Electromagnetic interference shielding is necessary for protecting and maintaining the normal operation of modern electronic systems away from unwanted electromagnetic noise. As devices shrink and power rises, interference problems multiply in consumer electronics, industrial equipment, and high‑precision systems. In this article, we will discuss the principle of precision metal etching for electromagnetic interference shielding, its importance and good practices followed by the manufacturers while using EMI shielding. Including considerations for material options, performance metrics, and real-world applications, tips which will be of interest to engineers, OEMs, and bundling teams looking for trusted shielding solutions.

Electromagnetic interference shielding and its importance

Electromagnetic interference shielding (EMI shielding) can block or reduce electromagnetic radiation from the surrounding environment that can interfere with the electronic circuits. It shields sensitive components from external noise affecting sensitive components, while also preventing internal signals from leaking out. Thus, the devices may not work, become inaccurate or fail compliance testing if you fail to shield them properly.

EMI shielding is not optional for regulated industries. Emission and immunity control are required by standards like FCC, CISPR, and IEC. That means shielding is an integral aspect of product design, not an afterthought.

Classification of Electromagnetic Interference

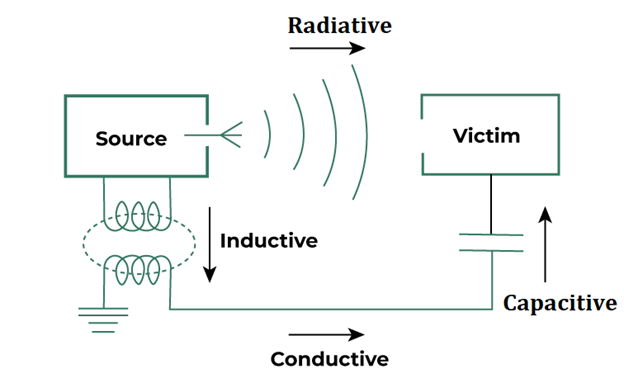

By understanding these classes of electromagnetic interference, engineers can choose the proper electromagnetic interference shielding method during design. EMI can be categorized according to its propagation and interaction with the electronics systems. They each require different materials and design concepts to perform stably.

1. Conducted Electromagnetic Interference

It involves unwanted electromagnetic energy travelling through physical conductors, like power lines, signal cables, and grounding paths; these give rise to conducted electromagnetic interference. Indirect EMI adds noise to electrical signals in connected devices.

Electromagnetic interference shielding solutions for electronic devices usually uses highly conductive material such as copper or aluminium to keep it in check inside of the objects are conducting an interference, limiting the conduct of interference. These materials safely reroute interference out to ground, enhancing system stability and reducing the distortion of the signal.

2. Radiated Electromagnetic Interference

Radiated EMI in which the energy is transmitted through the air, generally in the form of electromagnetic waves. Examples are wireless devices, electric motors, switching power supplies, and natural phenomena (such as lightning).

Electromagnetic interference shielding for the radiated EMI is typically implemented using enclosures, metal housings, or conductive coatings. These solutions are designed to absorb or reflect electromagnetic waves, preventing them from transferring to nearby sensitive electronics.

3. Capacitive Electromagnetic Interference

Explain Capacitive electromagnetic interference (EMI) and its cause. This is common in tightly packed electronic assemblies where the components are closely placed.

Electromagnetic interference shielding isolates components and reduces capacitive coupling using strong dielectric materials. By using proper spacing and insulation, it further decreases unwanted interference.

4. Magnetic Electromagnetic Interference

Magnetic electromagnetic interference results from one conductor inducing a current in a nearby conductor through the magnetic field. This type of EMI is especially difficult because a lot of common shielding materials will not be able to keep the magnetic fields out.

Mu-metal is often used for electromagnetic interference shielding for industrial equipment, because it is a high-permeability material that absorbs and diverts magnetic fields. Magnetic EMI derives its significance in MRI surroundings, as external magnetic interference can lead to image distortion or disable the operation of the system.

