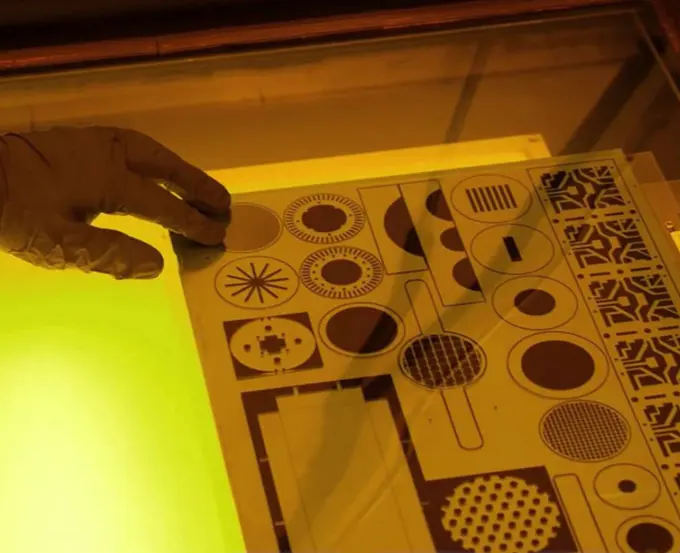

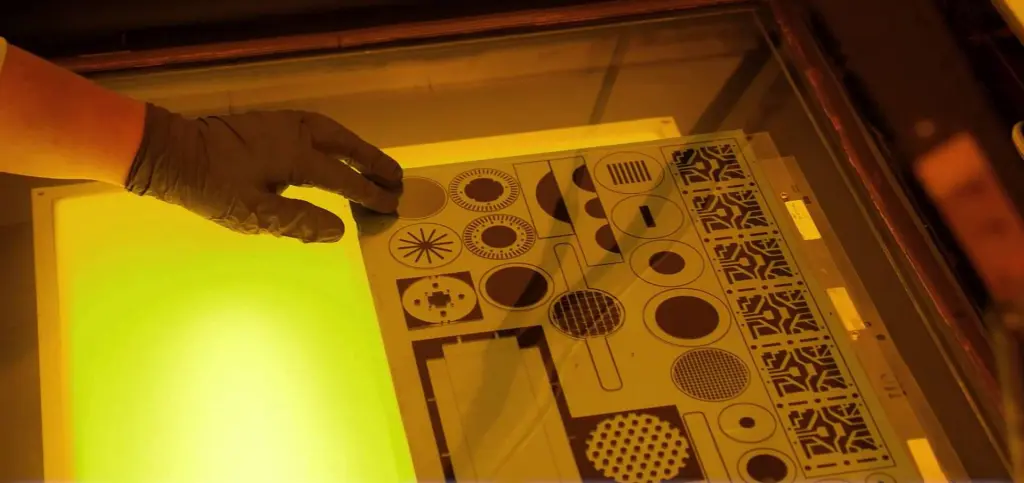

Chemical etching is one of the most popular subtractive manufacturing processes with high precision. It uses etching chemicals with regulated temperatures in order to remove materials accordingly and give life to metal parts with high precision. This method is quite effective with getting metal parts of any preferred shape.

What is the Difference Between Chemical Etching and Traditional Sheet Metal Machining

If you do a one-on-one comparison between chemical etching metal and traditional sheet metal machining, you will figure out that there are some prominent differences between them. Both these methods can be used to cut lines to a hard surface like metal. However, photo chemical etching is a completely chemical process. On the other hand, traditional sheet metal machining is pretty much a physical process.

The chemical etching suppliers will use acid solutions to etch lines. These acid solutions are quite effective when etching lines to a surface. It would leave behind detailed and intricate designs. However, the traditional method would engrave cuts directly to the surface. Sharp tools are being used to get the job done. One of the most popular metals used during both these processes is silver. You can deep dive and learn how to chemically etch metal. Then you will figure out how effective that process is.

What are the benefits of Chemical Etching Over Traditional Sheet Metal Machining?

The chemical etching process is highly effective when compared to traditional sheet metal machining process. Here are the main advantages that you can find in the chemical etching process.

Accurate

If you are concerned about accuracy, you should go ahead with the chemical etching process. If the design is complex, you should stick to it, without even taking a look at the traditional sheet metal machining process. That’s because you can ensure accuracy and keep the expenses low. Hence, you will end up getting maximum returns at the end of the day. This is the main reason behind the popularity of the PCB etching chemical process and other similar processes as well.

Burr free and Stress-free

During the chemical etching process, all the properties associated with the metal sheets would remain unaffected. That’s because a photo-resist mark would be created when you are applying all the design templates. Hence, it is possible to call this an effective and gentle technique. It would keep the original materials burr free and stress free. You cannot end up getting such results when it comes to stamping or punching.

Stamped, waterjet cut, and laser-cut parts are highly vulnerable to distortion. However, the chemical etched parts would not be subjected to any distortion. You will be able to experience the benefits that come along with zero degradation of materials.

Cost-effective

Chemical etching metal is a cost-effective process as well. It is possible for you to get even a complex design done without spending a fortune. The main reason why you can cut down expenses is that it takes lesser time. On the other hand, you will also be able to reduce the risk of errors. Therefore, you can get a better outcome with a relatively quick process. On top of that, it is possible to get numerous designs manufactured to a single sheet with this process.

Even the tooling that is used for chemical etching is a digital one. Hence, there is no need to go ahead and use difficult to adapt and expensive press tool assemblies. This is another reason why chemical etching can keep your expenses low.

Flexible

You will have the flexibility to adapt according to different component designs as you go ahead with the chemical etching process. You will have to chance to adapt economically and quickly. Hence, it is possible to get the volume production as well as the prototype within a period of just 24 hours.

Now you have a clear understanding of the benefits that come along with chemical etching. TMN tech is an ISO 9001:2015 certified etching factory, serving worldwide companies with custom precision metal parts to meet their needs. If you wish to experience the benefits of photo chemical etching, you will need to contact TMN. Then you can get your work done without encountering any challenges.