The use of etched metal mesh for fashion and art, electronics, and renewable energy industries is steadily rising as this surface modification method delivers functionality, durability, beauty, and flexibility. The use of this new material is found to be a solution to problems in various disciplines due to its both practical and aesthetic character. In this article, we will discuss detailed uses of etched metal mesh and different custom uses. It will also go further to explain how it is produced, why it is selected, and the effects of the material within varying industries.

What is Etched Metal Mesh?

Etched metal mesh is a thin metal foil commonly made of stainless steel or aluminum that has been surface-treated both chemically and mechanically. This etching process can be complex, and we can design and create unique products that serve the indicated purpose and are beautiful at the same time.

Etching of metal mesh etching process

Etching uses acid or other chemicals to produce designs because these chemicals you use dissolve the metal. The final stage is obtaining a material with complex geometries that is lightweight and highly durable with a mesh structure that can be varied for specific, planned uses.

Etched Metal Mesh in Fashion

The use of Metal Mesh especially for Ladies’ shoes has now become a craze for people who always want to look unique. Fashion is another area that brought etched metal mesh into production; designers apply the etched metal mesh to accessories and clothing and even develop apparel with the etched metal mesh. Engravings also give surface depth or texture as well as contribute to the distinctive formation of patterns.

Examples in Jewelry and Garment Industry

From unique accessories to metallic clothing, etched metal mesh gives a fashionable, aggressive look. The fact that the mesh’s design is fully adjustable will be the envy of fashion statements in fine apparel.

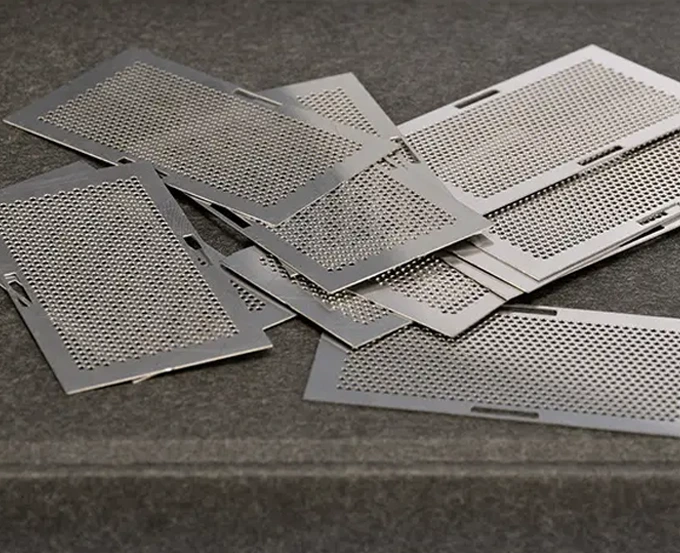

Custom Etched Metal Mesh

Adaptation of Mesh for Different Purposes

Custom-etched metal mesh allows businesses and designers to achieve precise, tailored results. For industrial use or artistic purposes, the use of the etching guarantees that the mesh is of the right size and has to be as beautiful as needed.

Industries that Fully Avail of Custom Etching

Industries such as automotive, aerospace, and fashion are all benefitting from custom-etched metal mesh. Such applications depend on the level of customization required to meet precise performance requirements while still conforming to the material’s aesthetic design concept.

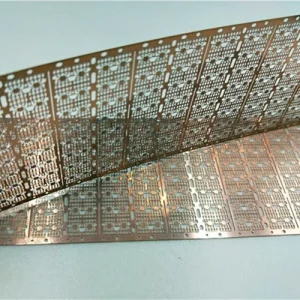

Etched Mesh in Electronics

Uses in Circuit Boards and Devices

In the milieu of electronics, etched metal mesh is central. That is why in the meshing and the mesh itself, the fine patterns can be used to develop precise components such as circuit boards, connectors, capacitors, etc. This results in designs that allow for the optimization of electronic performance through the etching done on the material.

Benefits of Heat Dissipation

In electronics, heat is always an issue that needs to be controlled and or dissipated. Metal mesh etching gives an efficient solution under this kind since it offers lightweight and durable material that serves as a heat sink. Its fine mesh structure helps in better air circulation and this is well appreciated in any device to avoid overheating.

Intricate Etched Metal Mesh

The Beauty of Complex Designs

In addition, etching metal mesh has truly advantageous characteristics since various delicate designs can easily be incorporated into it. These are not only a beautiful and practical design but also could be a suitable solution for applications in art fashion etc.

Uses in Landscape Products

Sophisticated designs of etched metal mesh are applied, for instance in art designs on facades, sunshades, and privacy screens by architects. This is because the details of the mesh make beauty and functionality interrelated hence incorporating the two in the construction of buildings.

