Acid etching aluminum is a highly accurate process used to remove very small amounts of metal. TMNetch, one of the premier industrial acid etching aluminum providers in the industry, thrives on making perfect, intricate & functional aluminum parts for a range of industries such as aerospace, automotive, and electronics. The acid etching aluminum process is compulsary when a company needs its product to have a smooth, uniform finish. This will be able to achieve the look easily with the help of a professional B2B acid etching aluminum supplier.

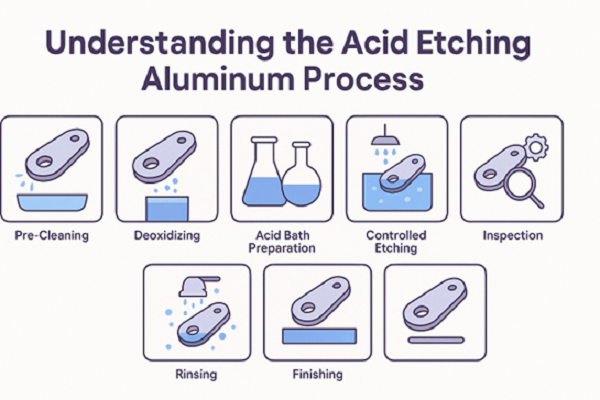

Understanding the Acid Etching Aluminum Process

The acid etching aluminum process is precise, being performed in stages, and it has become the method among industries across the world for attaining high quality surfaces on an aluminum substrate. It is a process consisting of a set of controlled chemical operations during which surface defects are eradicated, the adherence properties are improved, and the base material is prepared for coating or bonding. TMNetch is a reliable industrial acid etching aluminum service provider that applies modern practices and rigorous control to guarantee consistency in every acid etching aluminum process.

Step 1: Cleaning and Preparation

The aluminum parts will be thoroughly cleaned prior to etching to remove oil, grease, dust, and/or oxide films. You want a clean surface so the acid can have a reaction with nothing but metal. TMNetch utilizes ultrasonic baths and alkaline cleaners to thoroughly clean every component. This stage is crucial for the homogeneity of the acid etching aluminum process.

Step 2: Surface activation and degreasing

The aluminum is soaked in a deoxidizing wash to eliminate any remaining oxides, which may negatively affect etching quality. This result is beneficial to the ripening efficiency of the acid bath. A reputable B2B acid etching aluminum supplier like TMNetch makes sure this pre-treatment process results in higher bonding strength as well as better consistency.

Step 3: Chemical Bath Preparation

Then, a dedicated formula with hydrochloric or phosphoric acid is used as a bath. The temperature, concentration, and time are monitored to ensure no over-etch. Industrial acid etching aluminum service provider with an experienced team of designers and chemists, your next small or chemical etching aluminum bulk orders won’t be over-etched with aggressive chemicals.

Step 4: Controlled Acid Etching

The aluminum pieces are dipped in the acid bath for a predetermined time. The acid eats away a little bit of metal, improving the surface texture and removing impurities. Tedious reaction rates are constantly managed by well trained technical personnel so as to achieve an equal etching over the parts. TMNetch is a professional acid etching aluminum parts supplier for OEM brands, maintaining tight tolerances essential for the aerospace and automotive industries.

Step 5: Rinsing and Neutralization

Parts are deionized rinsed to remove chemicals after etching. The solution to neutralize (the reaction) is then introduced, for example, sodium bicarbonate. This process provides for stability and resistance to corrosion. Good rinsing is crucial for the life of the product from a B2B acid etching aluminum supplier.

Step 6: Surface finishing and drying

After neutralization treatment, the aluminum surfaces can be further subjected to finishing treatments such as anodizing, polishing, or coating for better performance. The etched portions are thereafter subjected to drying by means of clean air or hot-air ovens. TMNetch is a function improvement of post processing techniques and post processing service for chemical etching aluminum bulk order specialists.

Step 7: Check and Quality Control

Finally, every piece is magnified to ensure the exacting depth and finish demanded of our designer’s original sculpt. All parts quality control allows the same high standards required by genuine manufacturers to be achieved (or bettered in this case) during the acid etching aluminum process. The components are then packed and ready to be shipped to customers globally.

With these steps, acid etching aluminum process maintains uniformity, accuracy, and performance for a range of industrial purposes. This detailed process is why TMNetch still stands as an industrial acid etching aluminum service provider and an acid etching aluminum parts supplier for OEM brands.

