Logos on metal surfaces are powerful for branding, durability, and professionalism. If you are interested in etching a logo on metal, there are several ways of doing so. Nowadays, many industries are looking for how to etch a logo on metal. and popular logo etching on metal processes to offer the finest quality look and feel. We will discuss in this guide some of the best ways, advantages, and reasons why a business would need professional logo etching on metal products backed by TMNetch’s experience in precision chemical and laser etching.

What is Logo Etching for Metal?

In simple terms, etch logo on metal is the practice using which a mark or logo can be permanently inscribed on a metallic surface. Rather than printing or using stickers, it uses a laser to remove or alter the surface of the material to expose the design underneath, creating a permanent mark. The logo etching on metal process can be achieved by chemical, laser, or electrolysis, leaving it resistant to wear, fading, or corrosion. And this is where metal logo etching for businesses wins hands down, being one of the most dependable branding notions.

Methods for Etching a Metal Logo

When you need to etch a logo on metal, there are numerous options. The two methods have their advantages, and the applications are different.

1. Chemical Etching

Acid etching is a chemical process that removes areas of metal. It gives high precision, hence best for thin patterns and intricate designs. But it’s best suited for thicker materials.

- Best for: Thin sheets, intricate designs.

- Pros: Precise, repeatable, affordable for bulk production.

- Cons: Not ideal for heavy metals.

2. Laser Etching

Laser etching uses concentrated light beams to produce long-lasting marks. It’s a great metal and produces some clean, pro results. This is the method often used for professional logo etching on metal products such as electronics and jewellery.

- Best for: Tools for industry, electronics, jewelry.

- Pros: Fast, clean, permanent.

- Cons: Higher upfront equipment cost.

3. Engraving

Metal engraving is cut directly into the surface, resulting in a tactile, deep logo. It’s reliable, high-quality, and has a lifetime span, but is slower for mass production. It is great for high-value items, such as awards or plaques.

- Best for: Higher-end items, such as awards, tags or plaques.

- Pros: Deep, tactile feel.

- Cons: Slower for bulk production.

4. Electrolytic Etching

Electrolytic etching marks conductive metals with an electric current and salt-based solution. Not only is it eco-friendly, but you can even get fine details from it. Commonly used for metal logo etching for businesses in aerospace, medical, and industrial manufacturing.

- Best for: Logos on steel, stainless steel, and aluminum.

- Pros: Eco-friendly, detailed.

- Cons: Limited to conductive metals.

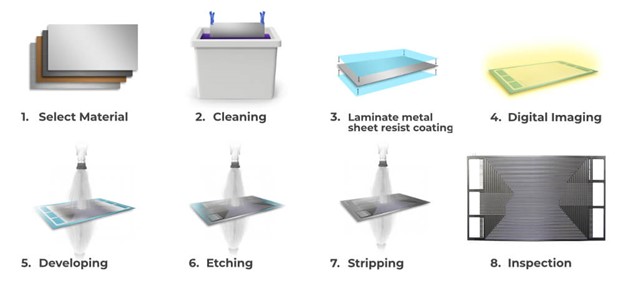

How to Etch Logo in Metal (Step by Step)

The process is different for each metal and method, but the instructions below should work with most etch logo on metal setups. It can be your guide whether you’re doing chemical, electrolytic or laser etching.

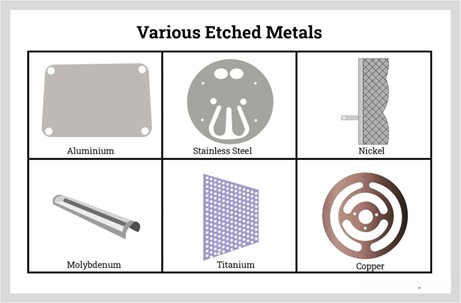

Step 1: Pick Your Metal

Establish the right base before you etch the logo on metal. Copper and brass etch fast, with warm contrast. Aluminum is light and quick to tool. Stainless steel is robust with crisp results, but does require better control. The carbon steel is robust, but does require post‑finish to avoid rust. Thicker stock requires further time or a larger output.

Step 2: Prep the Surface

A dirty surface = a dirty etch. Degrease with detergent and water, Dry well with isopropyl alcohol to remove body oils. If you need a little more bite for resists, lightly scuff with a fine abrasive pad. Wash and dry it completely – the humidity causes undercutting and irregular marks during the logo etching on the metal process.

Step 3: Create Your Design

Digital route? Use vector graphics (SVG, AI, DXF) for the sharpest edges and easy scaling. Convert fonts to outlines. Hand route? Trace design on tracing paper, then transfer (or sketch in pencil right onto the metal). Draw or transfer the artwork if you’re using stencils or transfer films, making sure to reverse the design so that when you etch the logo on metal, it has the right-side-up orientation.

Step 4: Applying the Resist (for Chemical/Electrolytic)

Mask out the areas you don’t want etched. Photoresist Film or Vinyl Stencil, Enamel Paint, Nail Polish, or Industrial Resists. Burnish edges to burst any bubbles; cracks can let chemicals seep. electrolytic etching, to achieve the most professional logo etching on metal products, over a number of parts, make sure the stencil comes in uniform contact with it.