Etched Metal Mesh for Art

Etched metal mesh is gradually gaining more application in the art world as artists and builders integrate it in sculptures, intinstallationsong other art pieces. Besides, the texture of the material offers the possibility to engrave thorough designs making it appropriate for artists.

Etched metal mesh is now used as a material for many public artworks because it reflects light, casts shadows, and comes with an element of surprise. Physicists apply it in their equations for calculating energy, force, etc., while artists apply it for creating feels and creating statutory statements in urban settings.

How Is Etched Metal Mesh Made?

The Etching Process Explained

Metal mesh fabrication starts from a flat sheet of metal through which acid or laser removes parts of the material to form the mesh pattern. This method will allow the development of designs of varying complexity depending on the specifics of the given task.

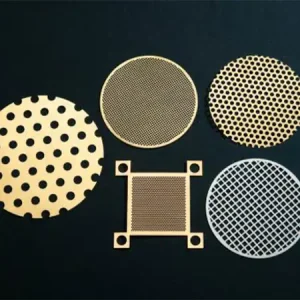

Materials Employed in Cut lines of Metal Foil

Stainless steel, aluminum, and copper are some of the widely accepted materials for etched mesh . It is for those reasons that these metals are very useful in industrial applications as well as for ornamental uses.

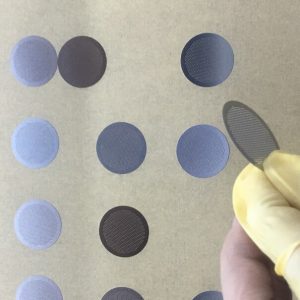

Etched Metal Mesh for Water Filtration

The Role of Mesh in Filtration Systems

Stainless steel mesh is the most important component of the modern filtration system. It is used for straining out particles in liquids such as water and oil contained in chemical industries. Because it allows only certain-sized particles to pass through, it is used widely in industries that need a high degree of cleanliness.

Application in industrial filtration

It is widely used as an industrial filter for product separation, especially in pharmacology, food, and beverages industries, to name a few, water wastewater treatment. The mesh itself is strong and precisely weaved to be used in all these demanding applications.

Why Choose Etched Metal Mesh?

Durability and Strength

What are the characteristics of etched metal mesh ? Shock and heat resistance and durability: It can go even years without degrading even under pressure. This makes it a preferred material in industries where the longevity of the building is of utmost importance.

Cost-Effective Customization

Compared to other materials, etched metal mesh is affordable to modify and results in targeted outcomes that businesses desire for their applications.

Metal Mesh Applications in Construction

Etched metal mesh is gradually finding its application in the construction industry, especially in designing the exteriors of buildings. It provides privacy at the same time it has a decorative aspect enhancing the look of a surface, making it more dimensioned and three-dimensional.

Structural Applications

Apart from the aesthetic aspect, the etched metal mesh is an efficient material for the reinforcement of concrete constructions and the construction of barriers or screens both decorative and necessary.

How Etched Metal Mesh Is Changing Industries

Innovation in Manufacturing

Etching of the metal mesh is expanding new opportunities for the manufacturing industry helped by the availability of strong but lightweight structures made from it, for use in electronics and industrial equipment production.

Creating Change

In renewable energy, etched metal mesh is used for solar panel efficiency through light-trapping capabilities. It has an involvement in a leveling up of sustainability working across many industries.

Etched Metal Mesh in Automotive Applications

Improving Efficiency and Look

New car manufacturers are finding etched metal mesh more suitable for use in the automobile industry in terms of performance and aesthetics. This material is used in air intake systems, radiators, and even car grills where the lightweight high strength is advantageous.

Custom Parts for Luxury Cars

Luxury car brands often use custom-etched metal mesh for unique, high-end design details that set their cars apart, providing a blend of beauty and function.

Etched Mesh Technology in Renewable Energy

Impact on Solar Panels

Renewable energy relies on etched metal mesh for boosting solar panels. The mesh enables sunlight to be accumulated with an improvement in the energy provided by solar systems.

Wind Energy Applications

Etched mesh is also used in wind turbines as one of the filter components to safeguard important components to work for extended periods without a significant decline in efficiency.

Medical Applications of Etched Mesh

Use in Surgical Devices

Spark-enriched metal mesh in medical applications, for producing sharpened surgical implements, stents, and implants. This makes the mesh very effective in the medical field because it can be customized according to the difficulty of the task.

This is important so that the product which will be implanted in the body of the patient will not harm his body and will last longer.

Medical technologies take advantage of the fact that etched metal mesh can be safely used in human body implantation. Also, stability allows achieving high-quality and long-lasting performance; that is why it is used for devices saving people’s lives.

Why Chemical Etching is Best for Perforated Metal Mesh Manufacture?