Benefits of Acid Etching Aluminum for Industrial Use

The acid etching aluminum process is a type commonly used in the metal etching process. The uses of chemical etching are almost infinite, but they all have a common requirement for precision and quality. As a premier industrial acid etching aluminum service provider, TMNetch provides uniformity and accuracy not only for small orders but chemical etching aluminum bulk order as well to meet global OEM requirements. Here are some benefits of acid etching aluminum

- Excellent Surface Adhesive: Enhances paint, coater, and adhesive bonding to etched parts.

- Good Precision: It is able to achieve the complex pattern with high precision due to the high tolerance nature of acid etching aluminum.

- Oxidation Elemination: Oxides are being removed instantly which provides a good conductivity of the wire and hence a good welding can be performed.

- Consistent Surface Texture: As your trusted B2B acid etching aluminum supplier, TMNetch ensures all parts maintain consistent surface texture.

- Durability & Looks: Improved corrosion protection; better appearance

- Eco Friendly & Affordable: This environmentally-friendly usage of chemicals for each chemical etching aluminum bulk order makes it sustainably affordable.

- Scalable Manufacturing: TMNetch, an acid etching aluminum parts supplier for OEM brands, supports both prototypes and mass production.

These few major benefits make acid etching aluminum ideal for hard working predictable industries.

Applications of Acid Etching Aluminum

The acid etching aluminum process is widely applied across various industries due to its precision, versatility, and consistency.. Below are the main applications:

- Automotive Parts: Industrial acid etching aluminum service provider processes dashboards, fuel components, and trim panels to increase surface precision and longevity.

- Electronics: top quality PCB, Sensor, Desks for PCBs, Sensors and enclosures too, chemical etching aluminum bulk orders, incredible conductivity and detailed even when space is tight.

- Medical: The acid etching aluminium process allows for these medical instruments (including surgical and dental tools) to have a smooth, sterile and corrosion resistant surface finish.

- Construction and Design: Applicable to decorative materials (panel attachments on buildings/building interiors) as well as for metal with a defined pattern etching property that thermoelectrically limits reflectance, producing an aesthetic appearance.

- Defense and Aerospace Systems: The acid etching aluminum process ensures uniform surfaces for laptops, phones, and device casings with consistent quality.

- Consumer Electronics: Acid etching aluminum achieves to get a right surface for Al cover of laptops, mobiles and devices issues.

- OEM Manufacturing: As a worldwide acid etching aluminum parts manufacturer for OEM brands, TMNetch offers customized answers to industrial collections that need uniform surface processing.

These varied uses illustrate why TMNetch is still the best B2B acid etching aluminum supplier when it comes to accuracy and servicing for chemical etching aluminum bulk orders.

Why Choose TMNetch as Your B2B Acid Etching Aluminum Supplier

Through accuracy, scale, and experience, TMNetch “Everywhere You Need Perfect” is a very simple phrase to say. As a long-standing industrial acid etching aluminum service provider, it is well equipped to process chemical etching aluminum bulk orders and keeps the quality in control according to high standards articulated across industries. OEMs prefer to partner with TMNetch because:

- Professional supervision in each acid etching aluminum process step.

- Sophisticated chemical feed system for laboratory grade accuracy.

- We promise a timely delivery and B2B reliability.

- Support for customization of the product and etching of complex geometry.

FAQs

Q1. What chemicals are used for acid etching aluminum?

Acid etching aluminum kicks upstate provides for the use of either hydrochloric or phosphoric acid, which industrial acid etching aluminum service providers mix and control perfectly well, so that there will be no occurrence of anything getting scraped off but pure metal.

Q2. Is acid etching aluminum safe for use in industry?

Yes. When you hire a reputable B2B acid etching aluminum supplier to handle the job, it’s all done in accordance with safety and environmental regulations that ensure proper chemical handling and safe waste disposal.

Q3. How long does it take for acid etching of aluminum?

The acid etching of aluminum takes 10–30 minutes, including preparation and the actual “etching” time, with an experienced design team to achieve just the right surface roughness as well as press readiness.

Summary

The acid etching aluminum process transforms raw metal into high-performance components suitable for diverse industries. TMNetch, a professional B2B acid etching aluminum supplier, provides in lot sizes from small to mass production. And will continue to be the best industrial acid etching aluminum services provider around the world!