Aerospace metal fabrication is important for aircraft, spacecraft, and defense systems. Companies serve the aerospace sector by providing solutions for high-accuracy fabrication that comply with tight specifications and standards. The aerospace industry requires consistent quality, close tolerances, and predictable performance. Aerospace metal fabrication supports key aerospace uses, from ultra-light structural parts to heat‑resistant components. In this article, you will read about metal fabrication services for aerospace, the types of metal fabrication used in aerospace in detail, and how & why precision metal fabrication for the aerospace industry is essential to performance and safety. alt: Aerospace Metal Fabrication

What is Aerospace Metal Fabrication?

Aerospace metal fabrication involves metal cutting, forming, machining, and assembling parts for the aerospace world. This is different than general fabrication and operates under tight tolerances and certification standards [AS9100].

Metal fabrication companies serving aerospace now deal with modern alloys, specialized processes, safety, and weight reduction. These companies provide customized metal fabrication services for aerospace, for prototypes, and large-scale production.

Types of Aerospace Metal Fabrication

It only makes sense to understand the types of aerospace metal fabrication because that is how engineers can have the best metal fabrication process for a component. Different performance, strength, and weight needs throughout aerospace applications are supported by each method.

1. Sheet Metal Fabrication

One of the most common types of metal fabrication used in aerospace is sheet metal forming. This process makes use of cutting, bending, punching, and forming the thin sheet metal to precision aeronautical parts.

- For aircraft skins, fuselage panels, brackets, and enclosures

- Allows for a light construction, but helps keep strength

- Aluminum, stainless steel, and titanium alloy are compatible

- Typically followed by certified aerospace-focused metal manufacturing firms

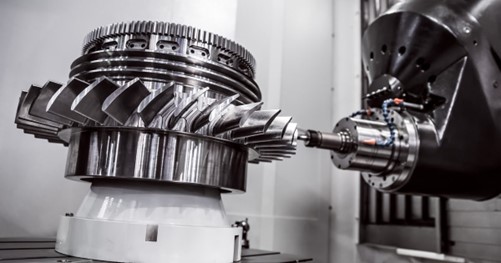

2. CNC Machining

CNC machining stands out as a cornerstone for high-precision metal fabrication for aerospace, creating intricately shaped components with precision tolerances that are extremely tight.

- deal for engine components, housings, mounts & fitment

- Delivers exceptional repeatability for high‑volume aerospace manufacturing

- Enables multi‑axis machining of complex shapes

- Key function within advanced precision metal services for aerospace

3. Welding and Assembly

Because many complex aerospace metal fabrication solutions will require reliable joints between assembly components, work done to specialize in welding and assembly processes will prove crucial.

- TIG for laser and electron beam welding, aerospace-grade strength

- For components such as frames, ducts, fuel systems, and structural supports

- Enrolls certified aerospace welders and places them in certified environments

- Commonly used in tandem with additional types of metal fabrication used in aerospace

4. Chemical Etching and Precision Etching

For closer shaped thin components in low volume, the aerospace industry is utilizing chemical and photochemical etching technology in precision metal fabrication for the aerospace industry.

- To remove burrs with no mechanical stress.

- Radiators, shims, heat exchangers, filters, shield parts

- Allows complex designs that cannot be done by machining

- These have become a regular feature of advanced aerospace metal fabrication companies like TMNetch over the years

5. Forming and Bending Processes

Aerospace metal fabrication continues with metal forming & metal bending, including the types of aerospace metal fabrication with curved, contoured aerospace parts.

- Employed as airframe structures and internal supports

- Maintains material integrity during shaping

- Minimize the number of welded joints required

- Typical of integrated aerospace metal fabrication

All these types of metal fabrication used in aerospace cater to unique performance targets, so accompanying material specifications and production quantities vary accordingly. Selecting the appropriate technique enhances efficiency, safety, and long‑term reliability.

The Importance of Precision Metal Fabrication for The Aerospace Industry

In aerospace manufacturing, accuracy is of crucial importance. Aerospace parts need to be precise to not only perform but also maintain safety while flying. Metal fabrication for aerospace guarantees parts are produced to exact requirements for performance, safety, and to endure changes in flight conditions over long periods of time. The following are the major reasons as to why precision metal fabrication for the aerospace industry is important:

- Flight Safety and Reliability: Metal fabrication delivers more accurate parts that are likely to be more reliable and less likely to fail during flight.

- Tight Tolerance Needs: Aerospace metal fabrication services provide micron‑level tolerances needed for advanced metal fabrication solutions for aerospace.

