Metal mesh filter material selection is crucial to ensure performance, durability, and cost-effectiveness. With a range of choices from stainless steel to nickel metal alloys, industries look up to the metal mesh filter material manufacturers like TMNetch, which provides industrial metal mesh filter material as well as custom metal mesh filter solutions. This article goes through the metal mesh filter material types, the characteristics, advantages and disadvantages, and the main applications of the most popular metal mesh filter material list.

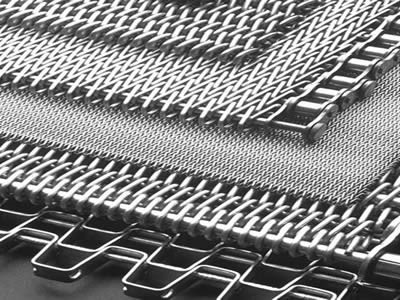

1. Stainless Steel

Features:

- The metal mesh filter material has the most widespread applications among metal mesh filter material manufacturers.

- More corrosion-resistant grades like 304 and 316 grades

- Uses of industrial metal mesh filter material are strong, durable, and heat-resistant.

Pros:

- Great corrosion and chemical resistance.

- Handles high temperature and pressure.

- Washable and reusable, reducing cost.

Cons:

- Heavier than alternatives like aluminum.

- Higher cost than simple steels

Best For:

Durable and corrosion-resistant industrial metal mesh filter material in the chemical, food, and beverage industries.

2. Aluminum

Features:

- Thin metal mesh filter material, excellent for custom metal mesh filter designs

- Industrial metal mesh filter material, with good thermal and electrical conductivity.

- Well corrosion-resistant metal mesh filter material manufacturers can be moulded into different shapes.

Pros:

- Lower cost and weight.

- Easy to handle and transport.

- Ventilate and Ornamental Purpose Usage

Cons:

- Weaker mechanical strength.

- Does not withstand exposure to strong chemicals or excessive heat

Best For:

Low-weight custom metal mesh filter designs for light-duty industrial, ventilation, and architectural applications

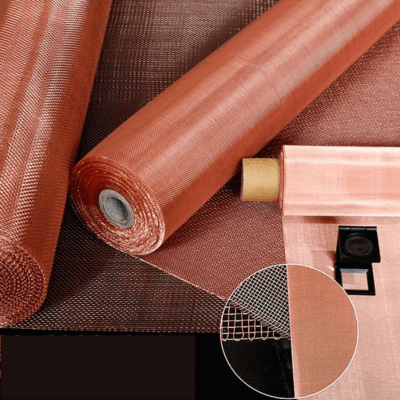

3. Copper

Features:

- Workable metallic mesh filter substance of very good conductivity mesh filter substance

- It has natural antimicrobial properties that would make it highly useful as an industrial metal mesh filter material.

- Red finish is good for custom metal mesh filter applications.

Pros:

- Excellent electrical and thermal conductivity.

- Well-suited for delicate custom mesh forming.

- Antimicrobial surface in some applications.

Cons:

- Costly and fluffy, it wears out fast.

- Oxidizes easily, requiring frequent maintenance.

Best For:

Custom metal mesh filter solutions, including EMI/RFI shielding & decorative mesh, as well as specialty filtration where conductivity is required.

4. Brass

Features:

- Copper-zinc alloyed metal in metal mesh filter materials

- Pleasant gold finish, more appropriate to custom-tailor-made filter-type metal mesh constructions.

- For industrial metal mesh filter material is stronger and has better wear resistance compared with pure copper.

Pros:

- A decent option for corrosion resistance in mild environments.

- Still useful and malleable for ornamental sieves.

- These are provided by most metal mesh filter material manufacturers.

Cons:

- Discolors over time.

- Susceptible to corrosion compared with stainless steel

Best For:

Where appearance matters in decorative and architectural filters, light industrial applications, and custom metal mesh filter designs.

5. Bronze / Phosphor Bronze

Features:

- Copper-tin alloy is included in the metal mesh filter material list.

- Durability and corrosion resistance, Phosphor bronze is one of the industrial metal mesh filter material.

- Applicable to custom metal mesh filter applications for outdoor and marine uses by metal mesh filter material manufacturers.

Pros:

- Better wear resistance than brass.

- For outdoor and marine environments

- Stable appearance compared to brass.

Cons:

- More expensive.

- Heavier than aluminum.

Best For:

This is an industrial metal mesh filter material used for marine, aquatic, and wastewater environments.

6. Nickel & Nickel Alloys

Features:

- Metal mesh filter material list media include Monel, Inconel, and Hastelloy.

- Custom-made heavy-duty industrial metal mesh filter material.

- It is manufactured from specialized metal mesh filter material.