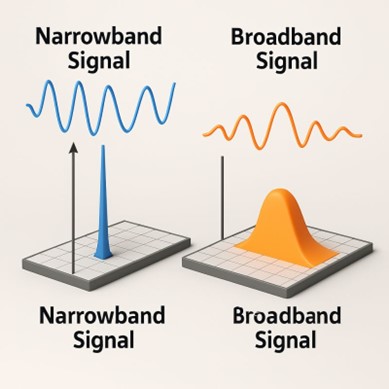

5. Narrow-Band Electromagnetic Interference

Narrow-band EMI takes place at particular frequencies normally associated with well-defined sources like oscillators, radio transmitters or clock signals. Such noise is easier to isolate from the audio because the frequency range will be limited.

Tailored electromagnetic interference shielding (EMI) designs can reflect or suppress the precise frequency range in need of being addressed, increasing efficacy by not applying additional, non-active material, and not incurring as much increased cost.

6. Broadband Electromagnetic Interference

There are many sources of broadband EMI, which cover a wide frequency range and generally interfere with several sources at the same time. It renders a single mitigation approach much less effective at controlling it.

Broadband noise requires strict electromagnetic interference shielding for industrial equipment strategies. These typically incorporate conductors, multiple layers, sufficient grounding and precision fabrication to ensure uniform performance.

EMI Shielding Materials and Performance Factors

Electromagnetic interference shielding materials directly impact performance, cost and manufacturability, each an important consideration in material selection. Materials have to obstruct, absorb, or bounce electromagnetic waves and be adapted to mechanical and thermal limitations.

Common electromagnetic interference shielding materials

- Copper: Great conductivity, very good shielding

- Aluminium: Lightweight and low cost for enclosures

- Stainless Steel: Modest shielding, high strength, and corrosion-resistance

- Nickel-silver Alloys: A compromise between conductivity and durability

- Conductive Coatings & Foils: Flexible choices for space-saving constructions

Electromagnetic interference shielding effectiveness is dependent on material thickness, conductivity, and surface continuity. Pay close attention to gaps or seams; even small ones can substantially reduce performance.

What Factors Affect Electromagnetic Interference Shielding Effectiveness

- Material conductivity and permeability

- Shield thickness and geometry

- Frequency range of interference

- Quality of grounding and bonding

- Manufacturing precision and tolerances

To achieve high electromagnetic interference shielding effectiveness means good material selection, but it also needs precise fabrication of the metallic fabric. But premium materials can be wasted on poor design.

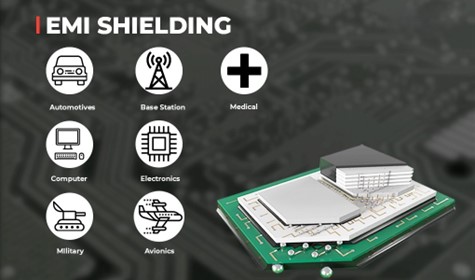

Electromagnetic Interference Shielding Solutions for Electronic Devices

The need for shielding in electronics requires a compromise between performance, size, weight and cost. Wireless signals, power sources, and adjacent components are always present and can interfere with consumer and commercial electronics.

Typical applications in electronic devices

- Smartphones and Tablets: RF shields for CPUs and antennas

- Medical Electronics: Sensor and diagnostic module shielding

- Telecom Equipment: EMI Frames and Shield Cans

- Automotive electronics: Control units, infotainment systems

Integrated design is the key solution to electromagnetic interference shielding for electronic devices. When engineers work with manufacturers from day one, it reduces risk for redesigns, as well as compliance with the rules.

Advantages of EMI shielding

Optimally designed precision metal etching for electromagnetic interference shielding has a direct bearing on performance, compliance and longevity between electronic and industrial systems. The benefits and limitations shown below illustrate the value added by shielding and the design trade-offs.

- Enhanced Signal Integrity: Maintaining signal transmission without distortion or interference when using appropriate electromagnetic interference shielding materials by increasing electromagnetic interference shielding effectiveness.

