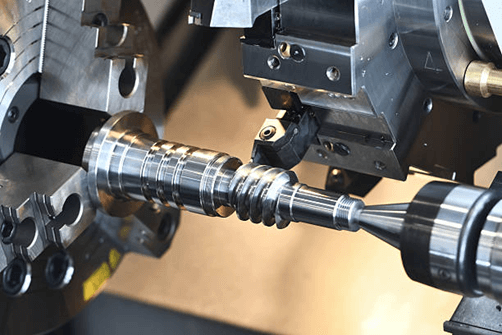

Manufacturing components that cannot deviate from a tight tolerance, the ones with exact dimensions that must perform repeatedly without failure, is precision metal machining. In industries such as automotive, machining is used to create reliable components. Precision metal machining for industrial parts happens even in high-pressure PG environments with cutting-edge CNC systems. These metal machining services help avoid the unintentional changes and variations in production. These manufacturers also have dedicated machines for OEM projects so that the designs are still retained. When supported by a high-precision CNC metal machining service, manufacturers enjoy the benefit of superior quality, repeatability, and efficiency with little deviation from technical and performance specifications.

What is Precision Metal Machining?

A precision metal machine is a piece of specialty machinery that is capable of creating precision-machined parts or other items in metal with very high accuracy and repeatability. They incorporate sophisticated CNC controls and deliver high-precision metal machining for tight tolerances and shapes. Today’s high-accuracy CNC metal machining services depend on these machines to create components for OEM and industrial applications. They are designed for accurate metal cutting for intricate shapes and precision metal machining of industrial parts, maintaining their quality, smooth finish after smooth finish, and long-lasting performance in the most demanding manufacturing applications.

Precision Metal Machine: The Backbone of Modern Manufacturing

Accuracy and precision in mass production metal machining are achievable with a strong precision metal machining base designed to offer high quality, repeatability, and efficiency during the machining method. These machines have the right features for target-industry segments with demand for high-precision metal cutting of performance-critical parts.

Key Roles of a Precision Metal Machine

- Delivers Consistent Accuracy

It is not the case of a machine that performs precision metal machining to exacting tolerances over lots of production runs. - Supports Complex Part Designs

These systems can assist in precision machining of metal for intricate shapes, including multi-axis contours and complex internal features. - Powers CNC-Driven Manufacturing

A high-precision CNC metal machining service relies on precision machines for automated, error-free machining operations. - Essential for Industrial Production

Durable industrial pieces require steel machining services that are able to work with metal efficiently and without a sturdy metal fabrication shop, you would have to count on manufacturers standing the test of time and jobsite effectiveness. - Optimized for OEM Manufacturing

Precision metal machining services for OEMs that use precision machines to meet specialized design specifications and volume requirements. - Reduces Material Waste

Metal machining controls the tool, resulting in less waste and, thereby, greater total material efficiency. - Improves Surface Finish Quality

These metal machining leads to finer finishes, and often times eliminates secondary finishing requirements. - Handles Diverse Metal Materials

A precision metal machine typically fits aluminum, steel, titanium, and maybe other alloys that are employable in precision metal machinery. - Enhances Production Speed

Automated cycles also increase the throughput in high-precision CNC metal machining service environments, without compromising on precision. - Ensures Long-Term Manufacturing Reliability

Consistent machining of precision metal parts ensures that their quality will not slip, and the system in which they are will offer stability over the long course of production

Applications of Precision Metal Machines Across Industries

Precision metal machines provide precision metal manufacturing in various industries where accuracy, repeatability, and material integrity are critical. They assist high-precision metal machining for standard components and challenging, high-performance components.

- Aerospace Manufacturing

Aerospace applications demand lightweight, highly multi-faceted, low-tolerance metal machining with robots able to achieve these over operating ranges for high-tolerance structural and engine components. - Automotive Industry

Precision Metal Machining for industrial parts automakers covers the machine shop with hardware metal machining to develop the engine component, transmission system, and safety-critical assembly. - Medical Device Production

Implants and other surgical tools also need exact specifications, which can only be provided through high-precision CNC metal machining service by medical manufacturers. - Electronics and Semiconductor Equipment

Precision metal machining is used for housings, heat sinks, and micro-components that require tight dimensional tolerances. - OEM and Industrial Equipment Manufacturing

Precision metal machining services for OEMs can provide reliable production of custom parts used in industrial machinery and automation systems.

Types of Precision Metal Machines

All kinds of precision metal machines are designed to support precision metal machining for different industries and materials, e.g., glass and plastic, along with a completely different set of tolerance requirements. Each one has a certain functionality, working together to produce high-precision metal machining for standard and complex applications alike.