Pros:

- Amazing Acid and Saltwater resistance.

- Strong at high temperatures.

- Long lifespan in harsh conditions.

Cons:

- Very expensive.

- Harder to machine or form.

Best For:

Filtration for chemical processing plants, offshore platforms, custom filters in extreme environments, and industrial metal mesh filter material.

7. Titanium

Features:

- Strong, metal mesh filter material that remains light.

- Good resistance to corrosion, especially seawater, which is used for industrial metal mesh filter material.

- Used by metal mesh filter material manufacturers for custom metal mesh filter designs in aerospace.

Pros:

- High strength-to-weight ratio.

- It is resistant to chloride and seawater corrosion.

- It is used in medical and aerospace filtrations.

Cons:

- Very high cost.

- Harder to work, cut, and form than with steel or aluminum.

Best For:

Custom metal mesh filter applications in marine, medical, and aerospace industries, where weight and corrosion resistance are critical.

8. Galvanized & Carbon Steel

Features:

- Criteria for low-cost metal mesh filter material (also discussed in metal mesh filter material manufacturers’ catalogues)

- Galvanized steel for industrial metal mesh filter material

- Found in custom metal mesh filter products, where cost is a factor.

Pros:

- Low cost and strong.

- From metal mesh filter material manufacturers, it’s available in bulk.

- Good for disposable applications.

Cons:

- Poor resistance to strong chemicals.

- Coating can wear off.

Best For:

Cheap generic mechanical strainers, particulate filter screens, and ad hoc custom woven wire textile mesh, where cost is considered the primary driver.

Selecting The Proper Metal Mesh Filter Material

- Understand the Application Requirements: Know about the temperature, chemicals, or mechanical forces that are subjected to. The safety and functionality of an industrial metal mesh filter material need to start with selecting an appropriate metal mesh filter material.

- Consider Corrosion Resistance: For extreme environments, bi metals, choose stainless steel, titanium, or nickel alloys. Good metal mesh filter material manufacturers will be able to advise you on which alloys are best suited to your environment.

- Evaluate Strength vs. Weight: Stainless steel is the top material in terms of high-strength, heavy-duty material. For lightweight builds, custom metal mesh filter solutions are preferably made of aluminum or titanium.

- Consider Maintenance and Cleaning: Pick filter material starting from a metal mesh that is durable to cleaning means. Certain styles of industrial metal mesh filter material must be washed regularly without degrading.

- Match with Manufacturer Capabilities: An experienced metal mesh filter material manufacturer can fabricate the mesh size and shape specified for the custom metal mesh filter project.

- Balance Cost and Longevity: Steel suits short-term use, and more expensive alloys decrease the frequency of replacement. Long-term cost savings through the appropriate metal mesh filter material

- Find Cost-Effective Long-Term Solutions: Steel is inexpensive and can be relatively expensive to buy, but has a shorter service life, while more costly alloys mean less frequent replacement.

Why You Should Choose TMNetch

When we talk about metal mesh filter manufacturers, TMNetch is known for the best quality and reliability, and supplies industrial metal mesh filter material and custom metal mesh filter solutions. Here’s why:

- Material Selection Plays an Important Role: TMNetch can help you choose the metal mesh filter material list for your project.

- High-Quality Manufacturing: Modern methods result in the durability and reliability of the industrial filters.

- Made To Order: TMNetch offers custom metal mesh filter options to suit your specifications.

- Metal Mesh Filter Material List: Coverage from stainless steel to titanium, TMNetch attracted a lot of customers who need affordable metal mesh filter material list solutions.

- Global Support: TMNetch supplies global customers covering long-term supply & support in various types of industries.

FAQs

Q1. What is the most durable material for metal mesh filters?

Due to its corrosion resistance, high strength, and endurance of extreme conditions, stainless steel is the most durable metal mesh filter material. It is used in the industrial field, a very popular metal mesh filter material.

Q2. What metal mesh filter material is best for marine applications?

The advice in the maritime world is usually to use bronze or phosphor bronze. They provide higher resistance than brass to saltwater corrosion and are favored for industrial metal mesh filter material for aquatic environments.

Q3. Are custom metal mesh filters worth the investment?

The answer is yes, custom metal mesh filter designs provide an exact fit, durability, and good performance. Custom-manufactured using stainless, copper, or nickel alloys, the filters would be more durable than the average filter to meet high industrial requirements.

Conclusion

Selecting the correct material will improve the lifespan, save cost, and filter efficiently. The metal mesh filter material list is extensive, with options including stainless steel, aluminum, copper, and nickel alloys. Industrial requirements vary from one business to another; trusted metal mesh filter material manufacturers like TMNetch can also provide custom metal mesh filter solutions.