Gasket vs Washer: Functions, Types, And Applications

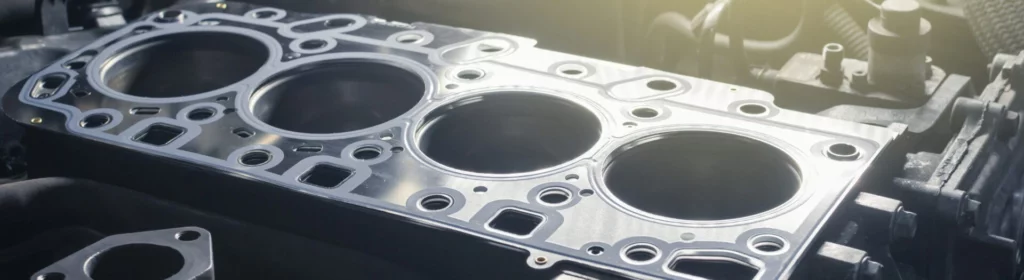

Washers and gaskets are commonly used across various industries. To the untrained eye, they may seem very similar. Although both are flat and round, they actually have very different functions. A gasket is designed to seal between two mating surfaces to avoid any type of leaks. It serves as a soft barrier that fills gaps. […]

Gasket vs Washer: Functions, Types, And Applications Read More »