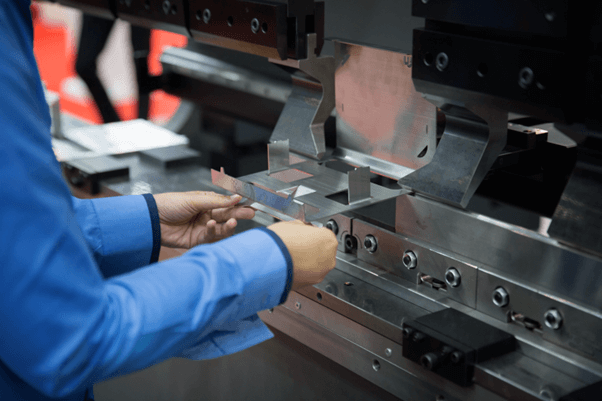

- CNC Milling Machines: CNC mills are used for precise surface cutting for industrial part machining applications and support precision metal machining for complex geometries.

- CNC Turning Machines (Lathes): These machines are used for round & cylindrical precision metal machining and are frequently utilized in metal machining services for OEM production.

- 5-Axis CNC Machines: 5-axis is suitable for CNC metal machining service and is ideal for more intricate shapes, allowing for tighter tolerances and fewer setups.

- Swiss-Type CNC Machines: Swiss machines work well for metal machining with excellent repeatability, because they were designed from the ground up to machine small, high-detail parts

- EDM Machines: EDM enables precision metal machining of complex geometries, particularly in the case of hard metals and thin-wall sections.

How to Choose the Right Precision Metal Machine

Choosing a precision metal machine is vital to obtain proven metal machining success across industrial & OEM applications. Choosing the right option can bring high-accuracy metal machining works, improving efficiency and long-term production value.

Key Factors to Consider

- Machining Accuracy Demand: The parts choose a high-precision metal machining plant with close tolerance, and the requirements are very strict for critical parts.

- Part Complexity and Geometry: If you need to work with complex geometric patterns, your best bet is a machine that can perform precision metal machining

- Use Application: Guide rails, band saw bases, machine tools, high-precision tools and parts for garden tool Steel that are difficult to approach distorted areas.

- OEM Manufacturing Compatible: Our oem metal machining and repeatable equipment are important.

- CNC Technology and Automation: The high-precision CNC metal machining service environment will call for sophisticated CNC control.

Why TMNetch Is a Trusted Source for Precision Metal Machining Solutions

TMNetch offers high-precision metal machining with engineering-driven solutions, new technology, and a rigorous quality assurance process. Their capabilities enable precision machining for OEM and industrial manufacturing requirements.

What Makes TMNetch Trusted

- Advanced CNC Capabilities: TMNetch provides a high-precision CNC metal machining service, which is designed for high accuracy, repeatability, and productivity.

- OEM-Focused Manufacturing Support: Their machining service for OEM parts maintains continuity from prototype to large production volumes.

- Expertise in Complex Components: TMNetch is dedicated to precision metal machining of industrial parts, structures, and super high design accuracy and dimension tolerance.

- Industrial-Grade Reliability: They perform metal machining of parts used by industrial and processing plants and even include parts that have to face the elements, yet cut and retain their bearings for life.

- Strict Quality and Process Control: Strict workflow and quality system & inspection standards for every precision metal machining product ensure no step is missing or neglected.

FAQs

1. What industries benefit most from precision metal machining?

Industry as diverse as aerospace, automotive, electronics, and heavy manufacturing relies on precision metal machining for industrial parts to maintain the low tolerances, high levels of quality, and work characteristics you need in high-stress operating environments

2. How does high-precision metal machining improve product quality?

High-precision metal machining not only gives the desired dimension to the components but also provides a smooth finish and process repeatability to the components, thus supporting advanced designs that are produced through the machining service.

3. Why do OEMs prefer precision metal machining services?

For OEM, on the other hand, precision metal machining services are often the go-to, as they can precisely and accurately hold tolerances on complex geometries between prototypes and mass-production steps and on small through large bulk runs while fulfilling metallurgical requirements across scales.

Conclusion

High-precision metal machining allows manufacturers to fabricate parts with tight tolerances, relatively high surface finish quality, and repeatable outcomes for critical applications. Precision metal machining services for OEMs can meet the requirements of intricate design and scalable production, such as precision metal machining for industrial components. TMNetch combines engineering expertise with a high-precision CNC metal machining service and is a trusted partner supplier for many manufacturers. As products become increasingly complex, precision metal machining will continue to be at the forefront of innovation, efficiency, and the road to sustainable manufacturing success from the factory floor to the supply chain, and complex geometries.