- Efficacy in Weight Reduction: Precision in aerospace fabrication allows for the removal of excess material while maintaining strength.

- Performance in Extreme Conditions: Precision metal fabrication for the aerospace industry guarantees performance in extreme conditions due to heat and vibration.

- Compliance with Regulations: Certified aerospace fabrication assists in meeting AS9100 and aerospace standards.

- Less Scrap and Rework: With less error and waste, complex aerospace metal fabrication solutions with precision are able to facilitate designs effectively.

For precision metal fabrication for the aerospace industry, manufacturers can increase the efficiency, safety, and consistency of their products throughout a complex aerospace metal fabrication project.

Complex Aerospace Metal Fabrication Solutions

This is because most modern aerospace systems demand accurate and high-performance aerospace metal fabrication solutions which have combined multiple processes within a single workflow. It is used in more advanced designs applied in aircraft engines, satellites, and UAVs; these solutions are also within your reach.

- Multi‑layer heat exchangers

- Thin‑wall structural components

- Custom flow plates and shields

These require a close synergy between the design engineers and the metal fabrication companies serving aerospace. Aerospace metal fabrication services under one roof reduce lead times and help make better designs.

Advanced metal fabrication solutions for aerospace are delivered by TMNetch by combining etching, forming, and secondary finishes. Such an approach enables fast prototyping and scalable production for aerospace customers.

Advantages of Aerospace Metal Fabrication Services

There are many benefits as to why manufacturers and suppliers opt for professional fabrication services. Here is the list of the most useful benefits of precision metal services for aerospace:

- Consistent Manufacturing Quality: The focused processes of aerospace metal fabrication can be even more standardized, yielding repeatable quality in each production run of parts.

- Waste Minimization and Material Efficiency: A proficient aerospace fabrication can also ensure that scrap is minimized and all parts have the required strength and performance.

- Harnessing Artificial Processes: Regulating artificial processes to make safety-critical aerospace parts more resilient. Link to paper

- Rapid Production Cycles: Modern companies offer integrated workflows, lower lead times, and delays.

- Support Complexity: With these more advanced complex metal manufacturing for aerospace components, your designs can feature complex geometries and structures that are more lightweight.

- Adherending To Aerospace Standards: Certified metal fabrication services for aerospace help manufacturers to comply with AS9100 and regulatory requirements.

Custom aerospace fabrication helps clients at all stages of design to final production, and companies like TMNetch offer such services.

How to Select a Quality Aerospace Metal Fabrication Company

Choosing good metal fabrication companies serving the aerospace industry ensures long-term rewards. Not every fabricator is aerospace‑grade. Here are some tips to consider when deciding between companies:

- Industry certifications (AS9100, ISO)

- Local experience with aerospace metal fabrication projects

- Ability to provide complex solutions

- Extensive experience in fabrication for the aerospace industry

TMNetch provides advanced etching-based solutions, fast turnaround, and engineering support, which puts them above your average metal component manufacturers for aerospace.

FAQs

Q1. How is aerospace metal fabrication used?

Aerospace metal fabrication is the process of producing structural, mechanical, or even functional aircraft, spacecraft, and defense system parts. Responding to the global aviation industry, manufacturers offer certified aerospace metal fabrication services to produce lightweight and durable aerospace components that conform to very strict aerospace standards for safety and performance.

Q2. How do aerospace metal fabrication companies ensure precision?

Process control, automation using CNC machines, and high precision inspection instruments are critical for high-grade aerospace metal fabrication facilities. An approach like this strengthens precision metal fabrication for aerospace, ensuring that parts are within the limits of dimension and compliance.

Q3. What separates aerospace metal fabrication from standard fabrication?

Aerospace metal fabrication has its own unique requirements, notably in the areas of tracking materials, strict quality controls, and compliance standards. Complex aerospace metal fabrication solutions need to not only perform under the highest of specifications, but also do so reliably under harsh conditions, including extreme heat, pressure, and vibration, unlike general fabrication.

Conclusion

The core of modern aerospace production, from structural components to precision-engineered parts, the industry relies on reputable metal component manufacturers for aerospace and sophisticated metal fabrication services for aerospace. Through the different types of aerospace metal fabrication and their significance to precision metal fabrication for the aerospace industry, the aerospace industry allows manufacturers to attain high performance and reliability. TMNetch delivers bespoke aerospace component solutions with innovation as the backbone behind it all, while continuing to support aerospace innovation with scalable, accurate, and complex aerospace metal fabrication solutions, all of which are tailored towards the needs of demanding industries.