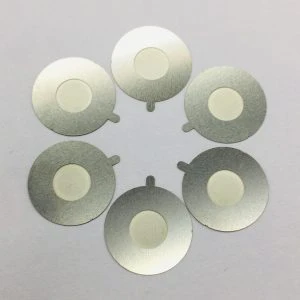

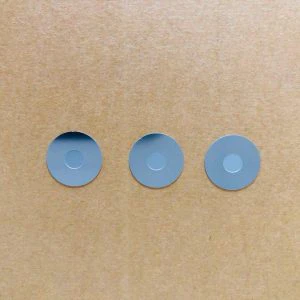

TMN is a professional custom metal washers manufacturer from China. This Electrode pad(sheet) is crafted using advanced photochemical etching technology, with an overall circular design and a precisely half-etched small circle in the center, making it both exquisite and durable. Thanks to the photochemical etching process, this product boasts extremely high precision with smooth, burr-free edges. Whether you require Electrode pad(sheet) or other metal washers, if you have any metal processing needs, feel free to contact us. We are happy to answer your questions and provide the best solutions.

Reasons to Choose TMN for Custom Metal Washers

Established in 2011, TMN has quickly grown into China’s leading photochemical etching company. We not only own a three-story etching building with a floor area of over 4,000 square meters but are also equipped with five fully automatic photochemical etching production lines, each 39 meters in length. This enables us to produce various complex metal washers with extremely high precision and efficiency to meet our customers' personalized needs.

Our team consists of over 100 experienced workers, professional engineers, and chemists, ensuring that every product meets the highest quality standards. To support diverse production needs, we have an independent large metal warehouse, stocking hundreds of types of metal raw materials. The primary materials include 300 series stainless steel, brass, copper, aluminum, titanium, Kovar alloy, and nickel, with thicknesses ranging from 0.01mm to 3.0mm.

TMN's products have been exported to many countries and regions around the world and are highly trusted by our customers. Our main markets include the United States, the United Kingdom, Germany, Switzerland, Australia, France, Hungary, Israel, Singapore, Vietnam, Malaysia, and Thailand. We also have a professional foreign trade team with extensive experience in arranging deliveries and preparing relevant documents and COC certificates to ensure smooth customs clearance and import inspection.

If you have a need for custom metal washers, don’t hesitate to contact us immediately. Only by reaching out to us can you truly experience our first-class customer service. No matter how challenging your project requirements are or the quantity you need, we will provide you with the best custom solutions.

Our Team And Factory

TMN Custom Metal Washers - Electrode pad(sheet) Production Process

At TMN, our custom Metal washers and Electrode pad(sheet) production process is efficient and seamless, offering you exceptional service from inquiry to delivery.

1. Inquiry and Requirement Confirmation:

First, you submit an inquiry to us. Our team will promptly contact you to confirm your specific requirements and drawing details, ensuring that all your needs are fully understood.

2. Material Preparation and Process Design:

After confirming your requirements, we select the appropriate metal materials from our own warehouse and design the most optimized processing plan based on your design.

3. Photochemical Etching Production:

Utilizing our advanced photochemical etching production line, your Electrode pad(sheet) will be quickly produced under strict process control, ensuring that each product meets high precision and quality standards.

4. Quality Inspection and Packaging:

Once production is complete, all products undergo rigorous quality checks to ensure they are free of defects. Then, we professionally package them according to your requirements, ensuring they remain intact during transportation.

5. Shipping and Document Preparation:

Finally, our foreign trade team will arrange the shipment and prepare the necessary customs clearance documents and COC certificates to ensure your order passes through customs smoothly and is delivered on time.

By choosing TMN, you will experience efficient and reliable custom service. From inquiry to delivery, we provide comprehensive support at every step.

What Are the Uses of Electrode pad(sheet)?

Electrode pad(sheet) is commonly used in fuel cells, electrolyzers, or batteries, primarily to ensure good contact between the electrode and other components, such as bipolar plates or current collectors. Its uses include:

Providing Uniform Pressure Distribution: Electrode pad(sheet) can provide uniform pressure distribution between the electrode and bipolar plate, preventing electrode damage or performance degradation caused by uneven pressure.

Reducing Contact Resistance: By ensuring tight contact between the electrode and other components, Electrode pad(sheet) can reduce contact resistance, thereby improving the overall efficiency of the system.

Protecting the Electrode: Electrode pad(sheet) also acts as a cushion, preventing mechanical stress damage to the electrode during operation.

Increasing Durability: Using Electrode pad(sheet) can extend the electrode's lifespan, reducing the likelihood of electrode failure due to material wear or other factors.

Get instant quote