Step 5: Time to Etch

- Chemical/Acid: Gently immerse or swab with the desired etchant (ferric chloride for copper/brass, proprietary mixes for stainless). Maintain the bath warm and agitated for uniform depth. Check the logo etching on metal process progress in short intervals.

- Electrolytic: Insert the soaked stencil, connect the anode/cathode, and insert controlled current. Sweep on in layers for added dimension/contrast. Change pads/electrolyte as they exhaust.

- Laser: Import file>Focus lens>Power/speed/frequency. Test on scrap. Add more passes for deeper marks or switch to engraving if you require depth. Fast and clean, repeatable when you etch logo on metal for lots.

Adhere to your method’s timing and safety instructions carefully. Ventilation, gloves, and eye protection are absolutely non-negotiable.

Step 6: Remove the Resist & Rinse

If chemicals are used, neutralize (e.g., baking soda solution for ferric chloride) and thoroughly rinse. Carefully peel the resist (so as not to scratch the mark). Inspect under bright light. If the edges have little burrs or a haze, clean them up with just a very light touch of fine abrasive or polish.

Step 7: Final Clean‑Up & Finish

Clean with Mild detergent, or alcohol and a soft, lint‑free cloth for that bright result. Optional finishes: passivation (stainless), clear coat or wax (carbon steel/brass), as well as a light bead‑blast to yield better sheen. These are all the little things that aid in metal logo etching for businesses keeping their look consistent and lasting longer out in the field.

Why Companies Etch Logo into Metal

Before we start learning the ways, let’s know why companies want to try metal logo etching for businesses:

- Durability: Engraved logos will never fade, paint off, or disappear over time.

- Professional Aesthetic: The etching looks so professional and adds a high-end touch to this product.

- Personalization: Simplicity in adding particular branding items.

- Etching Brand Identity: Etching makes a visual connection.

- Versatility: Ideal for electronics, machines, gas appliances, switches, and other products in promotional gifts.

Advantages of Logo Etching on Metal

When businesses choose to etch logo on metal, they get benefits over stickers or printing.

- Durable: The etched optical design is fade-resistant.

- High Quality: Ideal for professional logo etching on metal products.

- Affordable: Especially in bulk.

- Environmentally Safe: Methods such as electrolytic etching eliminate the need for hazardous chemicals.

- Versatile Design: Perfect for Logos, Barcodes & Text.

- Reliable Branding: Best for metal logo etching to give businesses legit trust.

How to Choose the Right Logo Etching on Metal Process

When you make up your mind how to etch logo on metal, please remember:

- Metal Type: Stainless, aluminum, brass, etc.

- Complexity in Design: A detailed logo may require chemical or laser techniques.

- Volume: Chemical etching is inexpensive for large quantities.

- Budget: Equipment investment vs. outsourcing balance.

- Industry Use: This service is great for professional logo etching on metal products that may require precision for use in the medical or aerospace industries.

- Eco-Friendly: Etching by electrolysis is an environmentally friendly option.

Why Choose TMNetch

TMNetch makes it simple to etch a logo on metal at scale with consistent, production‑grade results. If you need professional logo etching on metal products, we match the logo etching on metal process to your budget, metal, and timeline.

- Process Fit, Not Guesswork: Chemical, laser, and electrolytic options chosen per part; optimal path for metal logo etching for businesses.

- Material Expertise: Stainless, aluminum, brass, copper, and carbon steel handled with proven settings for clean edges.

- Support Design-to-Fixture: Starting from “how to etch a logo on metal? to jigs and stencils and even to strategies like panelization that yield repeat jobs faster.

- Quality You Can Feel: Machine Shop Spec Tolerances, Lot to Lot, Batch to Batch.

- Fast Sampling & Lead Times: Quick tests, then easy ramp to volume for production.

- Finish Options: Passivation, bead‑blast, and clear coats to protect and improve contrast.

- Cost Control: Nesting, smart batching, and re-usable tooling reduce per‑unit cost.

With TMNetch, your parts don’t just look good; they hold up in real‑world use. For reliable metal logo etching for businesses, choose a partner that treats every logo like a spec part.

FAQs

Q1: What is the optimal metal laser etching logo process?

The best logo etching on metal process is typically the laser etch process, since it’s precise, rapid, and permanent. However, bulk production is low-cost with the chemical etching.

Q2: Why go with your professional logo etching on metal products?

Professional logo etching on metal products is durable, high-end, and accurate to brand specifications. Unlike printed methods, it resists fading and wear that can affect collection logos.

Q3: Is metal logo etching for businesses expensive?

Metal logo etching is relatively cheap, especially for larger quantities. Prices depend on method, design difficulty, and machine.

Q4: Can I engrave logos on all kinds of metal materials?

Yes, you can etch a logo on metal surfaces such as stainless steel, aluminum, brass, or copper. The process could change depending on the material’s hardness and conductivity.

Conclusion

If you want your branding to last long and be premium, then go with the option of etching the logo on metal. There are chemical and laser processes for the appropriate faced logo etching on metal process to make a durable, attractive lapel pin. Metal logo etching for businesses for companies provides trust and identity, and professional logo etching on metal products results in quality. This is what makes etched logos the intelligent solution for reputable branding. For professional results at production scale, TMNetch provides reliable processes and consistent quality—a practical choice for teams that need repeatable, precise marks across parts.