- Improved Product Reliability: Reduces surprise failures and long-term performance degradation.

- Longer Equipment Lifetime: Reduces use of electromagnetic stress on components, contributing to longer life.

- Ensure Regulatory Compliance: Provides support to help products reach EMC targets for electromagnetic interference shielding effectiveness against electromagnetic interference.

- Increased Safety and Thermal Stability: Prevents unintended coupling as well as heating in harsh conditions.

- Good Performance in High Density Electronics: Eliminates cross-talk effects between closely spaced devices.

How TMNetch Can Help You With The EMI Shielding!

TMNetch works with manufacturers to deliver precision stabilized production along with engineering driven assistance for continued and reliable electromagnetic interference shielding performance. Consistent quality across prototyping and scaled manufacturing enables customers to achieve their performance and compliance objectives.

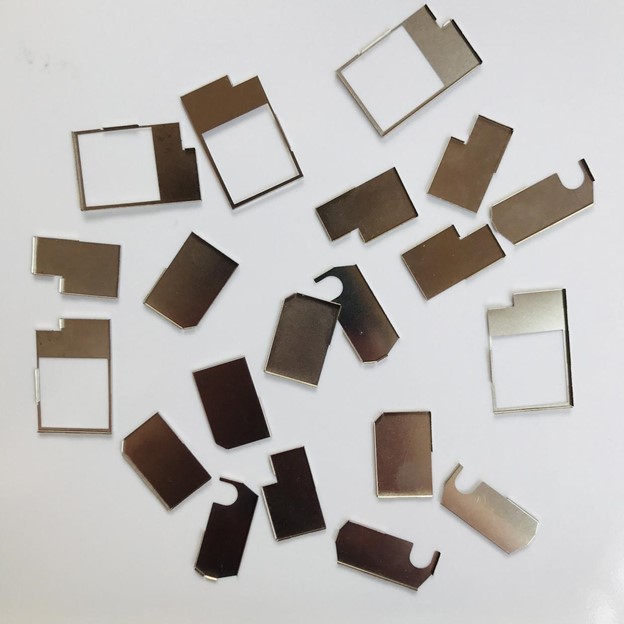

- Supports complex shielding designs using precision metal etching for electromagnetic interference shielding

- Stable repeatable results on thin metals and close tolerances

- Early manufacturing input to minimize re-design and compliance risk

- Supports scalable production for electronic and industrial applications

These practical solutions to shielding can be carried out in a manner that is efficient and scales with performance without impacting how manufacturers create the electronic devices.

FAQs

Q1. What is electromagnetic interference shielding effectiveness, and how is it determined?

The performance of electromagnetic interference shielding is influenced by surface conductivity, thickness, frequency range, grounding quality, and precision of the manufacturing process. Conversely, unless they are designed with exacting precision, even modest gaps and seams can dramatically degrade shielding performance.

Q2. Which electromagnetic interference shielding materials are best for high‑frequency applications?

Electromagnetic interference shielding materials typically consist of conductive or magnetic materials that provide a shielding effect by absorbing or reflecting them from outside the device. The high conductivity of copper and nickel-based alloys makes them common choices in high-frequency applications, while they also have good, consistent electromagnetic interference shielding effectiveness over a wide frequency range.

Q3. When should precision metal etching for EMI shields be used?

For instances where a thin, rather complex pattern is needed, precision metal etching for electromagnetic interference shielding is best, as is a burr-free edge; these features are ideal in RF shields, vent panels, and compact electronic assemblies.

Conclusion

Electromagnetic interference shielding is one of the building blocks of electronic and industrial system design in the modern world. Through the identification of appropriate electromagnetic interference shielding materials, maximization it’s effectiveness, and utilization of techniques such as precision metal etching for electromagnetic interference shielding, manufacturers are able to develop consistent, compliant products. Gradient software companies such as TMNetch facilitate this by supplying accurately tailored shielding components just right for real‑world performance requirements.