain flow field patterns that are etched or molded into the material. These patterns guide hydrogen and oxygen to the reaction sites.

Function of Bipolar Plate

They perform a variety of functions: they direct the gases into and through the active layers, they separate the cells, they transport the electrical current produced, they also conduct excess water, and they keep the cell’s moisture content balanced. Each role occurs together during the operation.

Primary Roles

- Gas distribution: Bipolar plates route hydrogen to the anodes and oxygen to the cathodes using flow field patterns

- Electrical conduction: Bipolar plate provides the pathway for electrons from cell to cell

- Structural support: Bipolar plates provide mechanical structure to hold the stack together.

Secondary Roles

The bipolar plate design also manages water. Inside the stack, hydrogen flows toward the anode side of the cell, oxygen is brought to the cathode side of the cell, and water is generated as the only by-product of the reaction. One of the main purposes of the bipolar plate is to remove water so that flooding, which impacts fuel cell performance, does not occur.

Thermal Management

So, technically, the plates have three duties simultaneously: gas supply, cooling, and electrical connection in the fuel cell. Cooling channels exist to mitigate overheating during high-power operation.

Cell Separation

Think of the bipolar plate as a separator between the individual cells. It combines and separates individual fuel cells in series to create a fuel cell stack.

Common Bipolar Plate Materials

The two predominant materials used for bipolar plates are carbon and metal. Each material has unique benefits depending on the application.

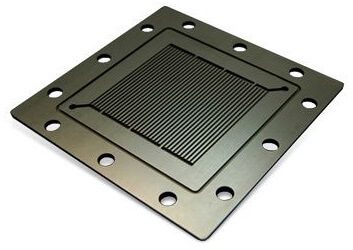

Metals

Metal bipolar plates dominate the passenger car market, as for this application, the stack form factor and energy density are critical.

- Stainless Steel: the most cost-effective option for metallic bipolar plates.

- Aluminum: Stainless steel, aluminum, and titanium are options that are more lightweight

- Titanium: the best performing metallic option

Compared to graphite options, metallic bipolar plates offer greater mechanical strength and electrical conductivity. Metallic bipolar plates can be made thinner than graphite bipolar plates.

Graphite

In heavy-duty PEM fuel cell applications, for example, trucks, trains, and ships, form factor and energy density of the fuel cell stack are not the primary concern, and the cost of the plates is paramount. Some additional materials we see used include stainless steel, titanium, or various unique specialty alloys.

Composites

Polymeric composites have shown their promise as an alternative to graphite and metallic bipolar plates. This is due to their cost-effectiveness, good corrosion resistance, lightweight, and flexibility.

Benefits of Bipolar Plate

- Heat removal: Bipolar plates help to remove the heat from the electrochemical reactions to limit overheating and keep the system at a safe temperature.

- Power density: Fuel cell efficiency, its power density, energy density with water and heat removal, is a function of BP’s performance during operation.

- Stack efficiency: Inside the stack, hydrogen flows toward the anode side of the cell, oxygen is brought to the cathode side of the cell, and water is generated as the only by-product of the reaction.

- Continuous operation: Properly designed bipolar plates disconnect fuel cells from thermal issues or water accumulation issues, which can impair performance.

Applications of Bipolar Plates

Bipolar plates are fundamental to advancing clean energy technologies, along with applications beyond one industry. Here are applications of bipolar plates:

Transportation

Bipolar plates are incorporated in hydrogen-powered vehicles and systems (cars, school buses, trains, etc.). For these applications, the plates should be:

- Lightweight, to maximize operational range

- Rugged, to endure continuous operation

- Reliable, to satisfy the mechanical requirements of PEM fuel cells

- PEM fuel cell bipolar material aids in increasing the driving range.

Industrial Hydrogen Production

Electrolyzers and other equipment that oxidize water into hydrogen and oxygen use plates that can handle hostile environments. Factors for plates in this category are:

- Resistance to corrosion in acidic and alkaline environments

- Long service life under sustained high loads

- Being consistent in operation when hydrogen is produced at scale

Stationary Power

Medical and data institutions (e.g., hospitals, data centers, and “run” factories) use stationary fuel cells like PEMFCs as backup or sometimes primary sources of power. In this sector, bipolar plates should have:

- Reliability in operation for longer durations

- Stable construction for extended runtimes

- Compatibility with unusual materials and polymer compounds for hybrid systems

- Emerging storage and applications

Research papers consider the use of bipolar plates with redox flow batteries and other storage technologies, further demonstrating that bipolar plates offer versatility beyond just fuel cells.

Bipolar plates are not niche items. Bipolar plates are core components that are essential to progress in transportation, renewable energy, and secure power supply.

TMNEtch Bipolar Plates

TMNetch provides leading commercial solutions of chemically etched metallic bipolar plates. They have been specializing in photochemical etching (PCE) since 2011, and are an ISO 9001:2015 certified facility. TMNetch is allied with more than 100 full-time employees, and the latest facilities, including four fully automated etching machines (20 meters long) and 19 additional automated production systems.

Their manufacturing capabilities give them a lot more scope and flexibility. They can manufacture complex parts and prototypes in a matter of days, typically 3 days.

Key Highlights

- Bind the choice of flow channel accuracy obtained by photochemical etching

- Manufacturing made in an ISO 9001:2015 certified facility

- 3-day rapid fabrication capabilities

- 100+ full-time employees with expertise

Their engineering team works directly with customers to optimize flow patterns, thickness, and appropriate materials. Please contact TMNEtch for the bipolar plate solutions that meet your exact requirements.

FAQs About Bipolar Plates

Which material is best for bipolar plates?

The best material for bipolar plates depends on the area of application. Metal plates work best for vehicles where space and weight are important. Graphite is a better material for maintaining low cost in heavy-duty applications such as trucks.

What manufacturing process is best for composite plates?

Two methods of manufacture are compression molding and injection molding. Both these methods are cost-effective and will keep the plates flexible and lower the risk of rust and corrosion damage.

How do bipolar plates affect fuel cell efficiency?

Bipolar plates control the efficiency of your fuel cell by allowing the heat and water to be taken away from the fuel cell plates. The better the bipolar plates, the more power you can make and reduce the likelihood that the fuel cells’ performance will suffer.

Conclusion

Bipolar plates determine the success or failure of fuel cells in practical applications. The bipolar plate design impacts the power output, durability, and end-use costs. The Bipolar plates transport reactant gases, transport the current from the membrane electrode assembly to the end plates, provide thermal and water management, and physically separate the individual cells to allow for stack assembly. The bipolar plate in fuel cell technology continues to redefine itself as hydrogen energy reaches mainstream use. Contact TMNEtch today for custom bipolar plates engineered to meet your precise specifications and performance needs.